Method for assembling a mobile crane and mobile crane

A technology of mobile cranes, cranes, applied in the direction of cranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

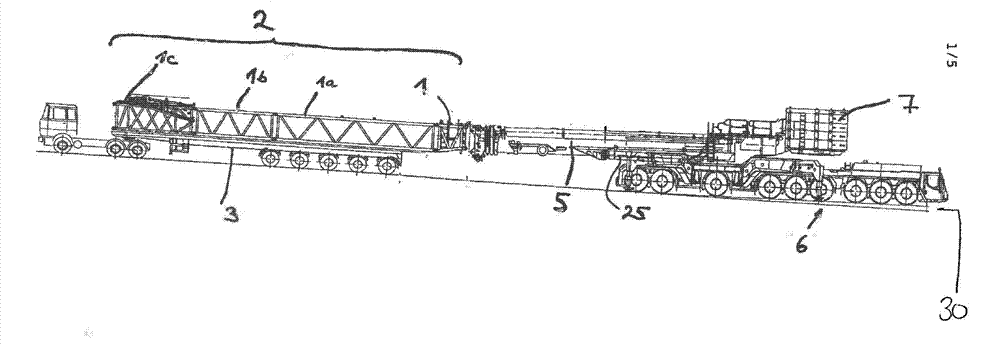

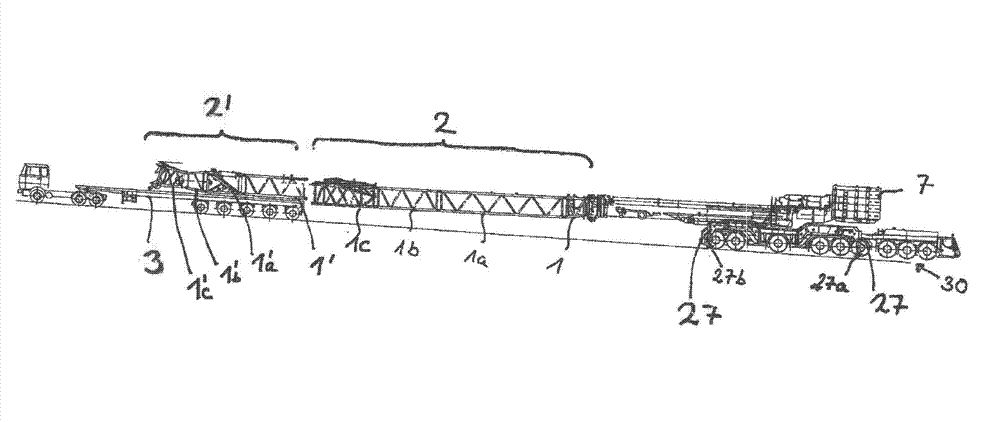

[0035] In the descriptions in the following sections, with the help of the attached Figures 1 to 6 A specific embodiment of the method according to the invention for assembling a telescopic crane and an embodiment of the telescopic crane are described.

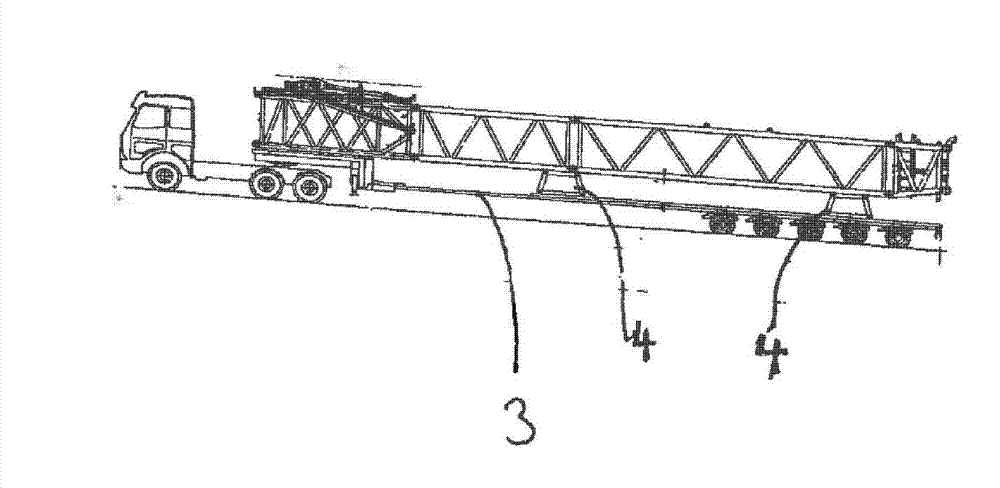

[0036]The required jib combination for a telescopic mobile crane is determined in the crane service plan. To extend a crane main jib, one or more boom extensions should be fitted on top of the main jib in order to prepare the crane for the planned crane work. The corresponding jib extension consists of individual truss elements 1, 1a, 1b, 1c, 1', 1a', 1b', 1c' which have been combined with one another before being transported to the installation location and which are mostly in in working condition. Possible preassembled boom extensions are, for example, main boom extensions or also fixed or pivotable fly booms.

[0037] In the central part of the crane present here, the complete jib assembly disassembled into the individu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com