Ferrule type threading straight coupling

A straight-through joint and ferrule-type technology, which is applied in the direction of pipe/pipe joint/pipe fitting, passing element, sealing surface connection, etc., can solve the problems of unsatisfactory sealing effect and insufficient connection, and achieve good sealing and repeatability , reliable connection, safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

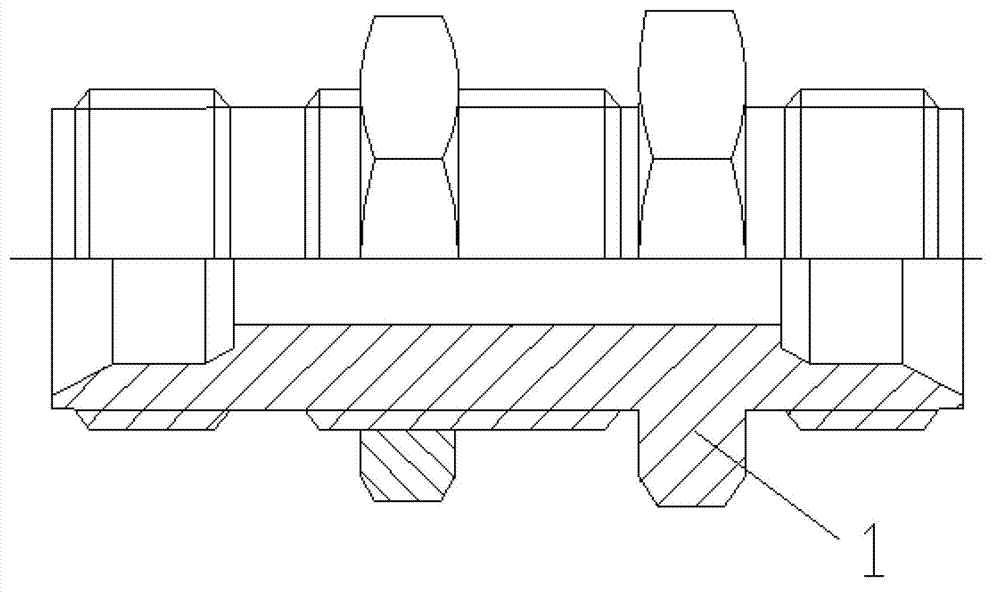

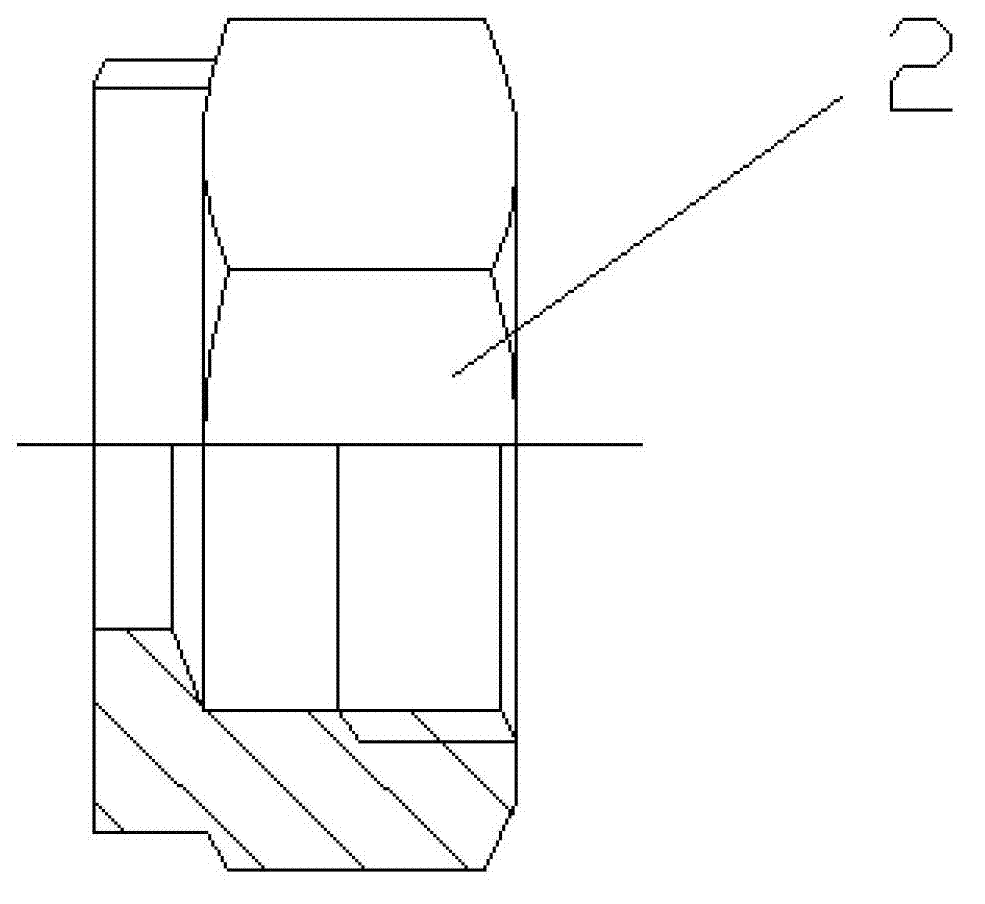

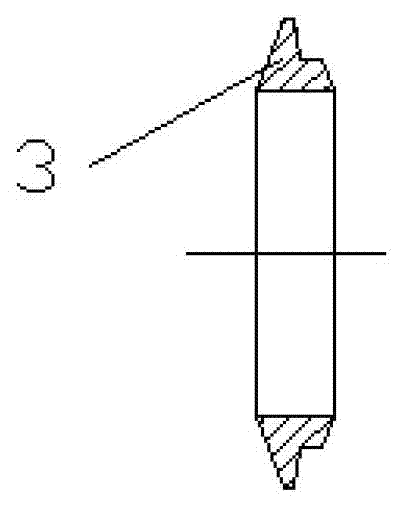

[0017] Such as Figure 1 to Figure 5 As shown, the present invention includes a joint body 1, two nuts 2 and two ferrules respectively located at both ends of the joint body 1, and the ferrules are split ferrules, including sub-ferrules A 3 and sub-ferrules B 4 . The sub-ferrule A 3 is a ring structure, and its cross section is an italic L-shaped structure. The ferrule B 4 is a ring structure, one end of its cross section matches the opening end of the L-shaped structure of the ferrule A 3 , and the other end is an inclined plane.

[0018] During use, take a steel pipe of appropriate length, remove the burrs at the port, and make the end face of the steel pipe perpendicular to the axis. Put the nut 2, ferrule A 3 and ferrule B 4 on the steel pipe. Apply lubricating oil to the thread of the joint body 1 and the ferrule, insert the steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com