Heat clearing tablet and preparation method thereof

The technology of Qinghuo tablet and rhubarb is applied in the field of Qinghuo tablet and its preparation, which can solve the problems of inconvenient taking, many spots, low yield, etc., and achieves the improvement of quality and stability, the expansion of drug population, and the simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

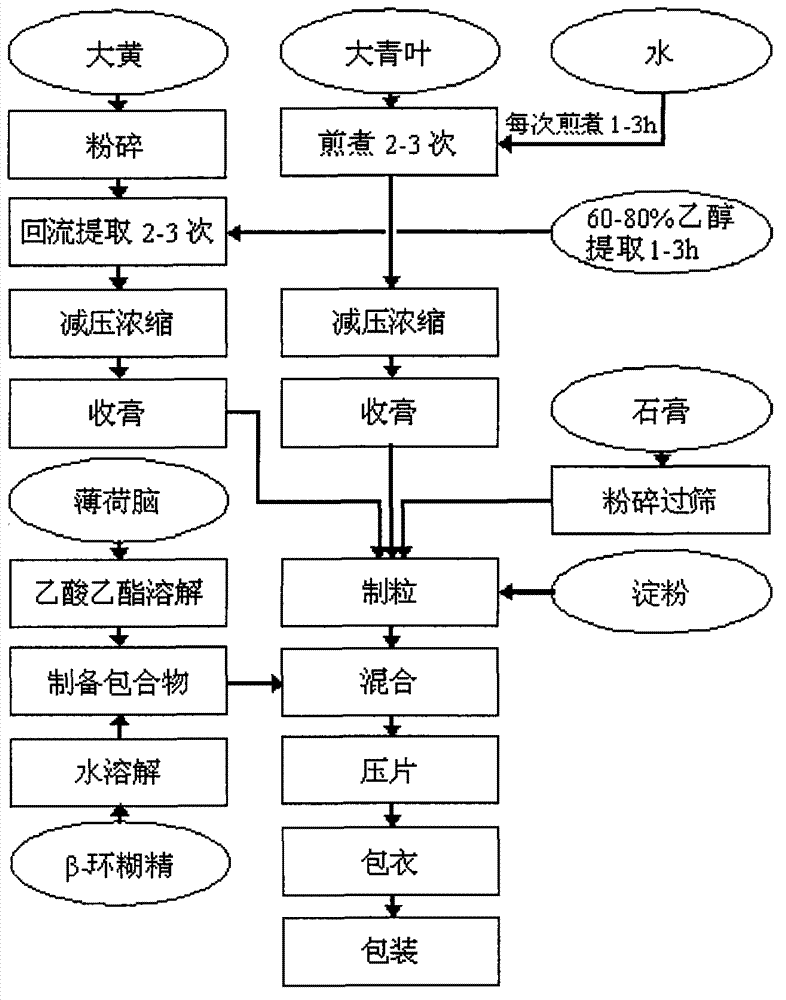

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Investigation of Rhubarb Extraction Technology

[0036] (1) Investigation on the powder yield of rhubarb: the improved process rhubarb was first crushed into coarse powder, and then extracted with ethanol under reflux, and the powder yield of rhubarb crushed into coarse powder was investigated, as shown in Table 1. The results showed that the powder extraction rate of rhubarb was above 97.5%.

[0037] Table 1 Powder extraction rate of rhubarb

[0038] Number of trials

1

2

3

Amount of medicinal materials (kg)

10

10

10

Amount of fine powder (kg)

9.82

9.78

9.80

Powder yield (%)

98.2

97.8

98.0

[0039] (2) Screening of ethanol reflux extraction conditions: the selected ethanol concentration, ethanol dosage, and reflux extraction time are the three factors investigated, each factor is taken at three levels, and the total content of emodin and chrysophanol ...

Embodiment 2

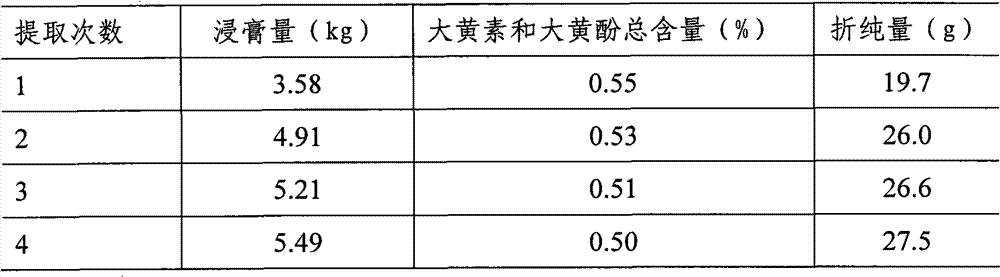

[0054] Example 2 Investigation of Folium Folium Water Decoction Process

[0055] When Folium Folium was decocted with water in the original production process, only the number of decoctions and decoction time were given, and the multiple of water addition was not given. The yield of the extract was used as the index to investigate the influence of different water additions on the yield of the extract.

[0056] Table 5 Effects of different water decoction conditions on the yield of extract

[0057] condition

[0058] The results showed that the extract yields of condition 1 and 2 were close, and the extract yield of condition 3 was low. Considering water saving, energy saving and time saving, the selected condition 2 is the water extraction condition.

Embodiment 3

[0059] Embodiment 3 Menthol inclusion process

[0060] Dissolve menthol with 10 times the amount of ethyl acetate, take 8 times the amount of β-cyclodextrin, dissolve it in the tank with 20 times the amount of purified water, and pour hot water into the jacket of the tank to make the solution temperature in the tank Keep at 38-42°C, start the stirring, slowly add the menthol solution, and keep stirring for 1 hour after the addition is complete. Pass ice-salt water into the jacket, keep the temperature of the mixed solution at 0-5°C, let it stand for 24 hours, filter the precipitate, and dry it at 50-60°C for 2 hours to control the loss on drying to ≤4.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com