Offset calibration and precision hysteresis for a rail-rail comparator with large dynamic range

A rail-to-rail and offset calibration technology, which is applied to amplifiers, amplifiers, and differential amplifiers with semiconductor devices/discharge tubes, and can solve problems such as complicating comparators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Referring now to the drawings, details of certain exemplary embodiments are schematically illustrated. Like elements in the drawings will be represented by the same numerals, and similar elements will be represented by the same numerals with different lowercase letter suffixes.

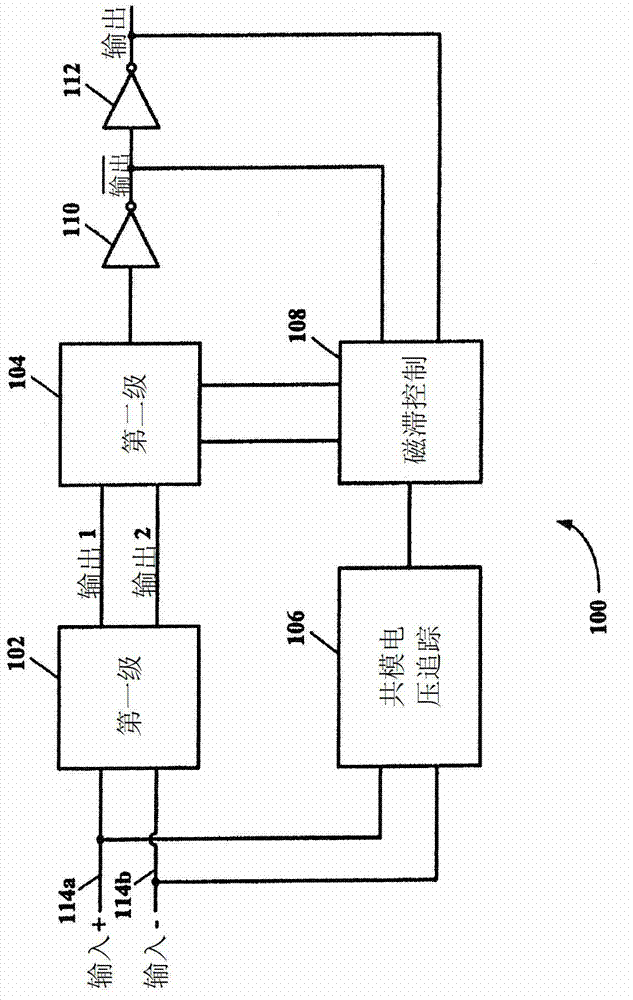

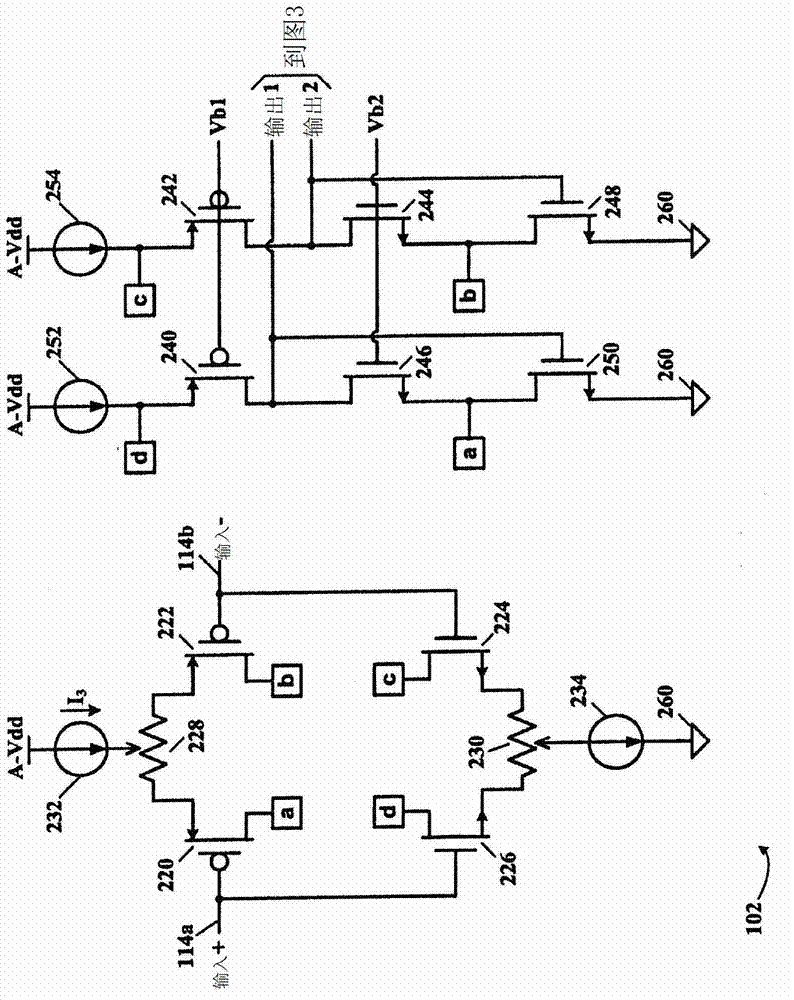

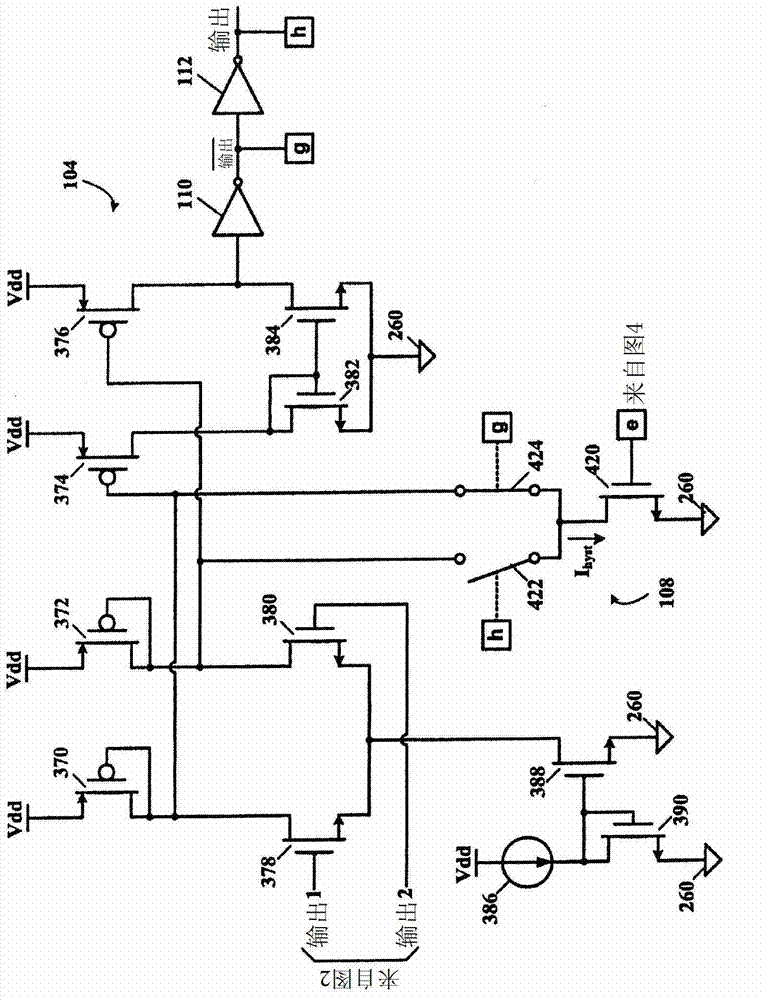

[0015] refer to figure 1 , which depicts a schematic block diagram of a two-stage rail-to-rail comparator according to certain exemplary embodiments of the present invention. A two-stage rail-to-rail comparator generally indicated by numeral 100 includes: a first stage 102 , a second stage 104 , a common mode voltage tracking circuit 106 and a hysteresis control 108 . The first stage 102 has a differential input 114 connected to a differential input pair feeding current to a diode-connected load ( figure 2 ). Second stage 104 receives the differential output signal (Output 1 and Output 2 ) from first stage 102 and amplifies this output signal sufficiently to drive inverting gate 110 , which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com