Compensation system with repeated error weighted stacking in numerical control system

An error compensation and compensation system technology, applied in the fields of precision control and precision machining, can solve the problems of positioning accuracy not meeting the requirements of design indicators, long working time, inability to adjust or add error compensation, etc., to improve repeated positioning accuracy. 、Convenient debugging of machine tool accuracy, to achieve the effect of compensation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

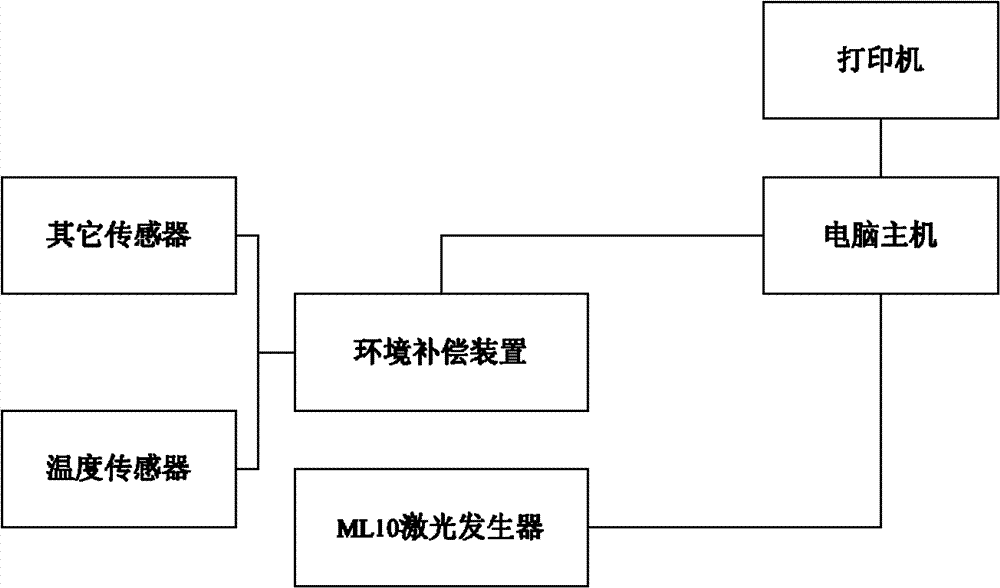

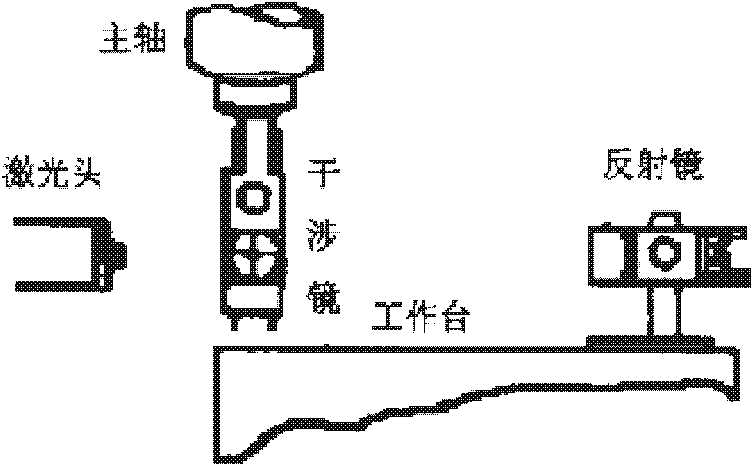

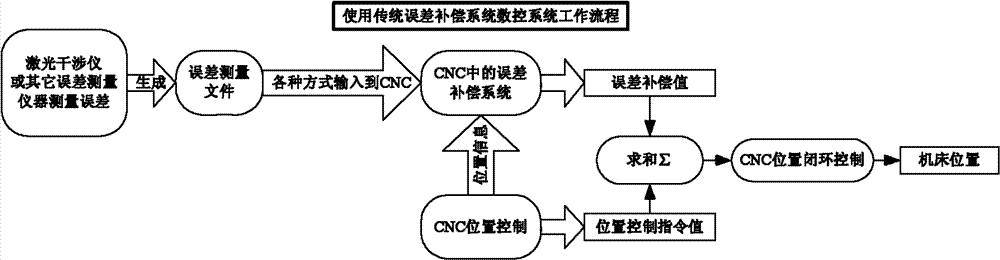

[0036] 1. Technical solution

[0037]The error compensation value is essentially a function of the command position, and its correction value changes continuously with the actual moving position of the lead screw. Compared with the traditional error compensation, the present invention has the advantage that it can continue to measure the error on the basis of the error compensation that has already taken effect, and then add the measured new error value to the numerical control system, and superimpose the new error error compensation value on the On top of the original error compensation, the positioning accuracy of the CNC machine tool is continuously improved, so that the accuracy of the CNC machine tool meets the design index requirements. At the same time, it is also possible to set the compensation weight for a certain error compensation item to provide users with a more flexible error compensation debugging function and make the man-machine interface more flexible and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com