Self walking type garlic combine harvester

A combine harvester and self-propelled technology, which is applied in the direction of digging harvesters, harvesters, excavators, etc., can solve the problems of incapable of batch production and large-scale promotion and application, unreliable quality, and operation congestion, so as to reduce garlic Damage, reduce machine energy consumption, reduce the effect of walking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

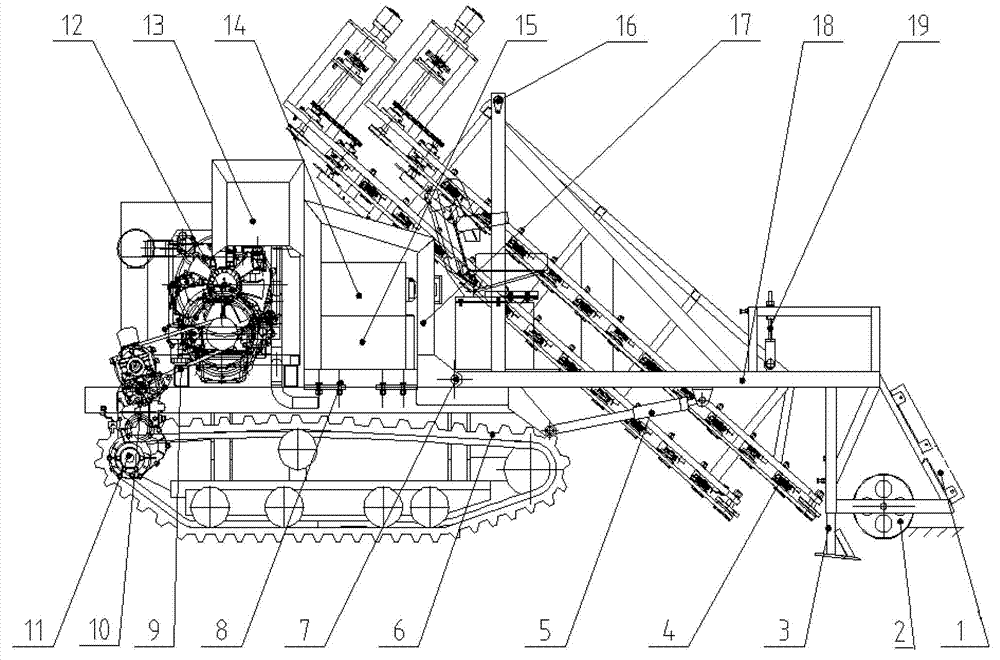

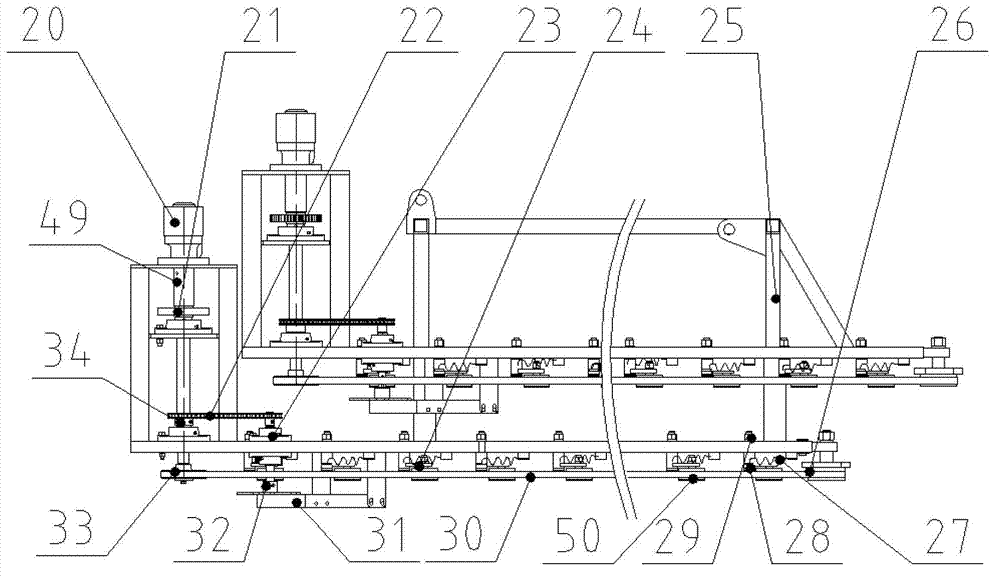

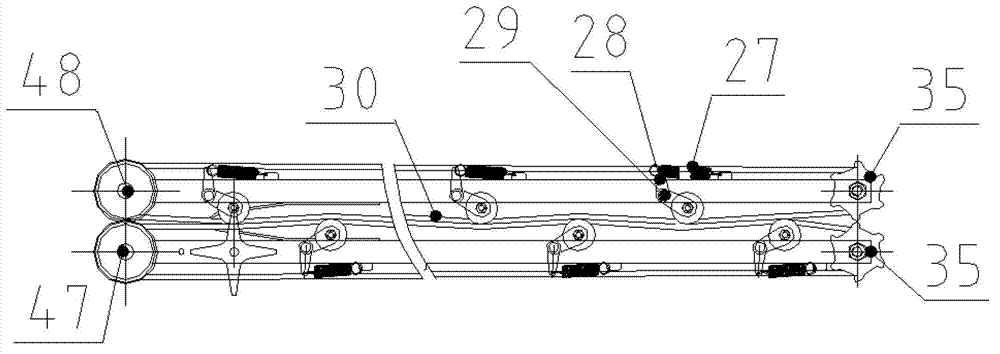

[0031] Self-propelled garlic combine harvester, combined with picture to Figure 6 , comprising a walking chassis 6, an engine 12, an underframe 17, a lifting frame 18, a clamping device 4, a garlic seedling laying groove 13, a garlic conveying groove 14, and a garlic collecting box 15, and the walking chassis 6 is provided with a chassis drive bridge 11 , the underframe 17 is connected with the walking chassis 6, the rear end of the lifting frame 18 is connected with the bottom frame 17, the front end is hingedly connected with the lifting cylinder 5, the lifting cylinder 5 rotates around the lifting frame shaft 7, and the lower part of the front end of the lifting frame 18 is arranged Excavation device 3 is arranged, and the front portion of excavation device 3 is provided with membrane breaking knife 2, and the front portion of membrane breaking knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com