Water internally-distributed type flexible dust collecting electrode device

A technology of water distribution device and dust collecting pole, which is applied in the field of flue gas pollution control, can solve the problems of affecting dust collection efficiency of dust collecting pole, affecting dust removal efficiency, incomplete dust cleaning, etc., and achieves automatic and efficient dust removal and efficient collection , the effect of equipment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

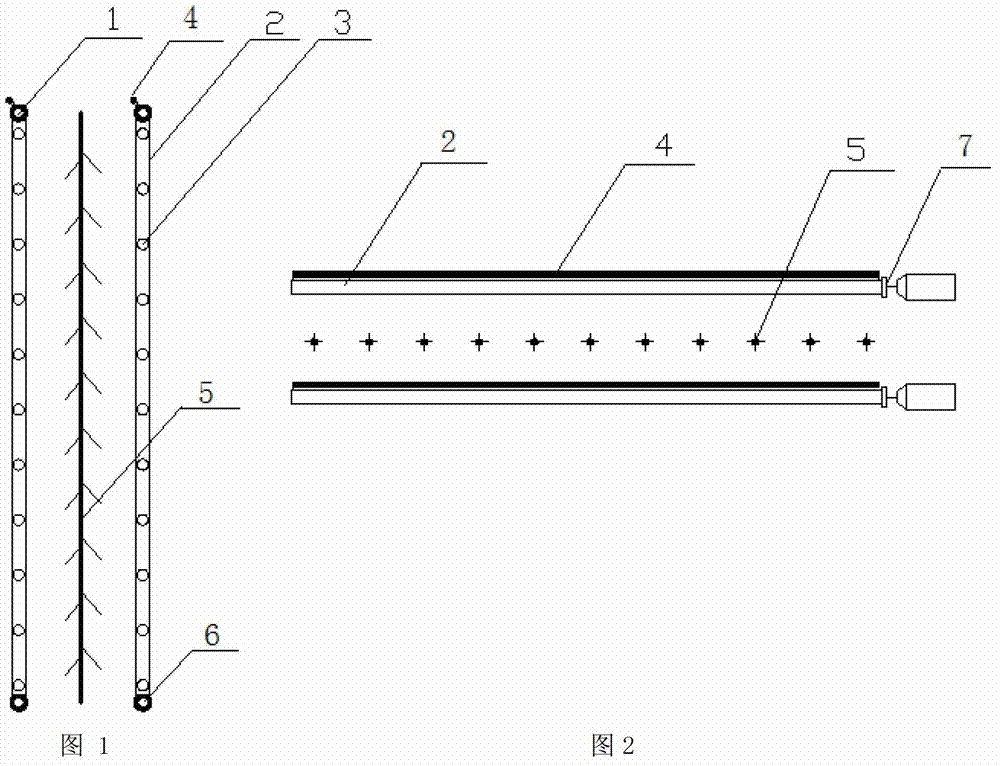

[0031] Example 1: Such as figure 1 , 2 As shown, the inner water-distributed flexible dust collecting device includes a driving shaft 1, a driven shaft 6 and a flexible dust collecting electrode 2. The flexible dust collecting electrode 2 is wound on the driving shaft 1 and the driven shaft 6, and the driving shaft A number of water distribution devices 3 are arranged between the flexible dust collecting electrode 2 between 1 and the driven shaft 6, the driving shaft 1 is connected with a power device, and an electrode 5 is arranged on at least one side of the flexible dust collecting electrode 2. The flexible dust collecting pole 2 is provided with at least one dust cleaning device 4 which is in contact with its outer surface. At least one end of the driving shaft 1 and the driven shaft 6 is provided with a limiting device 7. The limit device 7 is a limit block or a limit protrusion. The flexible dust collecting electrode 2 is a plate-shaped body composed of a flexible fabric...

Embodiment 2

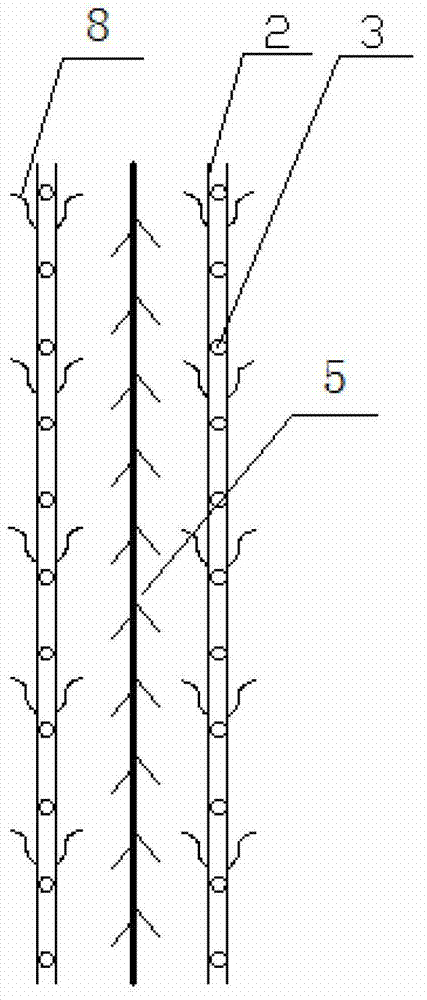

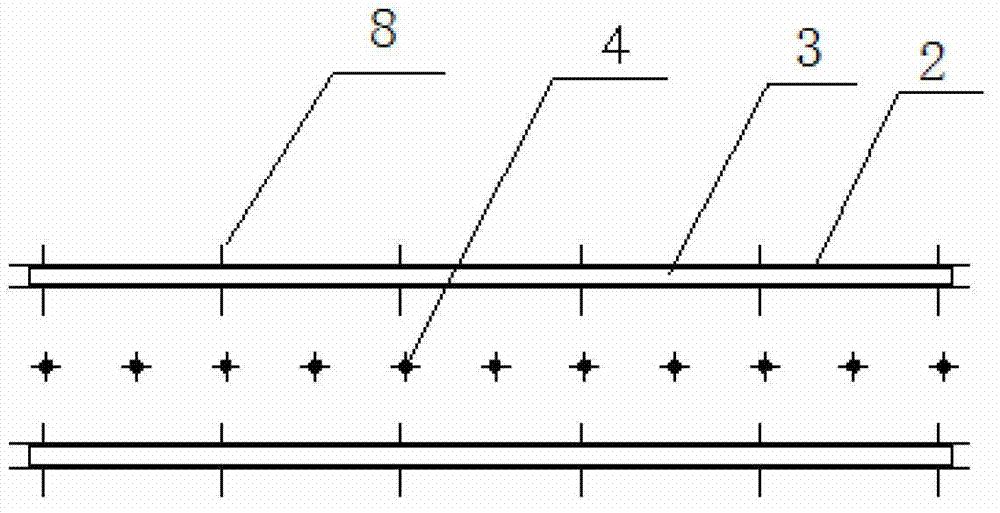

[0033] Example 2: Such as image 3 , 4 As shown, the inner water-distributing flexible dust collecting electrode device includes a pair of flexible dust collecting electrodes 2 arranged in parallel, a water distributing device 3 is arranged between the pair of flexible dust collecting electrodes 2, and the flexible dust collecting electrode 2 is implanted Into the conductivity testing device 8, at least one side of the outside of the flexible dust collecting electrode 2 is provided with an electrode 5. The distance between a pair of flexible dust collecting electrodes 2 is between 20-80mm. The flexible dust collecting electrode 2 is a plate-shaped body composed of a flexible fabric. The water distribution device 3 is a steel pipe with small holes or grooves. The angle between the small hole or groove on the steel pipe and the horizontal direction is greater than 0° and less than 90°.

[0034] As the voltage rises, the tip of the electrode 5 discharges to ionize the air and prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com