Glazing apparatus for side surface of zinc oxide resistor disc

A technology of zinc oxide resistors and power transmission devices, which is applied to the device and coating of the surface coating liquid, which can solve the problems of the appearance of the resistors not beautiful enough, the glaze layer is difficult to apply evenly, and the thickness of the glaze is uneven. , to achieve the effect of improving labor efficiency, uniform and fine glaze layer, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

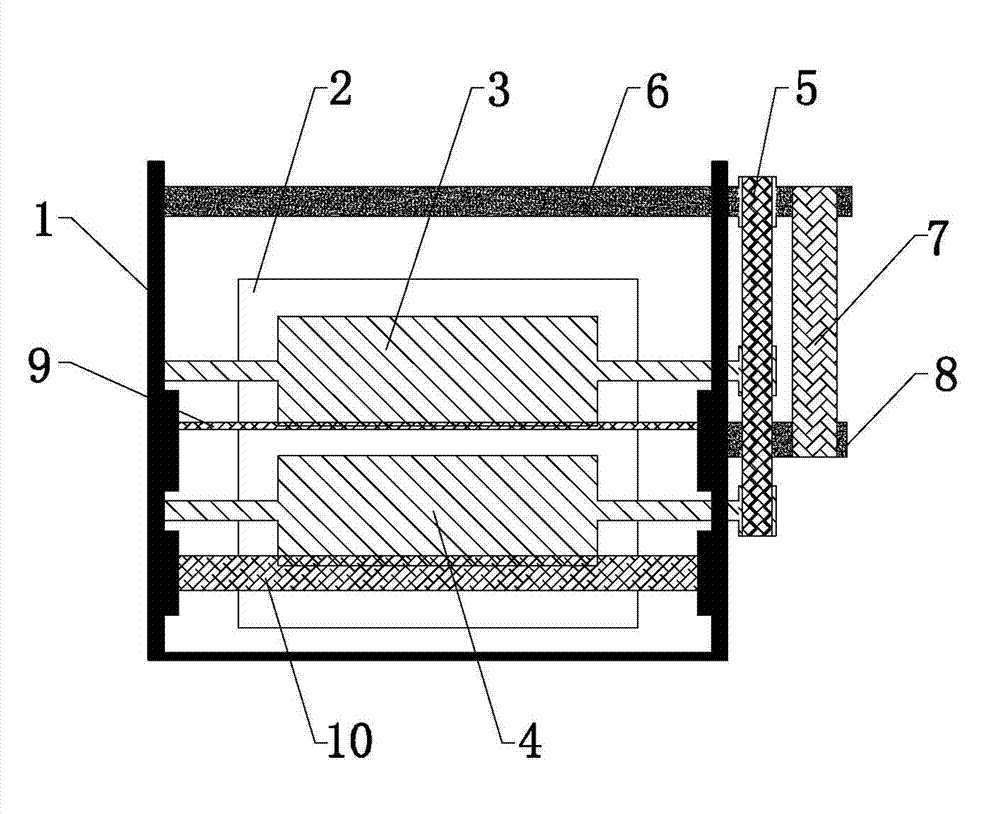

[0018] Such as figure 1 Shown: a side glazing device for a zinc oxide resistor, including a bracket, a fixed glaze pan 2 is provided in the middle of the bracket 1, and a first glazing roller 3 and a second glazing roller 3 parallel to each other are arranged above the glaze pan 2. Glazing roller 4, the first glazing roller 3 and the second glazing roller 4 can be arranged in pairs on the upper side of the glaze dish 2; and the height of the lower edge of the first glazing roller 3 and the second glazing roller 4 is low At the height of the upper edge of the glaze tray 2, the first glazing roller 3 and the second glazing roller 4 are covered with insulating glaze to facilitate. In addition, one end of the first glazing roller 3 and the second glazing roller 4 stretches out of the support 1 and is connected with the gear on the power roller 6 by the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com