Full-automatic gravity casting apparatus

A gravity pouring, fully automatic technology, applied in casting equipment, metal processing equipment, pig iron foundry, etc., can solve the problems of oxide skin and unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

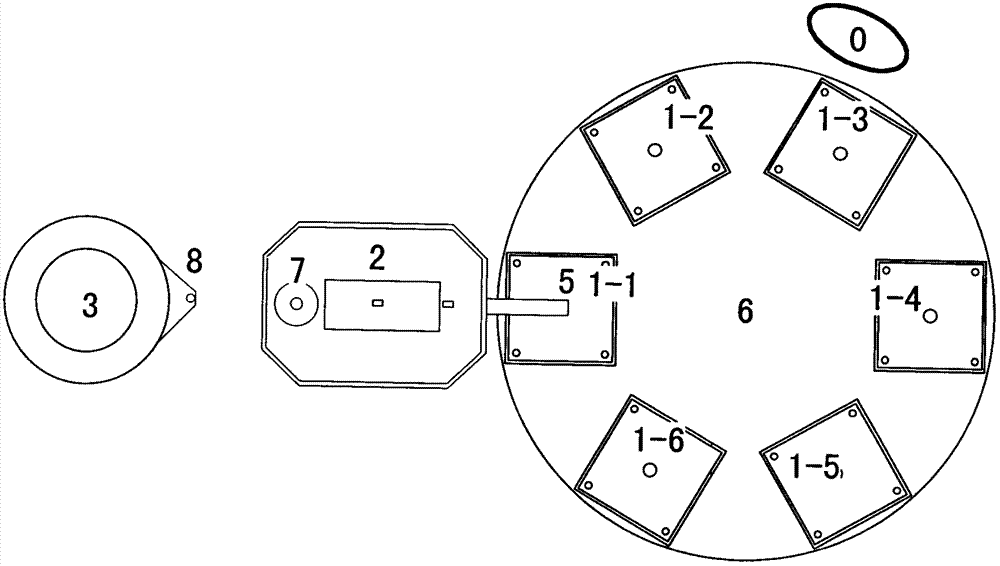

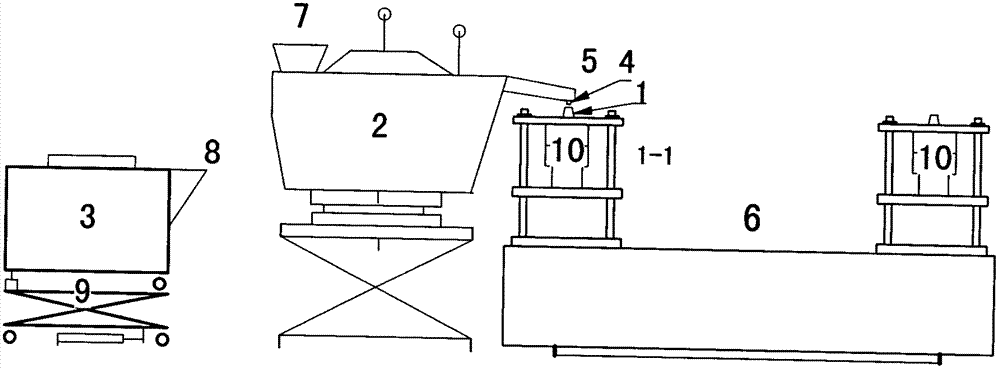

[0006] The automatic gravity pouring equipment of the present invention such as figure 1 ,Such as figure 2 As shown, the thermal insulation gate (1) is pressed by mullite polycrystalline cotton and installed on the metal mold (10) of the pouring machine (1-1 to 1-6), and each metal mold (10) uses one The heat preservation gate (1); the dosing furnace (2) is equipped with an electric heating long nozzle (5); the outlet of the electric heating long nozzle (5) is equipped with a degassing protection device (4); the degassing protection device (4) is installed on the nozzle ( 5) Outer edge of the mouth, before each injection of aluminum liquid, the mouth of the electric heating long nozzle (5) is aligned with the heat preservation gate (1), and the degassing protection device (4) first injects protective gas to make a protective climate, so that the flowing aluminum liquid Always pass through in a heated protective climate, no oxidation, no dripping and skinning during the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com