Fixture suitable for circuit board testing table

A technology for testing machines and circuit boards, applied in the field of fixtures, can solve the problems of loose main structure of fixtures, unstable circuit board testing, and reduced customer productivity, etc., to achieve easy opening and closing of fixtures, humanized operation, and difficult loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

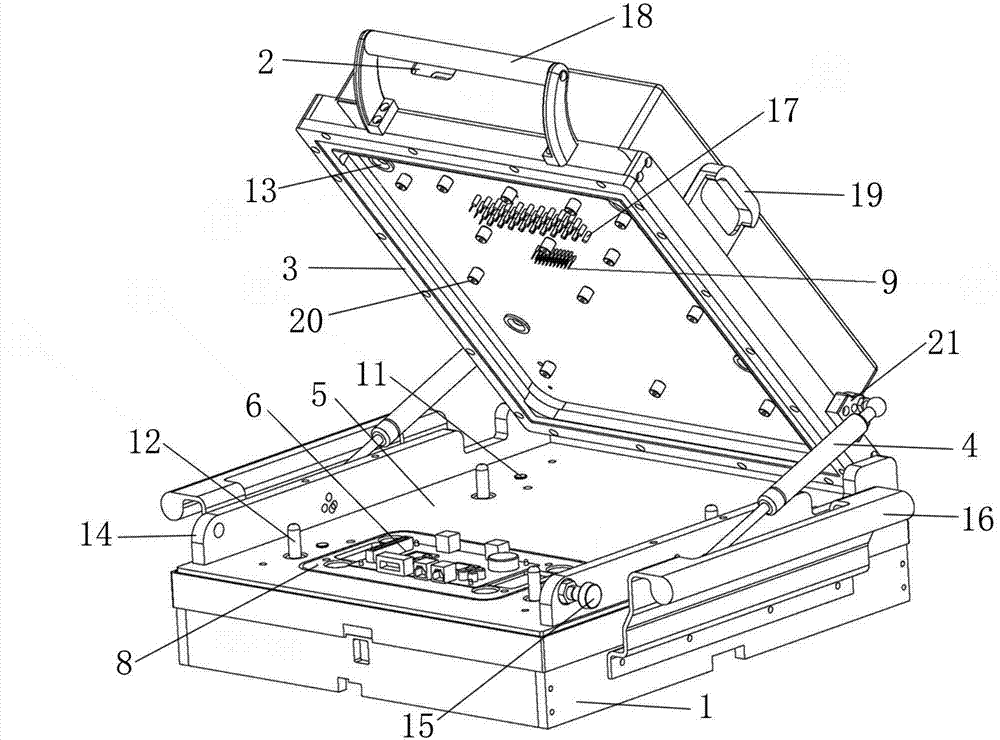

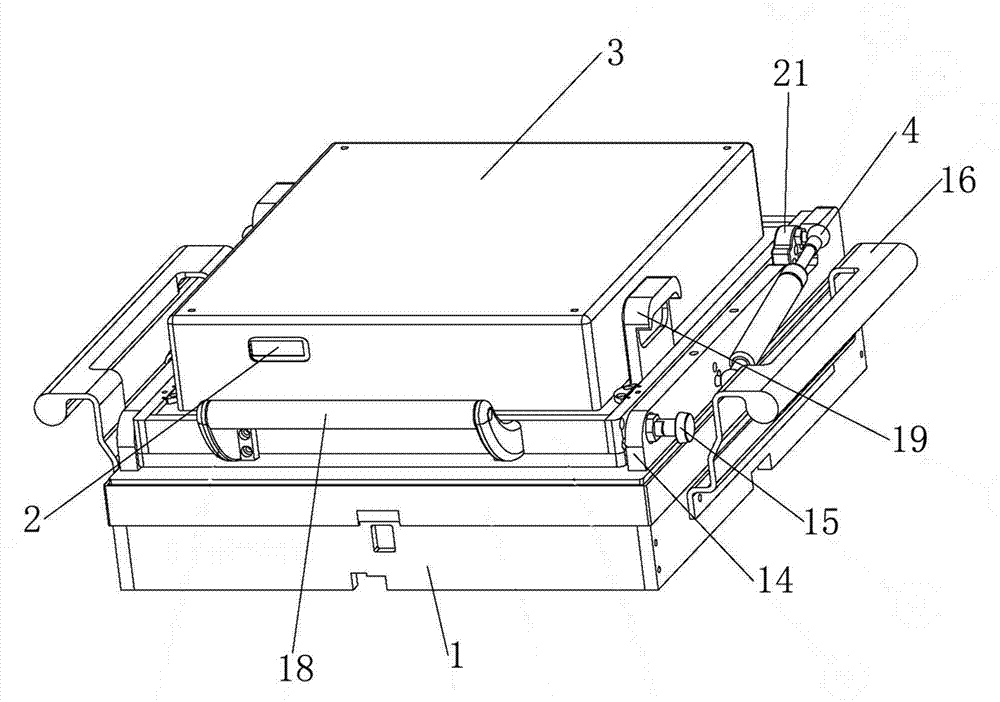

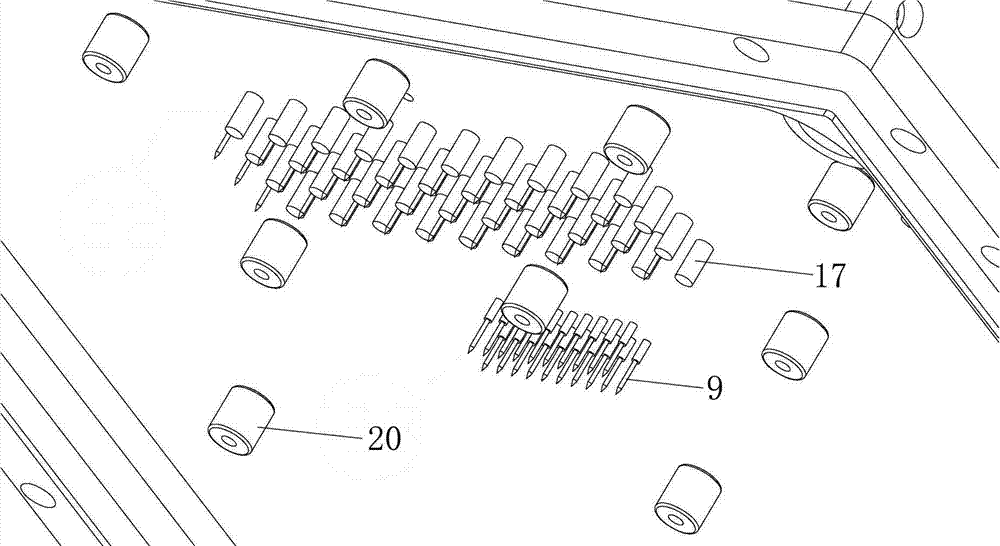

[0022] refer to Figure 1 to Figure 4 , a fixture suitable for a circuit board testing machine includes: a lower plate 1, an upper platen 3 connected to the lower plate 1 through a rotating shaft (not shown), and two ends of the air pressure fixed on the lower plate 1 and the upper platen 3 respectively spring 4. The above-mentioned structure will be described in detail below with the fixture applicable to the Agilent HP3070 test machine as an example. However, those skilled in the art should understand that the embodiments are more specific and detailed, but do not represent limitations to the present invention. The technical solution is subject to what is described in the claims.

[0023] First introduce the lower board 1.

[0024] The lower plate 1 is rectangular, and in this embodiment, its length is 508.98 mm and its width is 556....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com