Skimming device for bridge-type sand sucker

A sand suction machine and bridge-type technology, applied in the feeding/discharging device of the sedimentation tank, chemical instruments and methods, separation methods, etc. To solve problems such as surface changes, to achieve the effect of good automation, reasonable structure and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

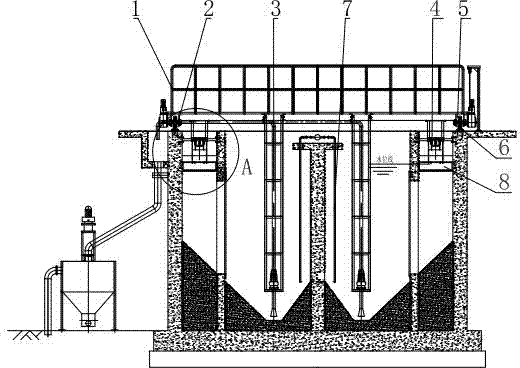

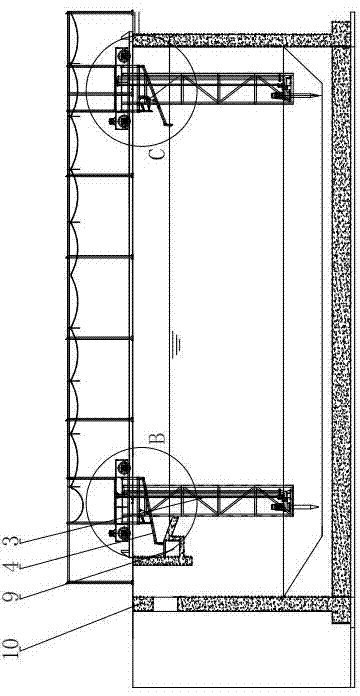

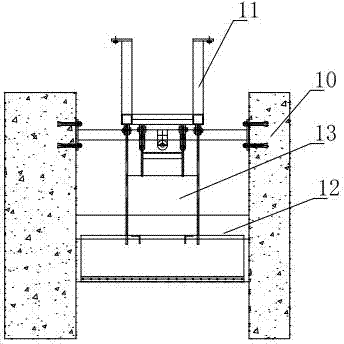

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0017] Such as image 3 , Figure 4 As shown, the skimming device 4 of the present invention adopts a square steel pipe to make the upper bracket 11 of the skimming rake 12, which is fixed on both sides of the working bridge 1 of the bridge sand suction machine by bolts; the lower part of the upper bracket 11, one end passes through The pin shaft is hinged with a skimmer rake 12, and the other end is hinged with a hook plate 13. The bottom surface of the hook plate 13 is an oblique angle, and a triangular cut 17 is arranged above the oblique angle. correspond. At the bottom of the upper bracket 11, a tension spring 14 is provided to pull and tighten the hook plate 13, and a suspension chain 15 is provided to suspend the scum rake 12. A scum collecting bucket 9 is arranged at the skimming end of the sedimentation tank 10, and a fixed L-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com