Compression molding method and compression molding machine

A pressing molding and forming machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low production efficiency and low positioning accuracy, and achieve the effects of high production efficiency, simple structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

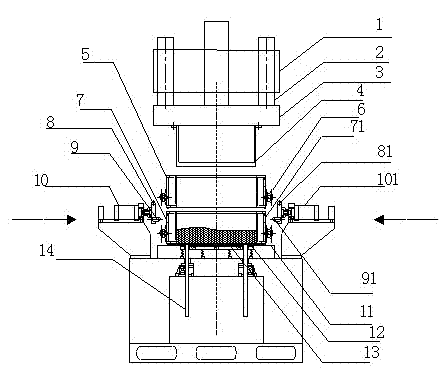

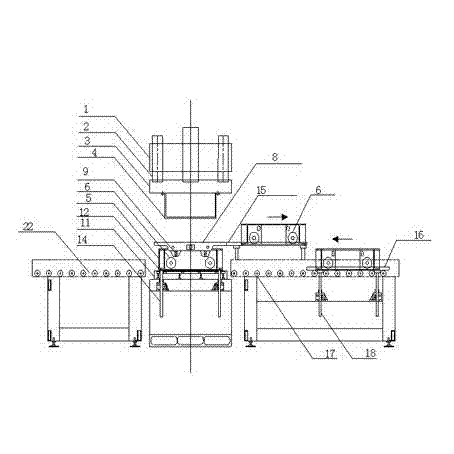

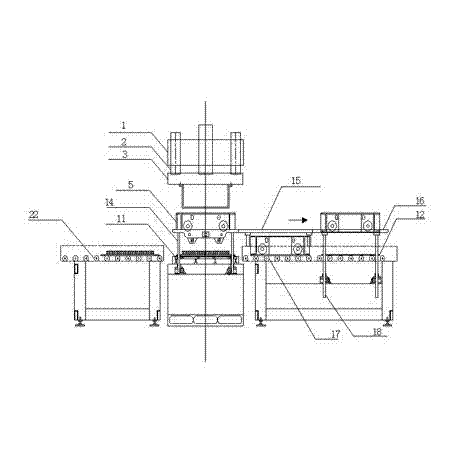

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] In the figure: press upper mold beam 1, press guide column 2, press movable block 3, die head 4, mold frame 5, pulley 6, positioning hole 7, movable return link 8, positioning pin 9, positioning power body 10 , Press down platform 11, mold bottom plate 12, floating wheel assembly 13, lifting jack 14, fixed return connecting rod 15, lifting connecting rod 16, raceway platform 17, lifting jack 18, floating wheel support plate 19, Spring 20, floating wheel 21, output raceway platform 22, positioning hole 71, movable return link 81, positioning pin 91, positioning power body 101.

[0030] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 5 As shown, the press molding machine of the present invention comprises a press upper mold beam 1, a press guide column 2, a press movable block 3, a die head 4, and a pressing lower platform 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com