Method for calibrating and checking cross section measurement platform

An inspection method and technology of a measuring platform, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to guarantee the real-time accuracy of a cross-section measuring platform, reduce equipment costs and labor costs, ensure measurement accuracy, and avoid measurement effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] This measuring table meets the following production conditions: plate thickness: 0.2-5mm, width: 12.5-25mm.

[0024] Calibration method implementation of the cross-section measuring bench:

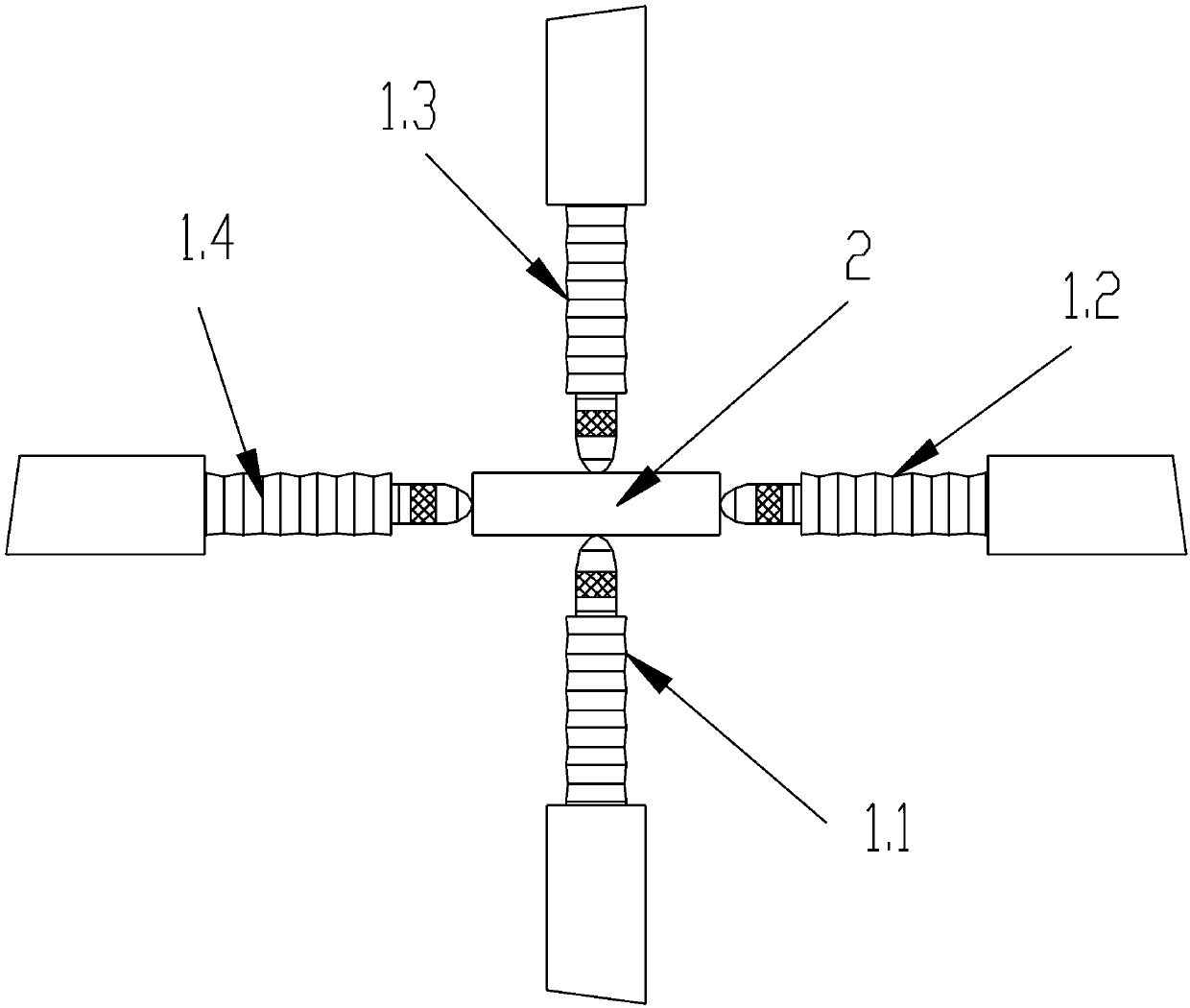

[0025] see figure 1 , firstly, the standard sample 2 is sent to the calibration station, and the calibration value is obtained after measuring the standard sample 2;

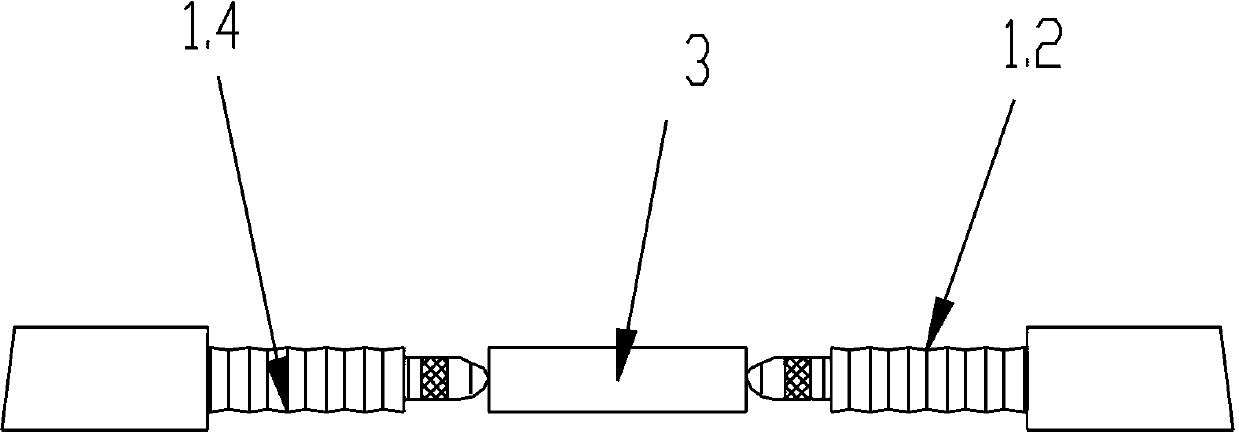

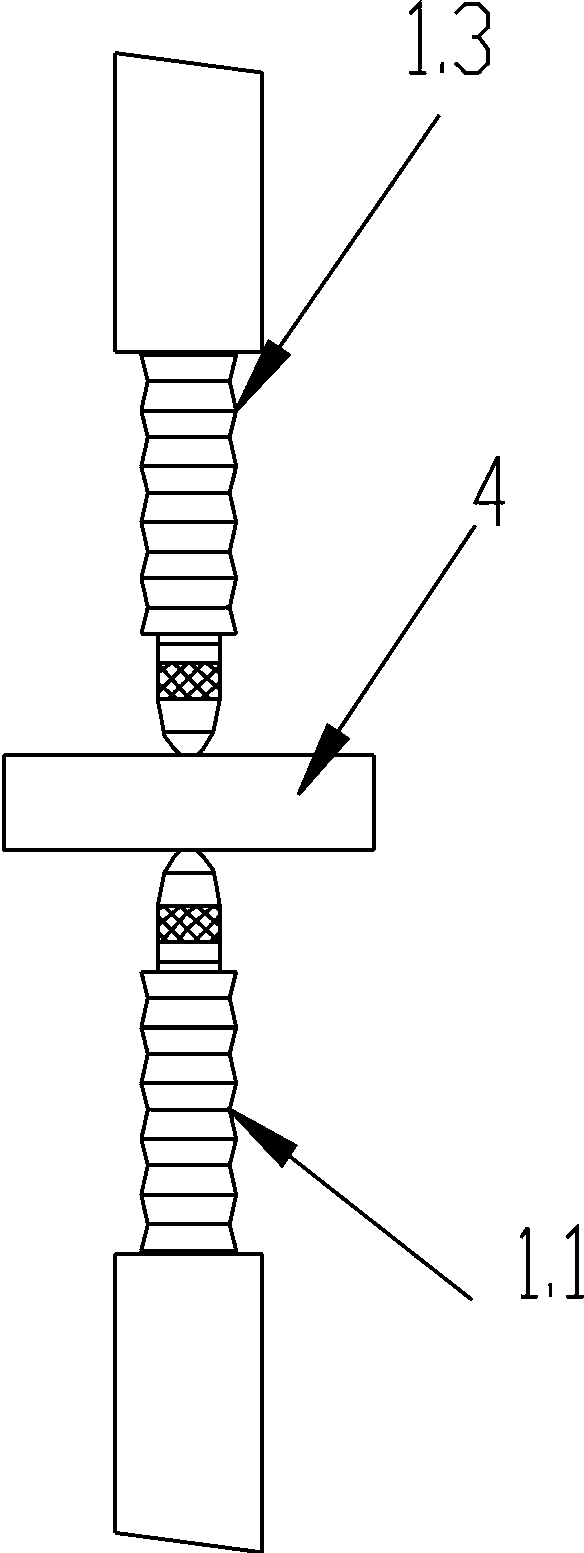

[0026] The specific process is: a pair of displacement gauges (the first displacement gauge 1.1 and the third displacement gauge 1.3) facing each other in the thickness direction respectively measure the thickness of the standard sample 2 to obtain the calibrated thickness value A1; A pair of displacement gauges (the second displacement gauge 1.2 and the fourth displacement gauge 1.4) measure the width of the standard sample 2 and obtain the fixed value of the calibration width A2;

[0027] Calibration thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com