Dual alternating current chopper speed regulation of wound-rotor asynchronous motor

An asynchronous motor and AC chopping technology, which is applied in the direction of AC motor control, electrical components, control systems, etc., can solve problems such as inability to guarantee the safety of components, insufficient power factor, and large inrush current

Inactive Publication Date: 2012-11-14

王小兵

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] Even this choice cannot guarantee the safety of the components, because the inrush current of ordinary motors when they are directly started, blocked and "overturned" by the inverter is much greater than this

Therefore, there is a potential danger of thermal breakdown of components due to overcurrent protection failure

[0015] Due to the influence of the commutation voltage drop of the rectifier bridge and the limitation of the minimum inverter angle of the inverter, the power factor of this scheme is not high enough, and the minimum speed is not low enough; The process is accompanied by energy loss, and its energy-saving effect is not satisfactory

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0083] 1. This scheme can replace the current speed regulation schemes of various winding asynchronous motors.

[0084] 2. This scheme can be used for stepless speed regulation of large speed ratio for wound-type asynchronous motors of various voltage levels and various power levels.

[0085] 3. This scheme is especially suitable for use in occasions where impact loads often occur.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

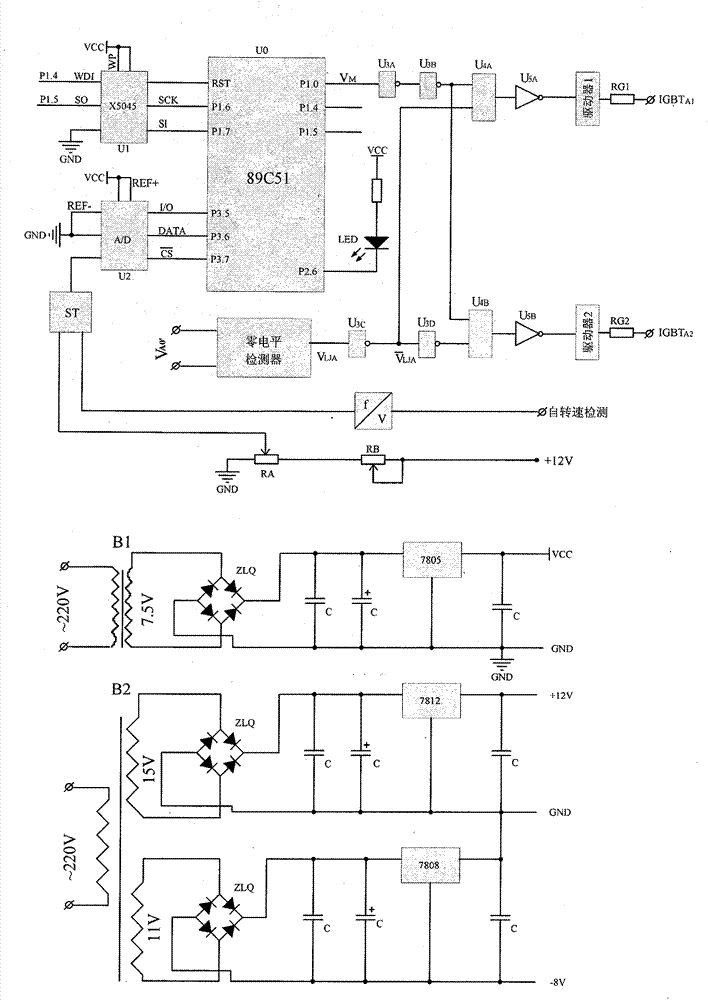

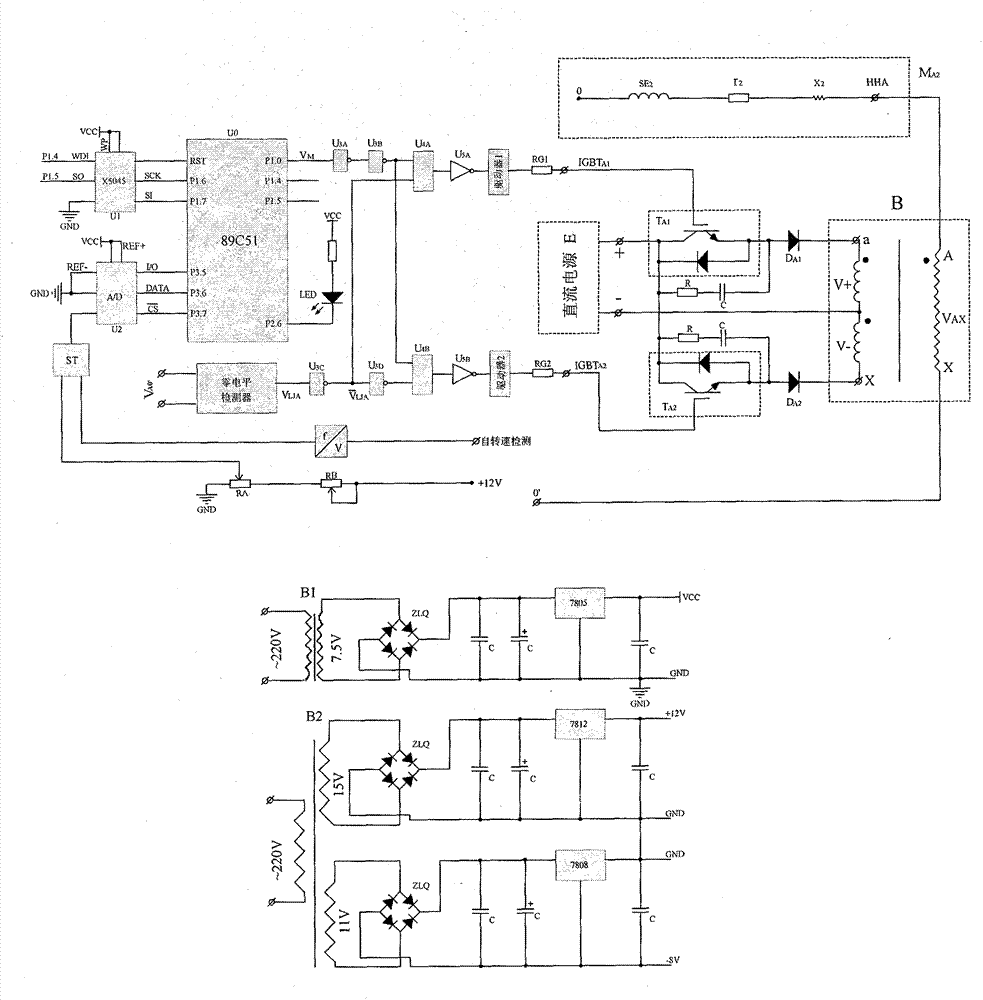

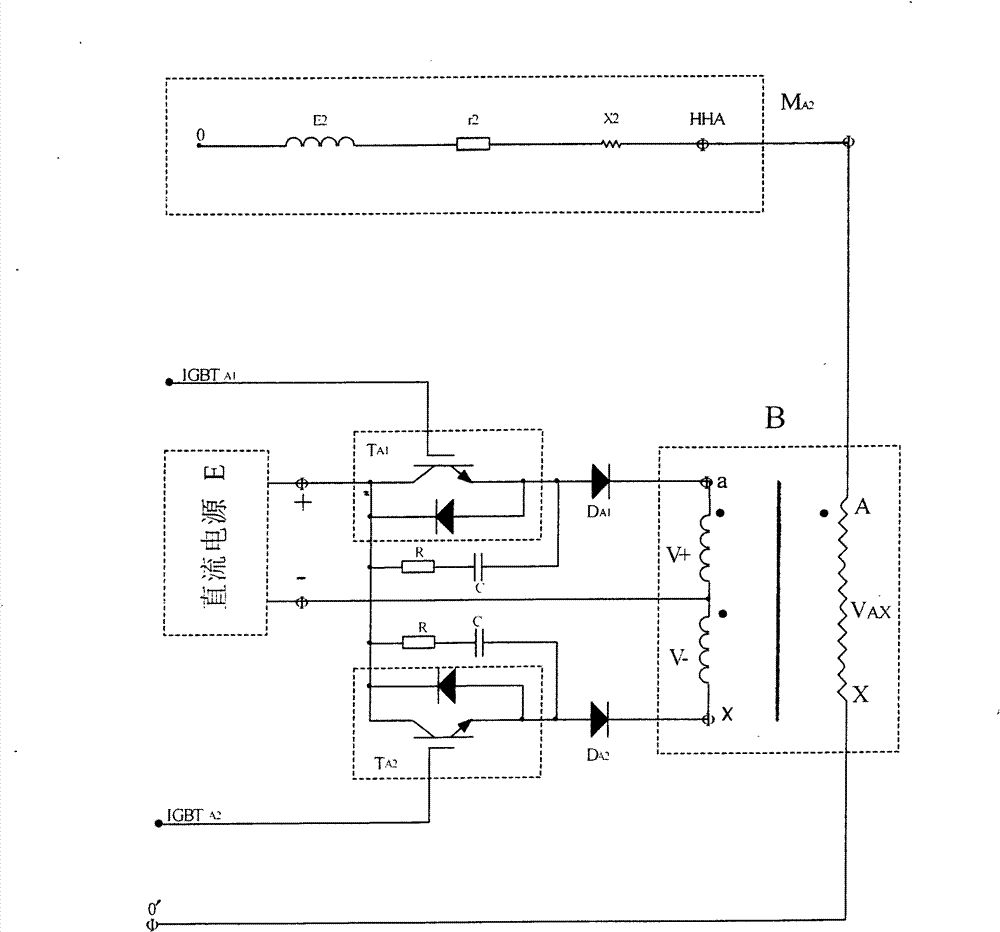

The invention relates to dual alternating current chopper speed regulation of a wound-rotor asynchronous motor, which belongs to the technical field of electrical engineering. Rotor resistance speed regulation has the disadvantages of large energy loss and difficulty in realization of stepless speed regulation. A speed regulating scheme containing an inverter link has the disadvantages of complex system, low power factor and narrow speed regulating range, and is not suitable for low-power motors. A scheme that a main rotor loop contains a direct current chopper link has the disadvantages of large current capacity and poor reliability of a self turn-off element which is used. Aiming at the problems, the invention provides a new technical scheme, i.e. a dual alternating current chopper is used for chopping slip voltage, so as to change an equivalent value of the slip voltage to realize the stepless speed regulation and achieve the effects of more significant energy saving effect, higher power factor, better starting performance and mechanical properties, wider speed regulating range, small current capacity of the self turn-off element and simple and reliable system. The scheme can be used for large speed ratio stepless speed regulation of the wound-rotor asynchronous motor in various sizes and is especially suitable for the situation that impact load often occurs.

Description

1. Technical field [0001] Electrotechnical 2. Background technology [0002] Compared with the squirrel cage asynchronous motor with the same capacity, the wound asynchronous motor can obtain smaller starting current and larger starting torque, and has the characteristic of adjustable speed. Therefore, although its speed regulation method is not satisfactory, it is still widely used in many sectors of the national economy. [0003] At present, the speed regulation methods of domestic wound asynchronous motors are as follows: [0004] 1. Rotor series resistance speed regulation This speed regulation method is based on the proportional relationship between the critical slip and the reduced resistance of the rotor. During the speed regulation process, the slip energy is consumed on the rotor resistance, so the efficiency is low and the mechanical characteristics are soft. Because it is inconvenient to change the series resistance value through multiple switching, it is diffi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02P25/02H02P25/28

Inventor 王小兵

Owner 王小兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com