Valve assembly with adjustable spring preload and tool kit for adjusting the spring preload

A technology of valve device and regulating valve, applied in the direction of valve device, fluid pressure actuating device, function valve type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

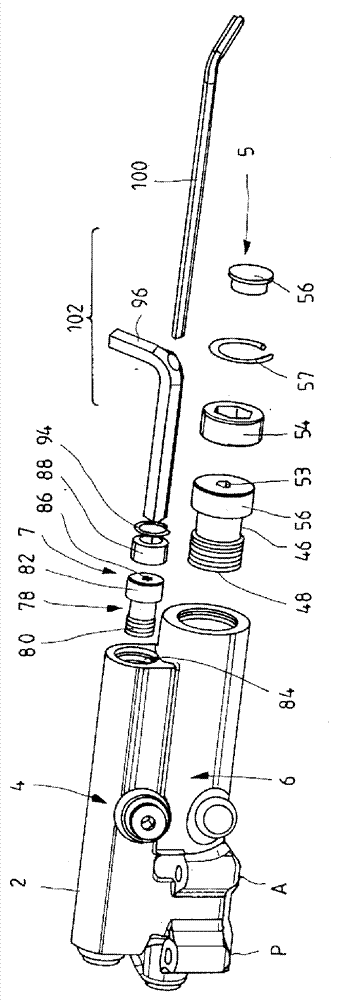

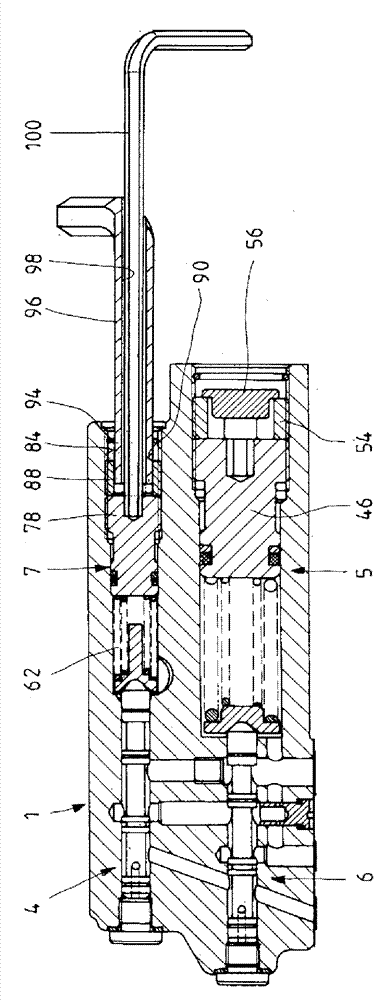

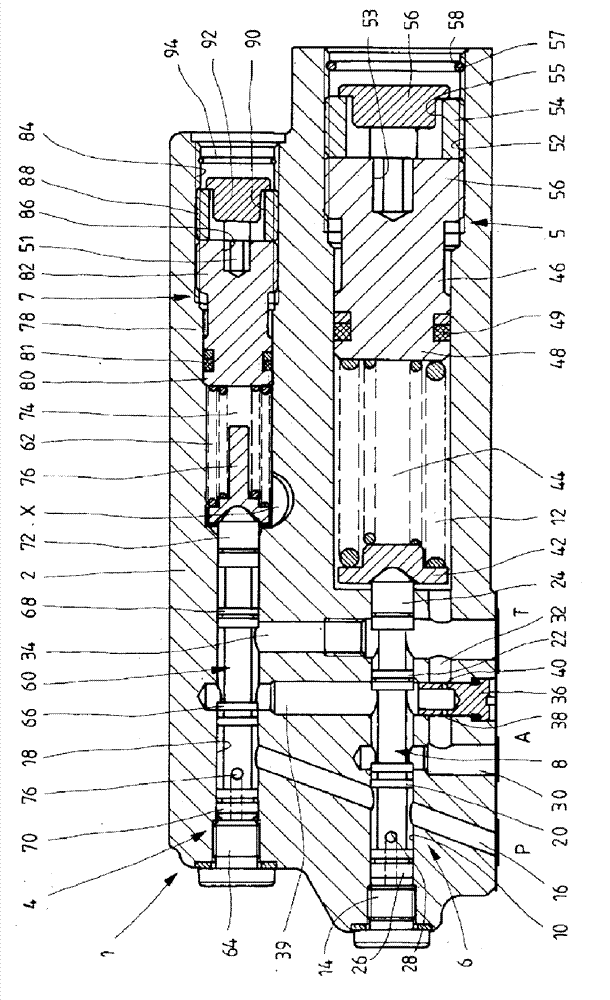

[0023] The basic construction of such a regulating valve arrangement 1 is described in detail in the prior art according to DE 101 36 416 A1 described at the outset. Furthermore, the schematic design of the pump regulator is explained in data sheet RD 92 711 / 10.07 issued by Bosch Rexroth AG, so only the structural elements which are relevant for understanding the invention are described below Also, for the sake of simplicity, reference is made to the aforementioned prior art.

[0024] exist figure 1 The regulating valve arrangement 1 shown in has a valve housing 2 in which a delivery flow regulating valve 4 and a pressure regulating valve 6 are accommodated. The pressure regulating valve 6 keeps the pressure in the hydraulic system constant within the regulating range of the pump. With the aid of delivery flow regulating valve 4 , the delivery flow of the pump can be adjusted via the pressure difference across the load, so that the pump only delivers the amount of pressure m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com