Hydraulic pushing driving device in piston pushing centrifuge

A driving device, hydraulic technology, applied in the direction of centrifuges, etc., can solve problems such as troublesome installation, material pollution, oil circuit pressure reduction, etc., and achieve the effect of simple installation, stable working process and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

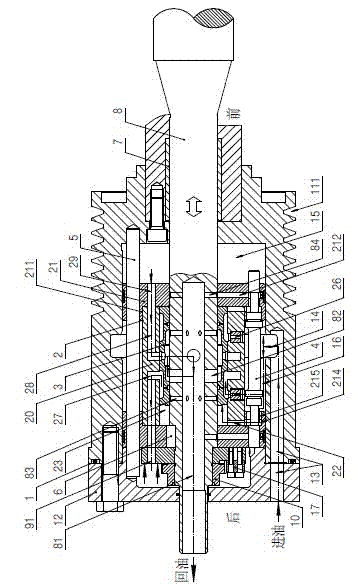

[0013] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a hydraulic pushing drive device in a piston pushing centrifuge, its structure includes a cylinder 1 made of a cylinder 11 and a cylinder head 12 arranged on the cylinder 11 through a sealing ring, and a cylinder 1 that moves through the The bottom wall of the cylinder barrel 11 and the push rod 8 of the cylinder head 12, the outer peripheral surface of the cylinder barrel 11 is provided with a timing belt groove 111, and an axial oil inlet passage 13 is opened in the cylinder barrel 11 and the cylinder head 12. The oil inlet passage 13 is formed by each section of the oil inlet passage of the cylinder barrel 11 and the cylinder head 12, and there is also a reliable sealing connection between each section of the oil inlet passage of the cylinder barrel 11 and the cylinder head 12. The sealing ring of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com