Large outer hexagon bolt blank hot forging and stamping mould

A technology of external hexagon and hot forging, which is applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc. It can solve problems such as sudden cooling of molds, difficult processing, and reduced production efficiency, so as to maintain molding Shrinkage, the effect of inhibiting the generation of oxide layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

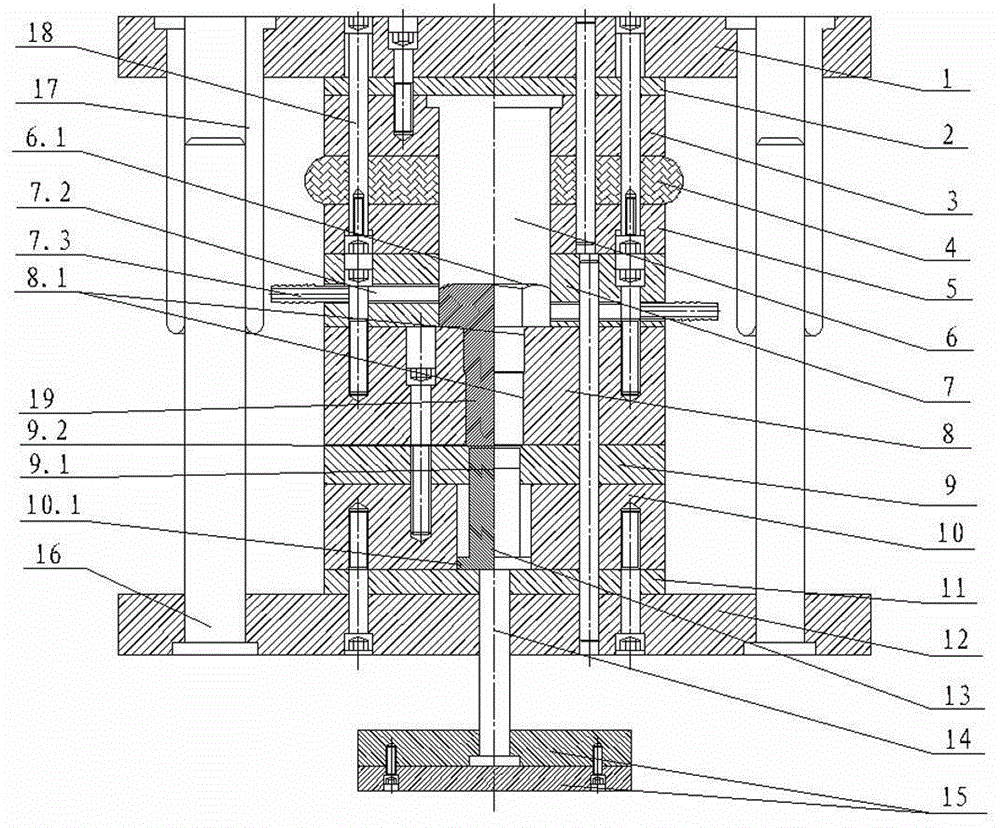

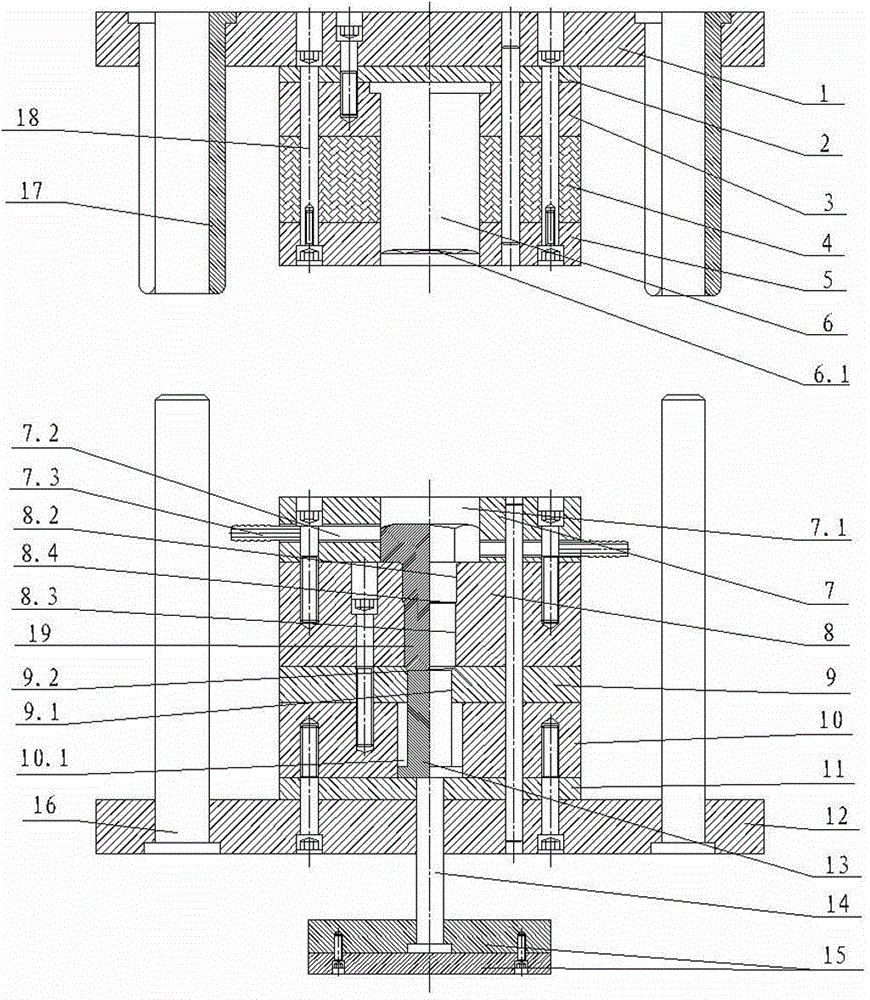

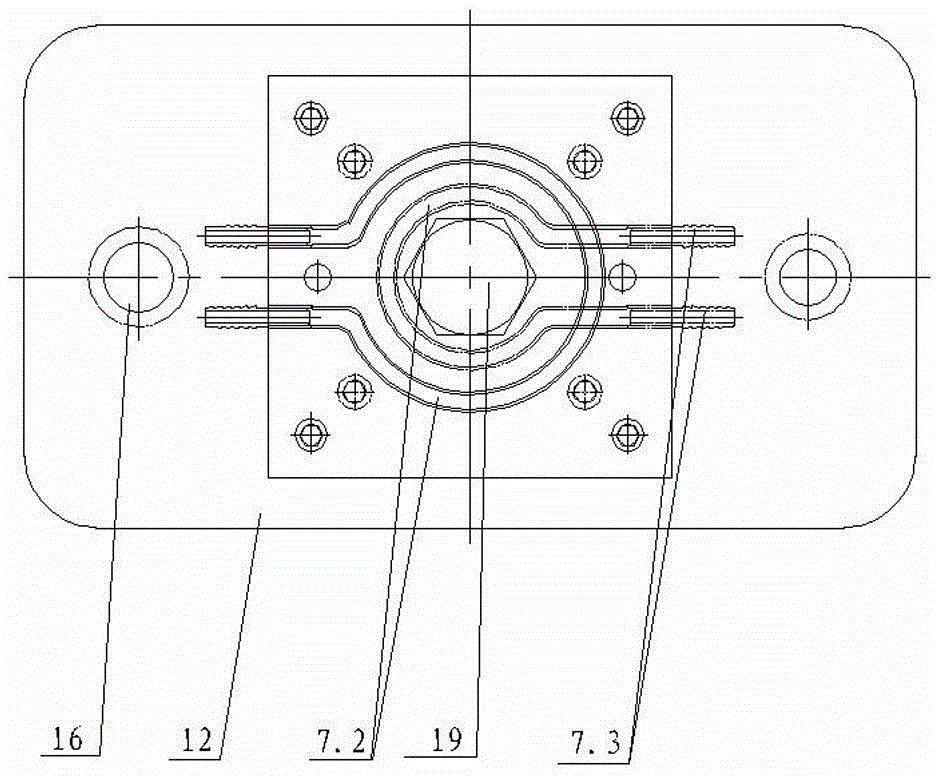

[0017] see figure 1 , figure 2 , image 3 with Figure 4 As shown, the large-scale outer hexagonal bolt blank hot forging die of the present invention comprises an upper template 1, an upper mold backing plate 2, an upper fixing plate 3, an elastic body 4, an upper forming plate 5, an upper punch 6, a first forming plate 7, The second molding plate 8, the ejector pin cover plate 9, the auxiliary ejector pin cover plate 10, the lower mold backing plate 11, the lower template 12, the ejector pin 13, the auxiliary ejector pin 14 and the auxiliary plate 15, the upper template 1, the upper mold The backing plate 2, the upper fixing plate 3, the elastic body 4, and the upper forming plate 5 are sequentially connected by combination screws 18, the first forming plate 7, the second forming plate 8, the ejector pin cover plate 9, and the auxiliary e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap