Micro-motor of breaker applicable for multiple voltage ranges

A micro-motor, voltage range technology, applied in the direction of circuits, resistors, electric components, etc., can solve the problems of easy disconnection of winding wires, difficult control of motor commutation sparks, damage, etc., to reduce utilization rate and simplify winding Easy effect with manufacturing process and quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

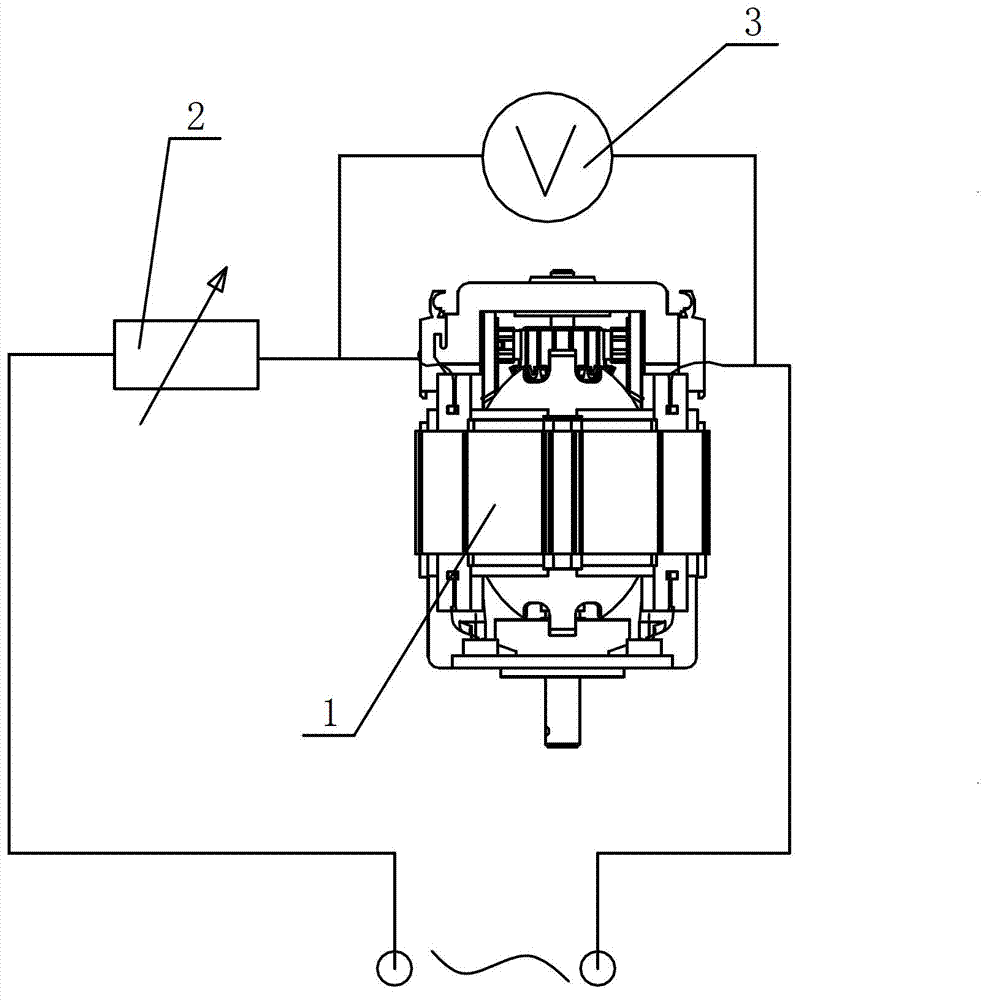

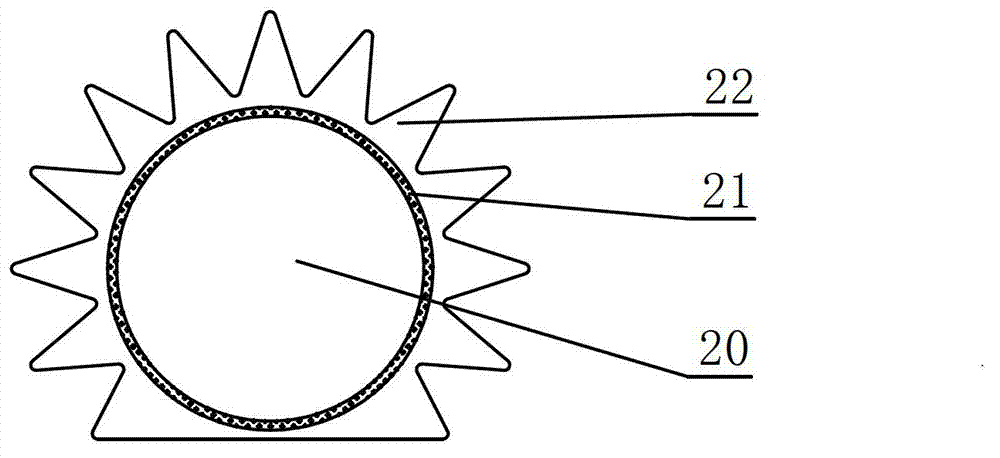

[0017] see figure 1 and figure 2 As shown, in this embodiment, a circuit breaker miniature motor for various voltage ranges includes a motor body 1, a variable resistor 2 connected in series with the motor body 1, and a voltmeter 3 connected in parallel with the motor body 1 , the variable resistor 2 includes a variable resistor 20, the variable resistor 20 is bonded with a heat dissipation component 22 through a thermally conductive insulating epoxy adhesive 21, and the heat dissipation component 22 is coated on the variable resistor 20 in the form of Serrated cooling fins.

[0018] The above-mentioned miniature motor used in the circuit breaker uses the principle of voltage division of resistors in a series circuit, and the variable resistor 2 is connected in series to the circuit of the motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com