Capillary anti-blocking structural assembly of low-temperature refrigerator and controlling method for assembly

A technology of low-temperature refrigerators and structural components, applied in refrigeration components, refrigerators, damage protection, etc., can solve problems such as lubricating oil deterioration, electric heater control, and failure to fundamentally prevent clogging, so as to prevent clogging and avoid deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

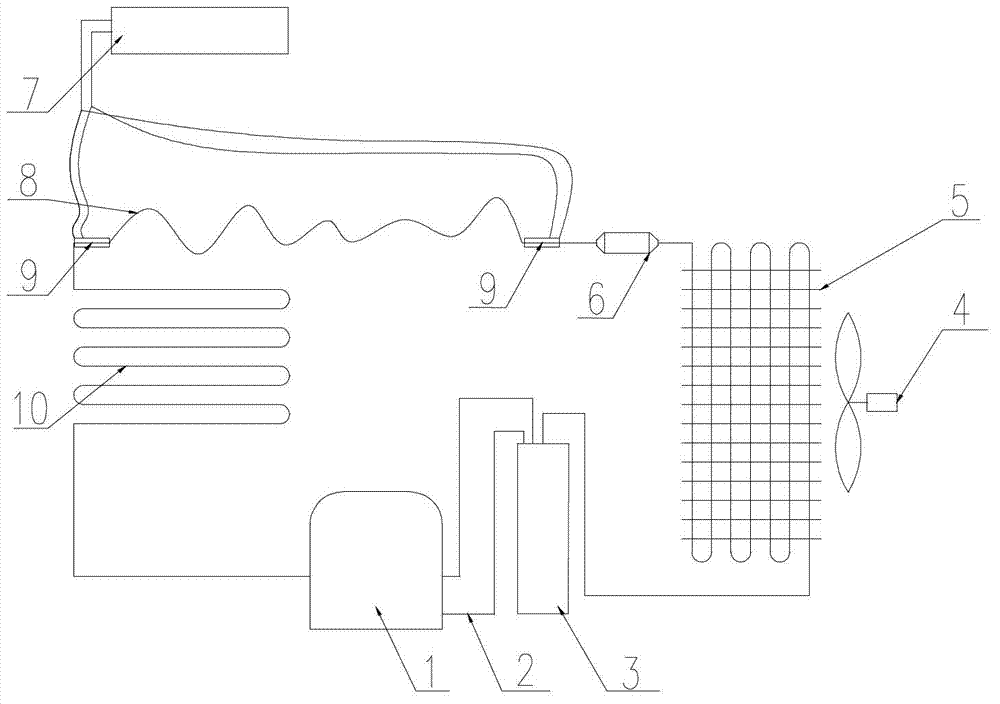

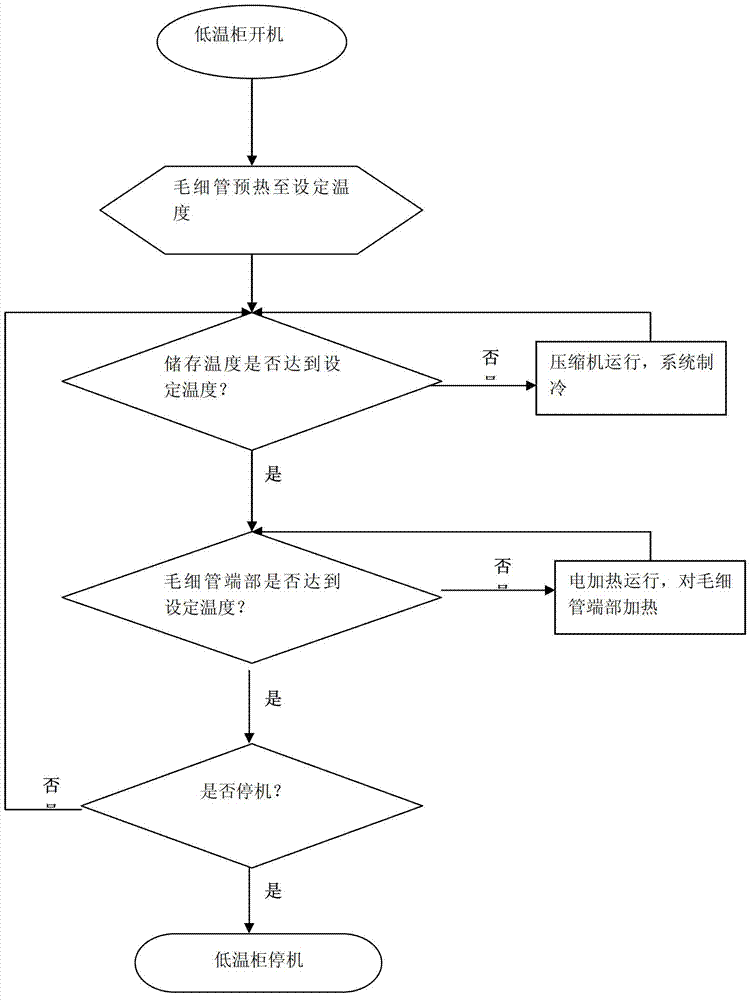

[0031] Such as figure 1 As shown, a low-temperature refrigerator capillary anti-blocking structural assembly includes: a compressor 1, an oil separator 3, a condenser 5, a dry filter 6, a capillary tube 8, and an evaporator 10, which are sequentially closed-loop connected through connecting pipelines. An oil return pipe 2 is also arranged between the machine and the oil separator, a condensing fan 4 is arranged on the condenser 5, and an oil separator 3 is arranged at the exhaust outlet of the compressor 1 to reduce the oil content in the refrigerant; A dry filter 6 is provided at the front of the capillary 8 for absorbing moisture in the refrigerant, wherein both ends of the capillary 8 are also connected with an electric heater 9 or the capillary 8 is entirely covered with an electric heater. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com