Work car for main cables of suspension bridge

A technology for suspension bridges and work vehicles, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as safety impact, increased maintenance difficulty, structural restrictions, etc., to reduce construction difficulty, improve maintenance efficiency, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

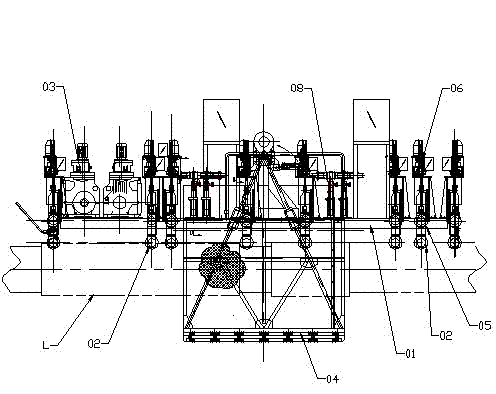

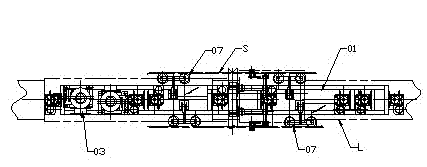

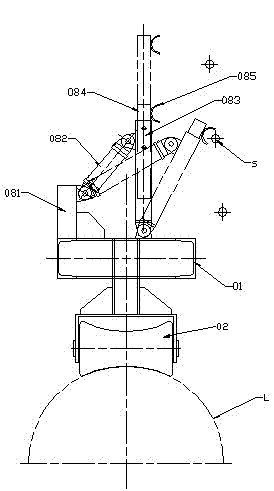

[0013] Such as figure 1 , figure 2 As shown, the main cable working vehicle of the suspension bridge includes a frame 01, and a plurality of traveling wheels 02 are arranged longitudinally at intervals at the bottom of the frame. The frame is seated on the main cable L through the traveling wheels and can move along the main cable , the front part of the frame is provided with a winch device 03 that provides power for walking and movement; a hanging basket 04 that is hingedly connected with the frame is also suspended on the frame; each walking wheel is installed on a lifting seat 05 that can be A lifting seat is driven and lifted by a power unit 06 independently installed on the vehicle frame. The two sides of the vehicle frame 01 are respectively provided with several side rollers 07, and the two sides of the vehicle frame are supported by the side rollers on the handrail wire ropes above the two sides of the main cable of the cable bridge.

[0014] During the frame walki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com