Rapid pneumatic automatically-controlled gas safety shut-off valve

A safety cut-off valve, gas technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of slow cut-off speed, complicated control, etc., achieve fast cut-off speed, ensure production safety, and high air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following examples, the present invention provides the specific process parameters of each device used, which is only for the sake of clarity. According to different application environments and conditions, components with other specifications can be selected or changed, or the connection mode between components can be changed, and such changes still belong to the protection scope of the present invention.

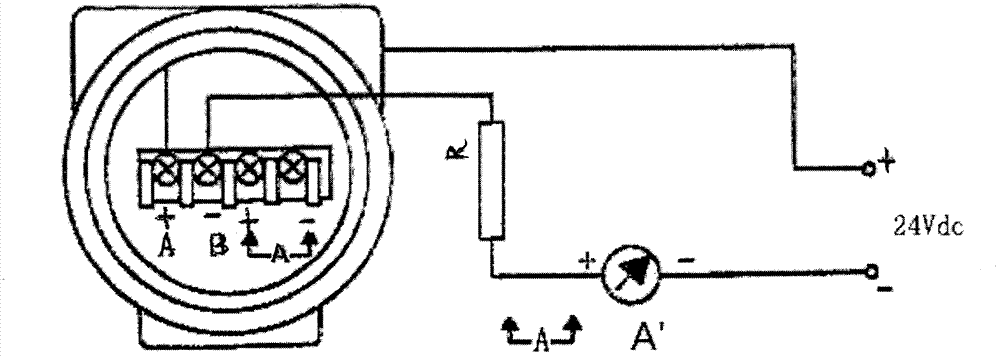

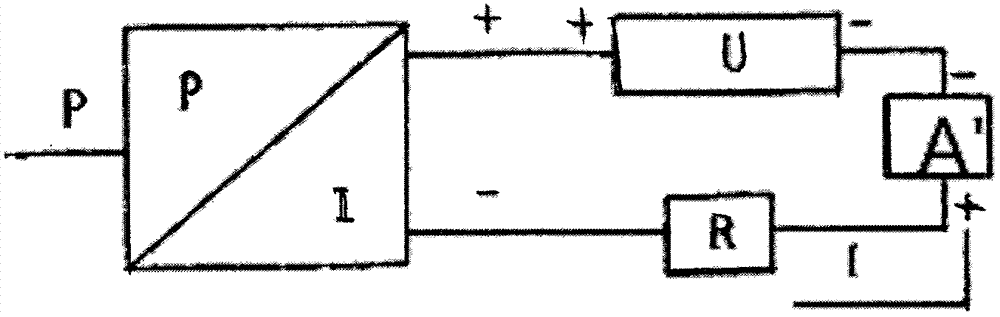

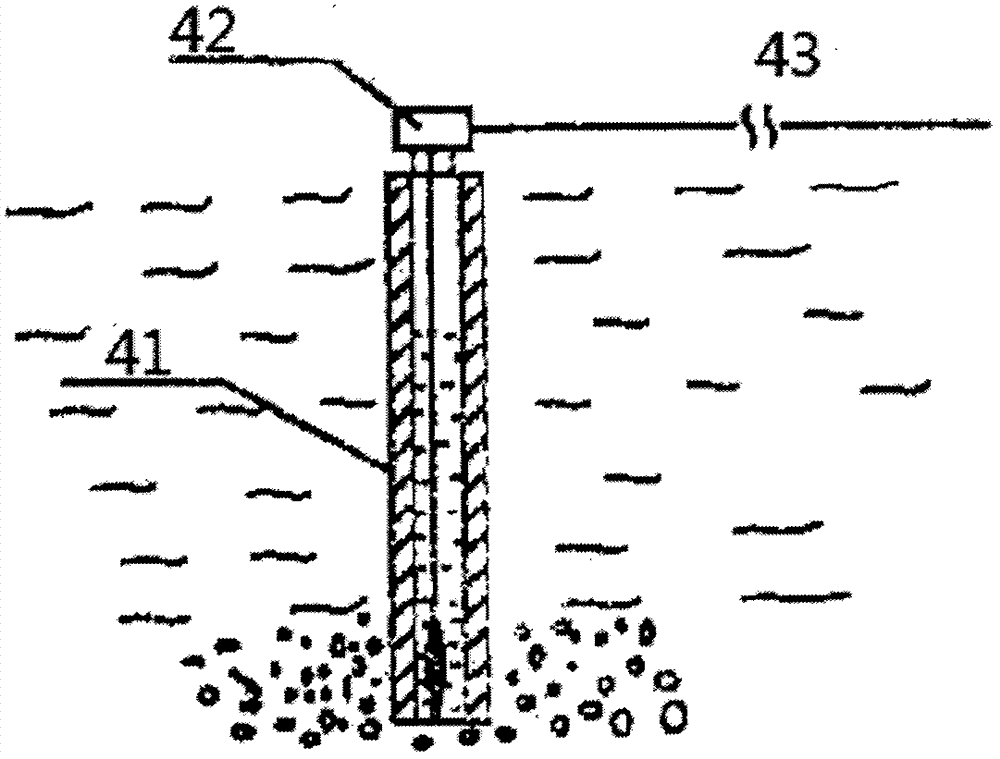

[0029] refer to figure 1 , the pneumatic automatic control fast gas safety cut-off valve of the present invention is composed of a valve body 1 and a pneumatic actuator 13 connected, the valve body 1 is cylindrical, and is sequentially installed with a sealing seat (also known as a valve seat) 2, a sealing seat from the outside to the inside. The pressure ring 3, the sealing seat and the sealing pressure ring are installed on the butterfly plate 4. The valve stem 5 connected with the pneumatic actuator passes through the entire valve body and enters the pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com