Method for driving parameter optimization experiment of high-pressure common-rail high-speed electromagnetic valve

A high-speed solenoid valve and driving parameter technology, applied in the direction of engine testing, engine components, machines/engines, etc., can solve problems such as simulation correction, many human factors, failure to test by conventional means, and failure to produce finished products, etc., to achieve rapid reset , improve service life, reliable suction and fast shut-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

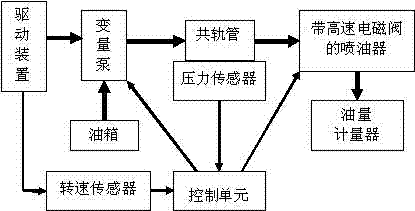

[0020] A high-pressure common rail high-speed solenoid valve driving parameter optimization test method, mainly including a driving device, a variable pump, a common rail pipe, a fuel injector with a high-speed solenoid valve, a fuel tank, a fuel gauge, a speed sensor, a pressure sensor, and a control unit and other components, the principle block diagram of this method can be divided into three parts: drive device, oil circuit and circuit;

[0021] In the oil circuit part, the oil running direction is: fuel tank→variable pump→common rail pipe→fuel injector with high-speed solenoid valve→oil quantity meter. The variable pump has two oil ports, and the oil inlet is connected to the fuel tank. The oil outlet is connected to the inlet of the common rail pipe, the outlet of the common rail pipe is connected to the inlet of the fuel injector with high-speed solenoid valve, and the outlet of the fuel injector with high-speed solenoid valve is connected to the fuel gauge;

[0022] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com