Device comprising a ring cylinder and a ring piston

A ring-shaped piston and ring-shaped cylinder technology, applied in the direction of non-mechanical drive clutches, fluid drive clutches, clutches, etc., can solve the problems of complex manufacturing process, easy scratches, and easy damage to the paint layer, and achieve low-cost manufacturing and assembly. Effect of weight, simplified assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

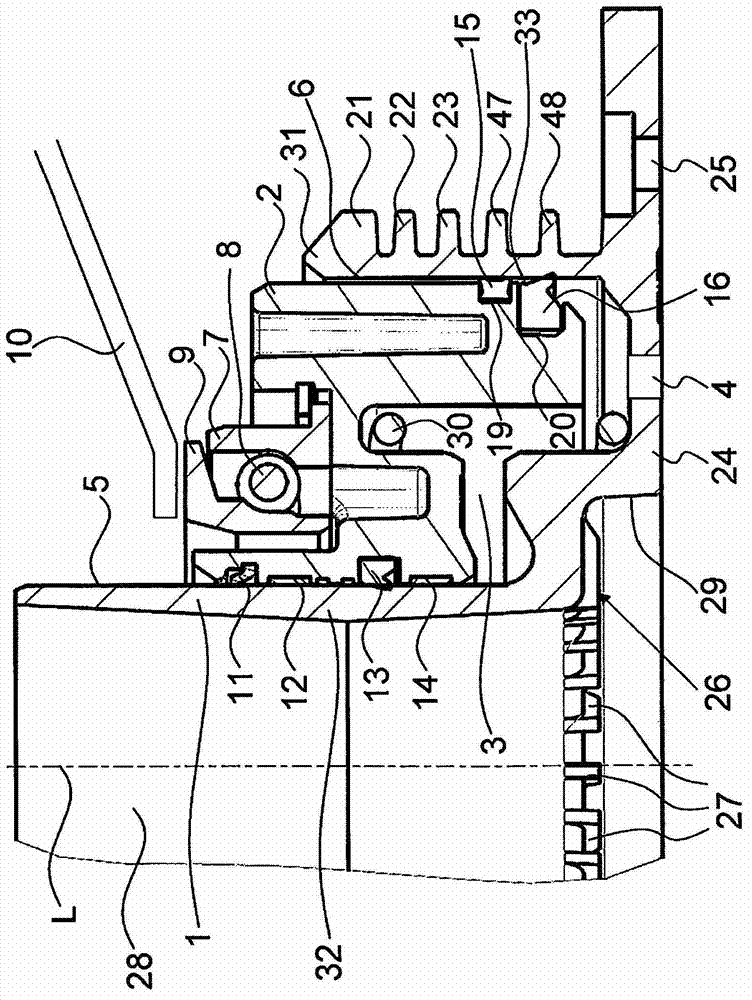

[0030] figure 1The device according to the invention is shown in section, wherein only one half of the device is shown, since the device is symmetrical and the other half, which is not shown, is configured identically.

[0031] The annular cylinder 1 can be seen with an approximately cylindrical opening 28 extending centrally in the direction of the longitudinal axis L of the annular cylinder 1 . When the annular cylinder is used as a vehicle clutch actuating device, the transmission shaft can be guided through the opening 28 . The annular cylinder 1 has a first diameter in the region of the opening 28 . In the transition region 26 , the diameter of the annular cylinder expands to a second, larger diameter until it reaches the wall 29 . The annular wall 29 serves, for example, as a receptacle for a centering flange of the transmission. thus, figure 1 The device shown can be mounted quickly and centered on the transmission. The annular cylinder 1 continues on the rear wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com