Assembled-type externally-restricted buckling-restrained supporting component

An anti-buckling support and assembled technology, which is applied in the direction of building components, earthquake resistance, etc., can solve problems such as inability to adjust, internal core material damage, and greater impact on manufacturing accuracy, so as to avoid overall disassembly and overall replacement, and facilitate maintenance and replacement. Avoid the effect of imprecise gap size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

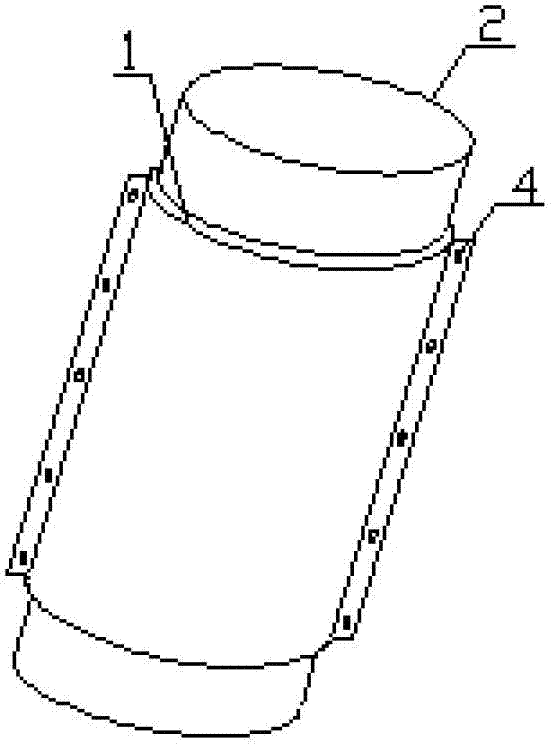

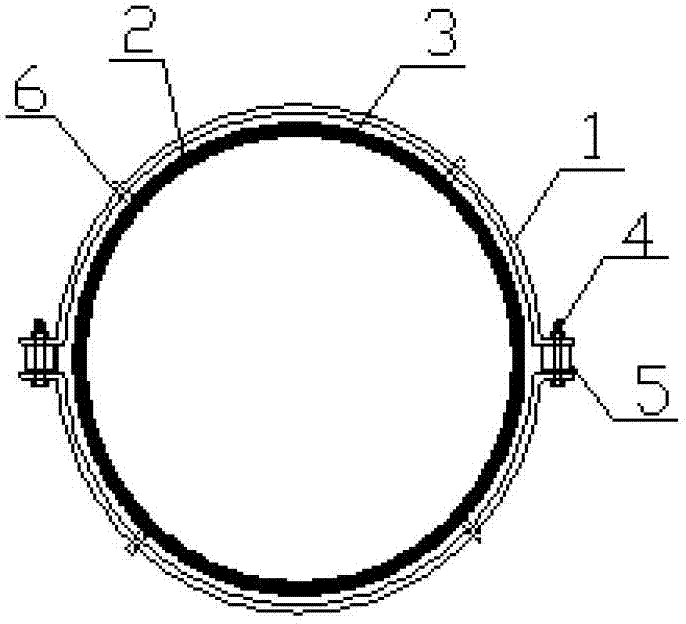

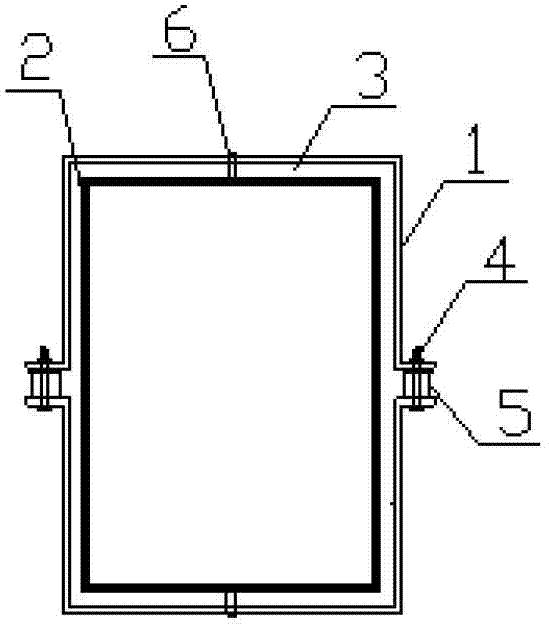

[0022] Such as Picture 1-1 , 1-2 As shown in , 2, the assembled external constraint buckling-resistant support member of the present invention includes an external constraint steel pipe and a core material steel pipe, an unbonded material layer is set between the external constraint steel pipe and the core material steel pipe, and the external constraint steel pipe Equally divided into two pieces of outer restraint steel pipe splits, the two outer restraint steel pipe splits are spliced into one body through connecting bolts, and gaskets are arranged between the spliced ends of the two outer restraint steel pipe splits; in addition, the outer restraint steel pipe splits The distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com