Ice removing mechanism of ice removing robot for overhead cable

A kind of overhead cable and robot technology, which is applied in the direction of overhead installation, cable installation, manipulator, etc. It can solve the problems of failure to show, the robot should not be too large, and damage the cable, etc., and achieve the effect of simple structure and good deicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

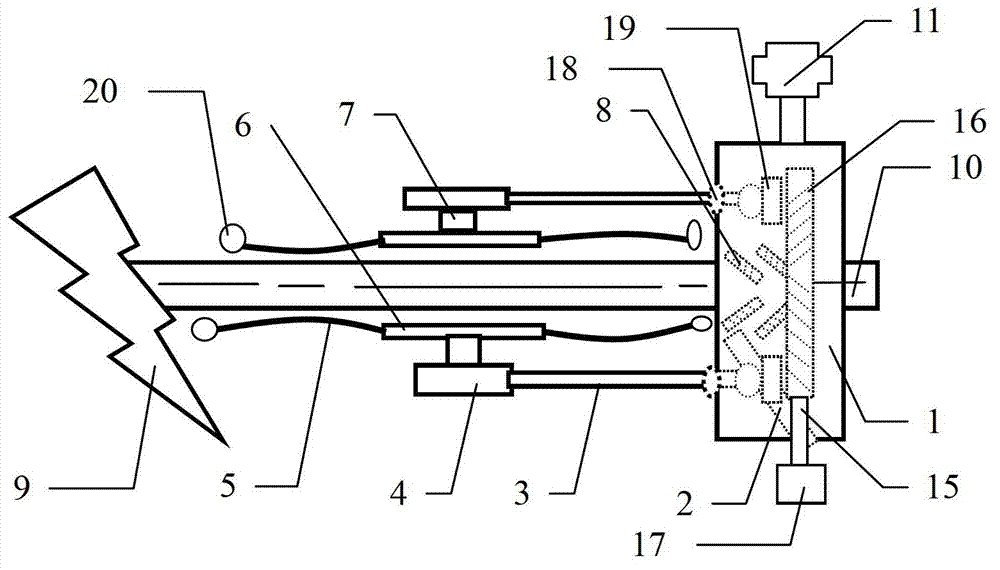

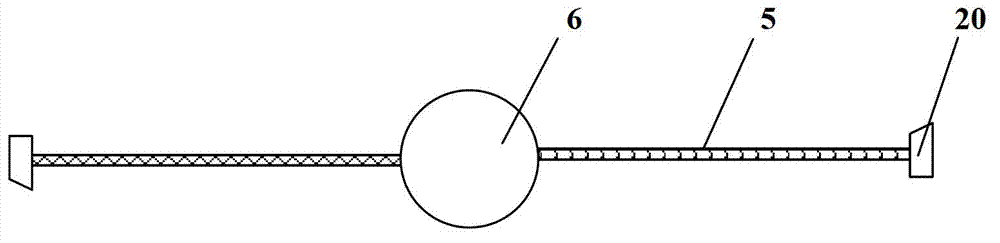

[0025] The deicing mechanism of the overhead cable deicing robot of the present invention is a percussion flexible deicing mechanism, which is driven by the overhead cable deicing robot and installed on the front end of the overhead cable deicing robot when in use.

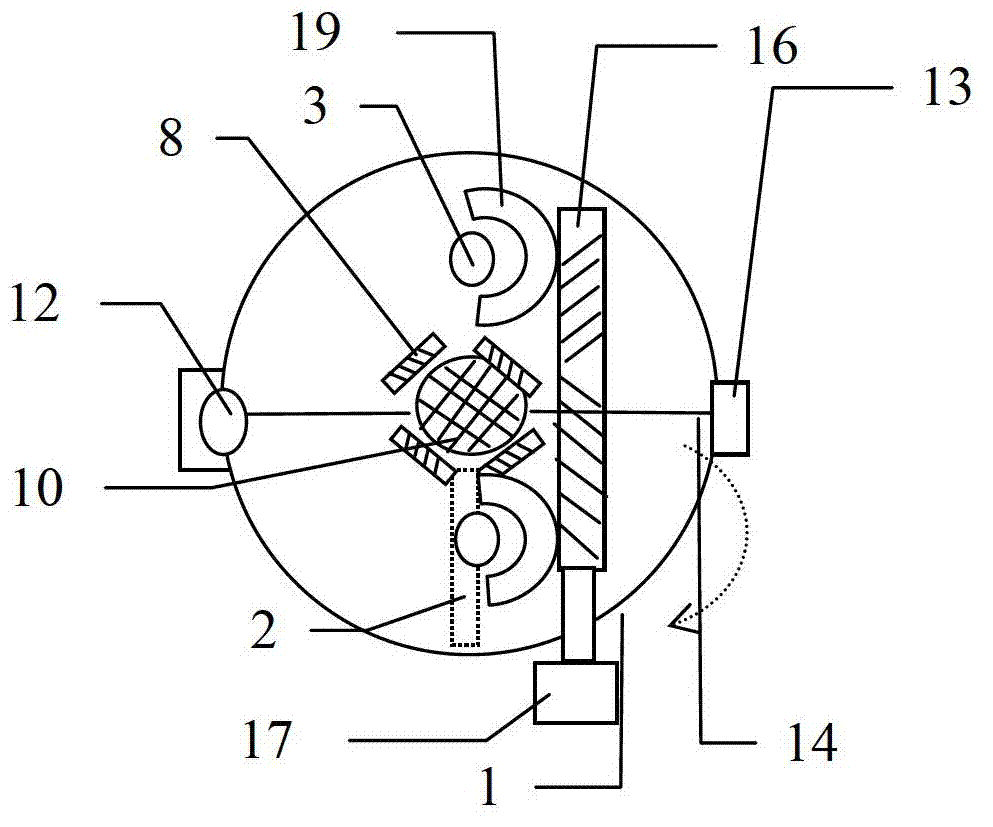

[0026] The inventive point of the deicing mechanism of the overhead cable deicing robot of the present invention lies in the novel design of the structure of the deicing mechanism, see figure 1 , figure 2 As shown, the deicing mechanism of the overhead cable deicing robot specifically includes:

[0027] A mechanism body 1 has an inner chamber; the mechanism body 1 can be composed of an upper part and a lower part, and is electrically controlled to open and close through an electromagnetic fixing device and a base driving motor respectively located at the upper part and the lower part during installation. In this embodiment, the lower base driving motor 12 is installed behind the upper side of the mechanism body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com