Air conditioner used thin finned tube heat exchanger

A fin-and-tube heat exchanger technology, which is applied in the field of thin-tube diameter fin-and-tube heat exchangers for air conditioners, can solve the problem that the heat exchange area becomes smaller, the state parameters of the refrigeration system deviate from the normal range, and the performance effects of changing working conditions are solved. and other problems, to achieve the effect of more pipeline processes, conducive to heat transfer and lower power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

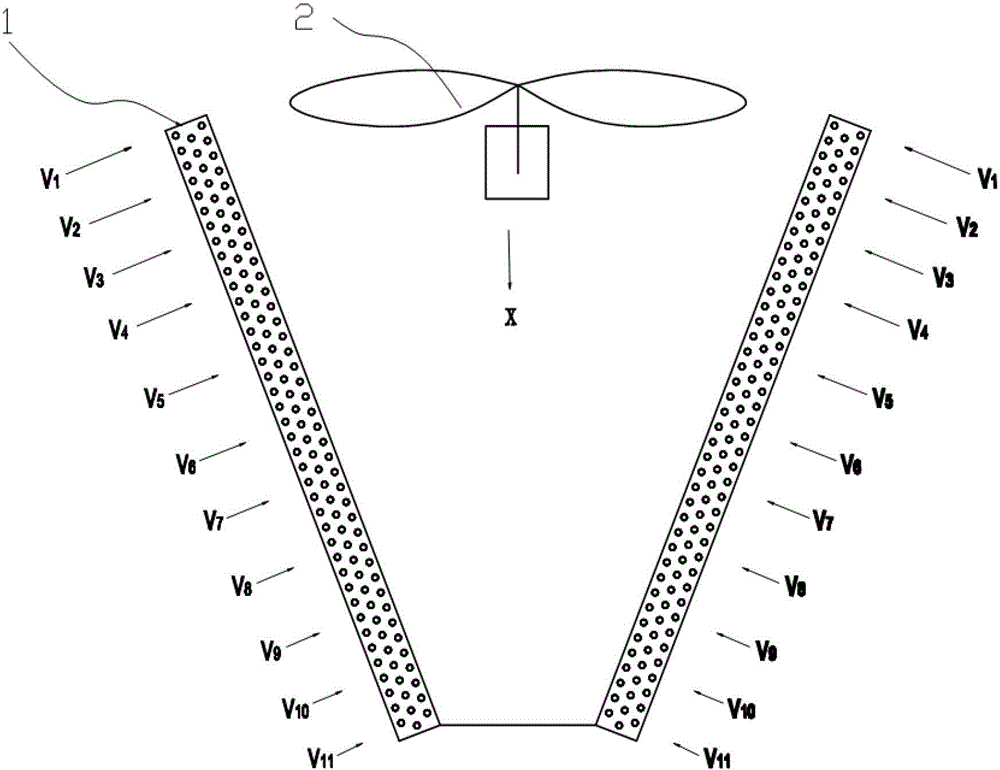

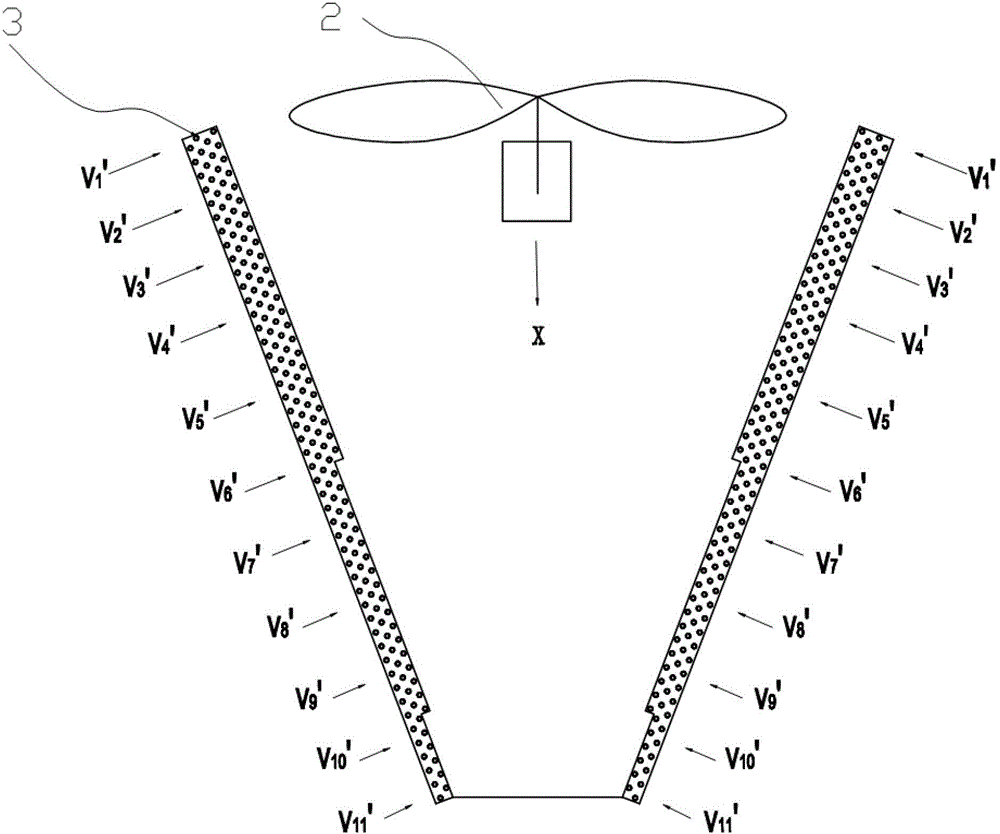

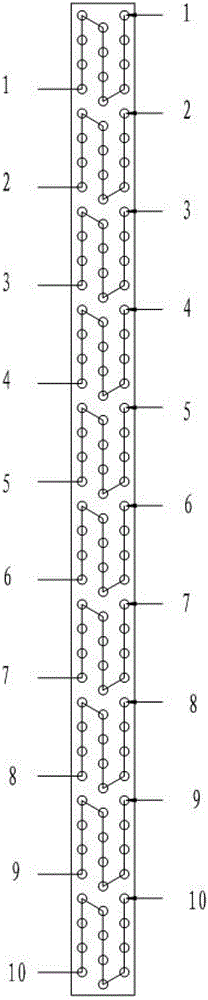

[0032] The thin-diameter finned tube heat exchanger includes a plurality of heat dissipation fins arranged in parallel with multiple rows and columns of expansion holes, and multiple rows and columns of heat exchangers that are vertically expanded with the heat dissipation fins through the expansion holes. The outside of the heat pipe and the heat transfer tube of the heat exchanger adopts fan forced ventilation to exchange heat. If the fan airflow speed is set to the X direction, the width of the cooling fins along the X direction will gradually become narrower. The number of columns of some expansion joints gradually decreases.

[0033] Such as figure 2 As shown, the width of the cooling fin gradually narrows in a stepwise manner, and its width goes through three gradient areas of A, B, and C in sequence from wide to narrow. 54.6 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com