Device for controlling a fluid flow

A technology for controlling fluids and manipulating devices, which is applied in packaging, liquid materials, transportation and packaging, etc. It can solve the problems of affecting the direction of overflow, the influence of geometry that cannot overflow, and the phenomenon of product spraying that cannot be reliably avoided, so as to reduce foam. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

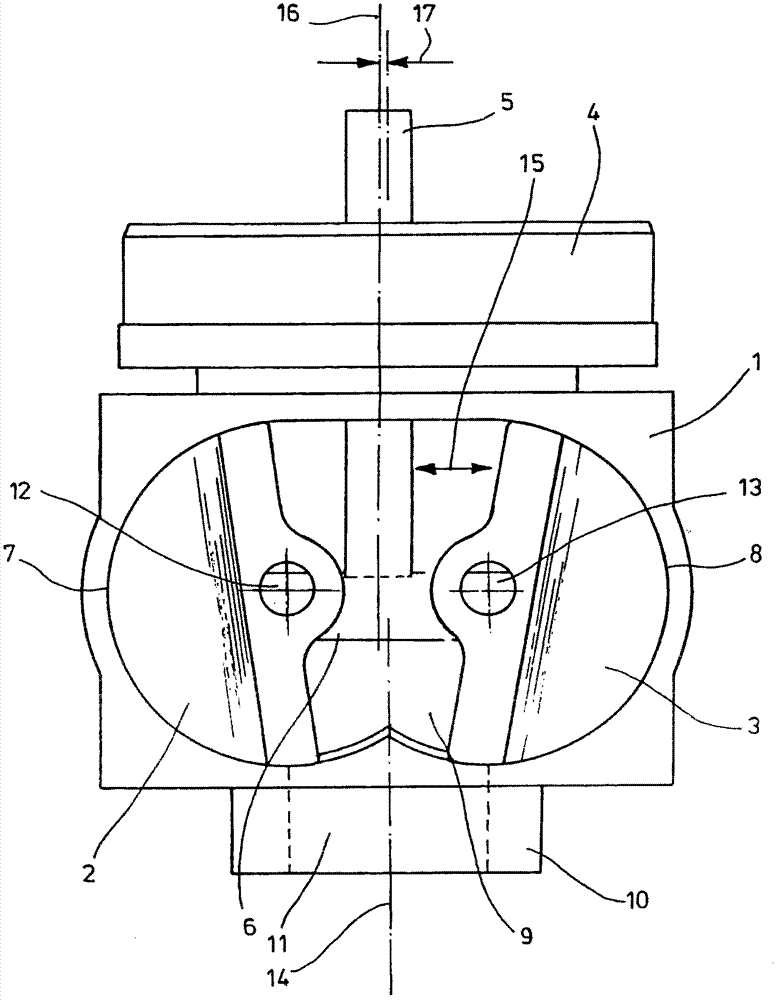

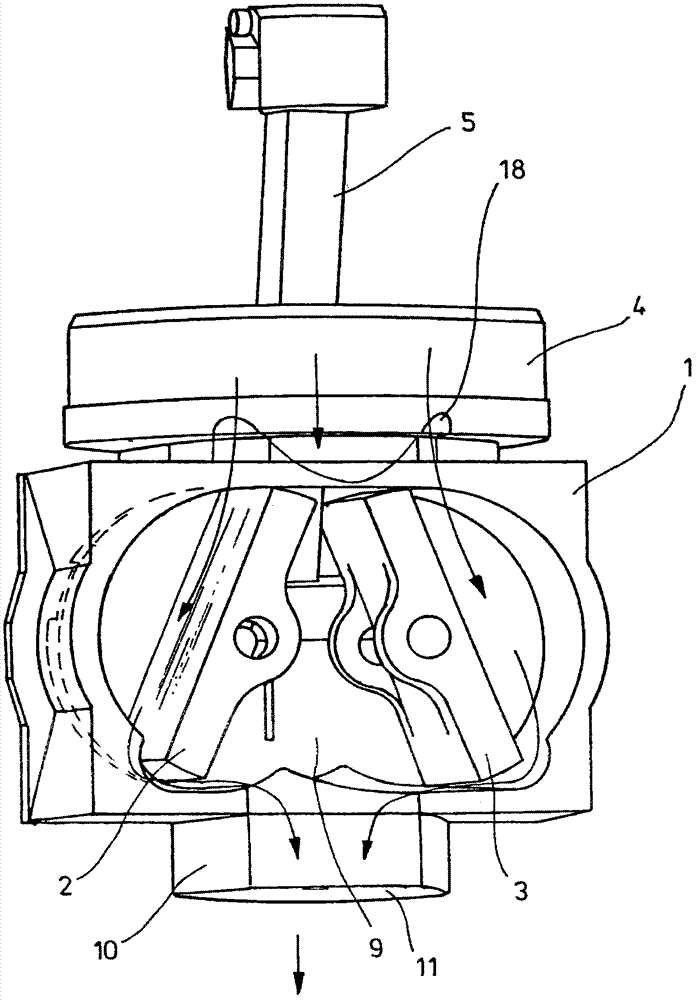

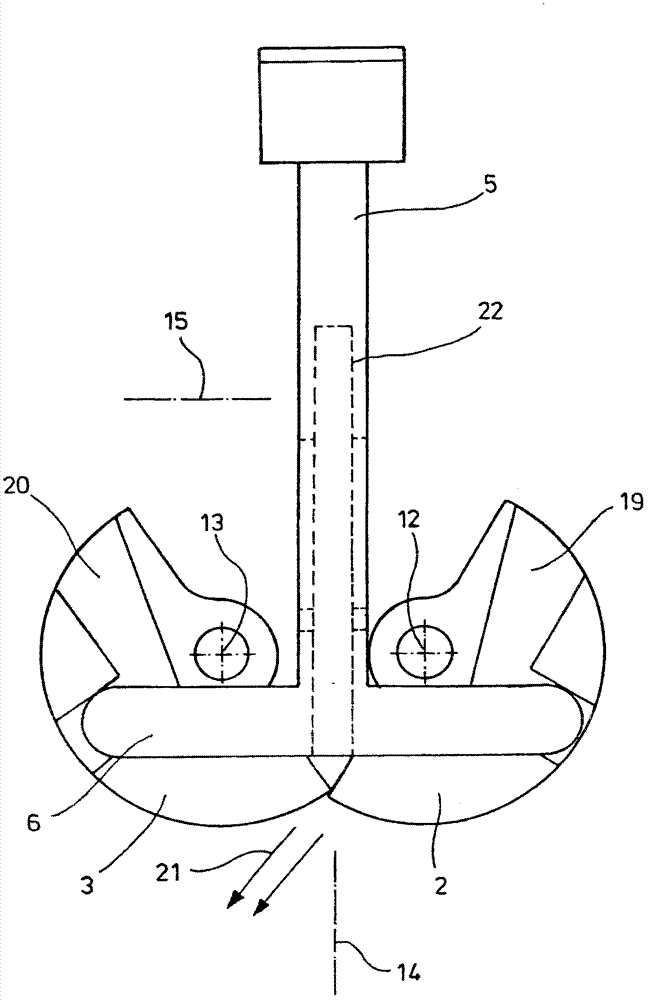

[0025] in accordance with figure 1 In the embodiment shown, two valve elements 2 , 3 are arranged in the housing 1 . The housing 1 has a cover 4 through which an actuating element 5 can be guided. In the exemplary embodiment shown, the actuating element 5 is configured in the form of a rod and is provided with a transverse web 6 in the region of its end facing the valve elements 2 , 3 . The transverse web 6 transmits the movement of the actuating element 5 to the valve elements 2 , 3 and predetermines its positioning relative to the housing 1 .

[0026] In particular, it is contemplated that the actuating element 5 can be arranged at least in regions or also completely inside the packing and thus protect it from contact with the external environment. Such an arrangement is particularly advantageous for sterile or aseptic filling processes, since contamination by germs, molds or microorganisms can thereby be avoided. The actuating element 5 arranged completely inside the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com