Device for preventing coolant material of an X-ray unit from evaporating when being overheated

An evaporation device and coolant technology, which is applied in medical science, instruments for radiological diagnosis, diagnosis, etc., can solve the problems of reducing the effective heat transfer area, large heat generation, overheating of X-ray tubes, etc., and achieves good cooling effect, The effect of prolonging the service life and suppressing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

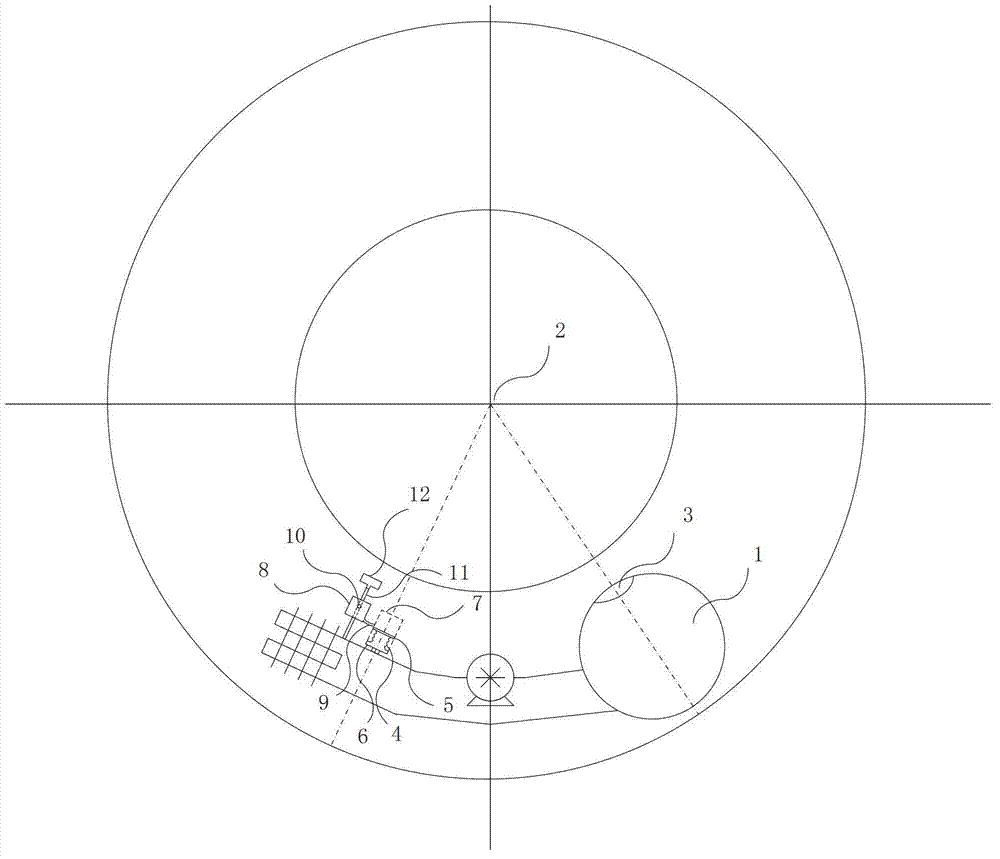

[0019] The boiling point of liquid coolant is determined by the static pressure of the liquid, the lower the static pressure, the lower the boiling point and the easier the liquid evaporates. When the X-ray machine is working, the X-ray tube rotates around the system axis 2, and the rotational centrifugal force acceleration is much greater than the gravitational acceleration, so the hydrostatic pressure depends on the rotational centrifugal force. The centrifugal force at a certain point in the rotating body is proportional to the distance between this point and the center of rotation. Therefore, the static pressure in the output window area 3, which is closest to the system axis and under strong thermal load, is the smallest. In order to suppress the tendency of air bubbl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com