Oil immersed power transformer top layer oil temperature monitoring method based on fiber Bragg grating

A power transformer and top layer oil temperature technology, applied in the direction of physical/chemical change thermometers, thermometers, instruments, etc., can solve the threat to the safe operation of oil-immersed power transformers and reduce the operating life of oil-immersed power transformers. Strong anti-electromagnetic interference ability, simple structure, and excellent anti-electromagnetic interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

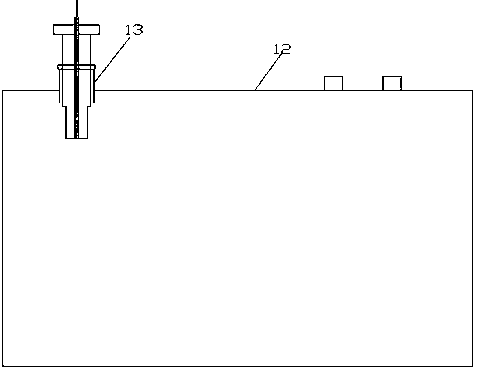

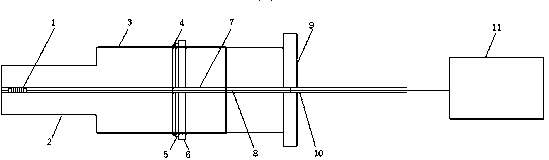

[0028] Such as figure 1 As shown: First, insert a fiber Bragg grating temperature sensor connected to the spectrum analyzer into the top layer of oil through the oil-immersed electric test hole; after stabilization, analyze the wavelength value reflected by the fiber Bragg grating according to the spectrum analyzer change, and then through the optical fiber Bragg grating temperature sensor wavelength shift and temperature change relationship , calculate the temperature of the top oil of the oil-immersed power transformer; finally, compare the measured temperature with the temperature rise standard of the oil-immersed power transformer, and judge whether the oil-immersed power transformer is in normal working condition.

[0029] It is advisable that the optical fiber Bragg grating temperature sensor is inserted into the top oil of the oil-immersed power tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com