Automatic grain discharging machine for semiconductor refrigerating sheet

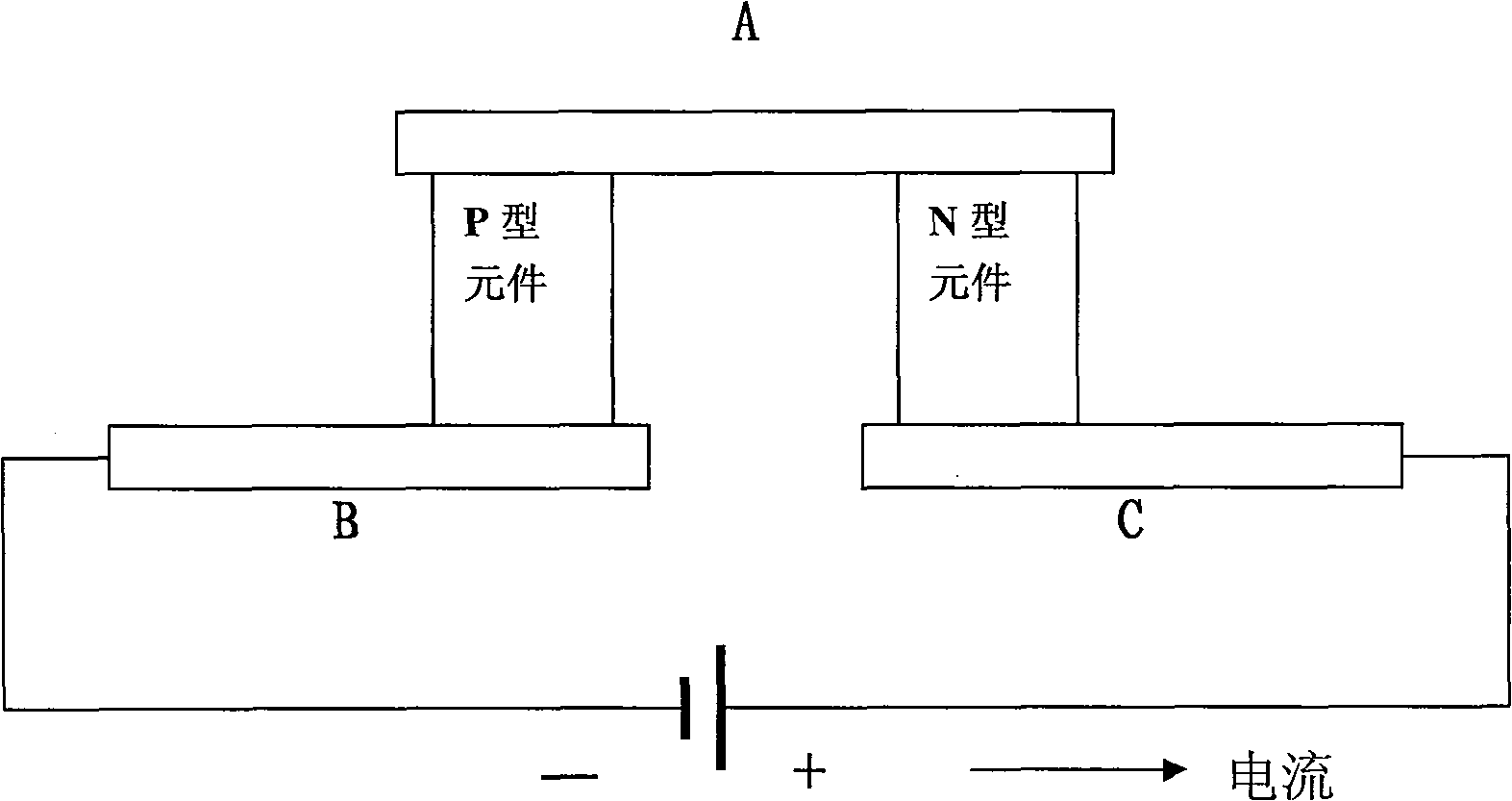

A technology for refrigerating chips and semiconductors, applied in the field of semiconductor refrigerating chips manufacturing equipment, can solve the problems of high labor intensity, affecting productivity, and increasing production costs, and achieve the effects of reducing production costs, improving production efficiency, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

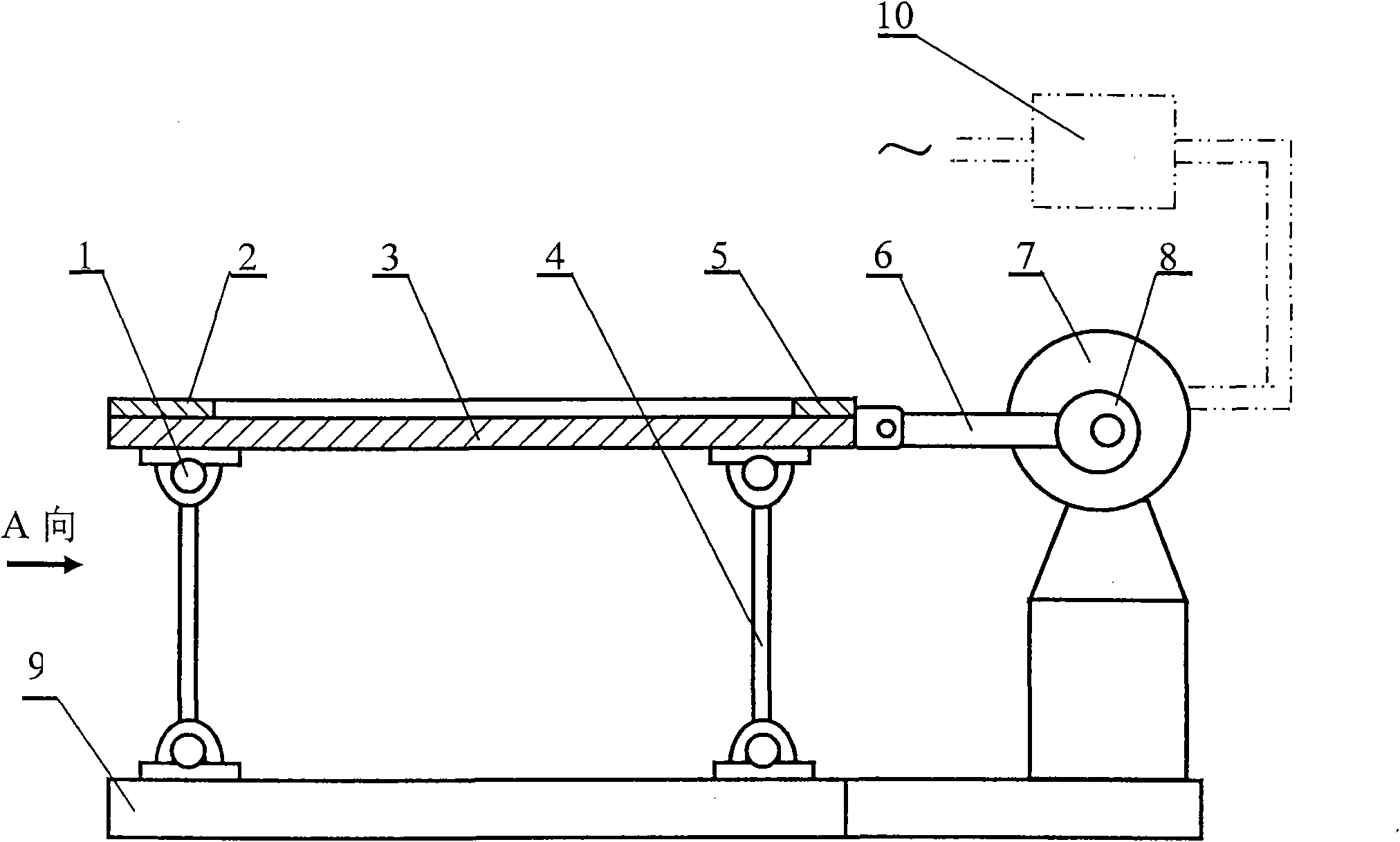

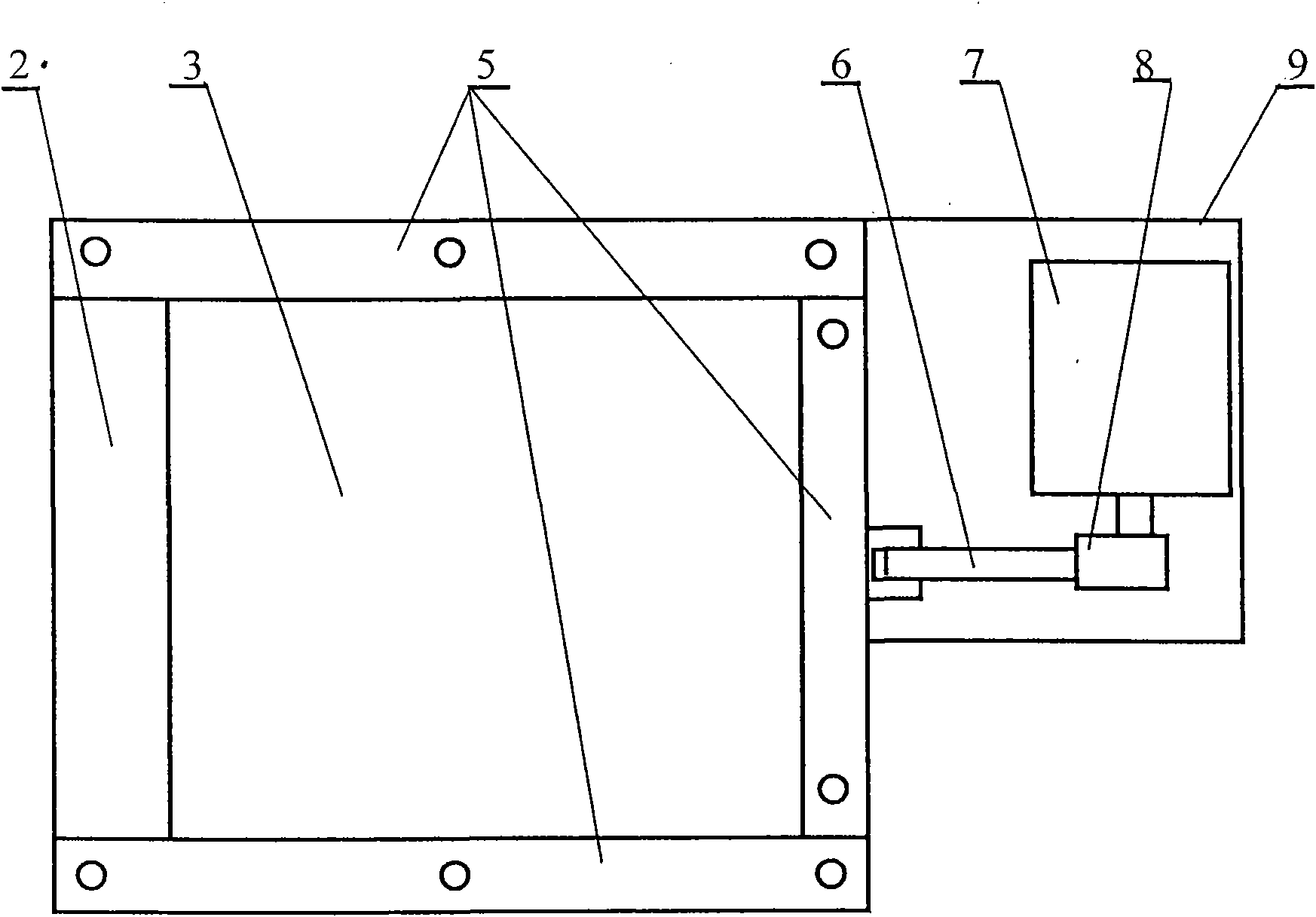

[0015] exist figure 1 , figure 2 , image 3 In the embodiment, the motor 7 of a semiconductor refrigeration chip P and N type grain automatic granulator of the present invention adopts a speed-adjusting motor, which is connected in series with the frequency converter 10; the 8 bearing assemblies 1 are purchased parts; the base 9 adopts a thickness of For 15mm-20mm steel plate, its shape is The eccentricity of the eccentric wheel 8 is 1 mm-3 mm, one end of the connecting rod 6 is fixedly connected with the eccentric wheel 8, and the other end is movably connected with the granulation platform 3; It is made of steel plate, the length and width are 30 cm to 60 cm, and the front surface is smooth. The three fixed ribs 5 and one movable rib 2 set on the front of the pellet discharge platform 3 are long strips of thin steel plates, and their thickness is 2.2 mm -3.0mm, 2cm-3cm wide, the enclosed rectangular recess can just set 8-12 granule discharging dies, the back of the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com