Apparatus and method for treating products

A technology for processing products and equipment, applied to the application of piezoelectric elements, processing products that are continuously supplied to equipment, and capable of solving problems such as the impossibility of eliminating unit offsets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the drawings described below, the same reference numerals denote the same or similar elements.

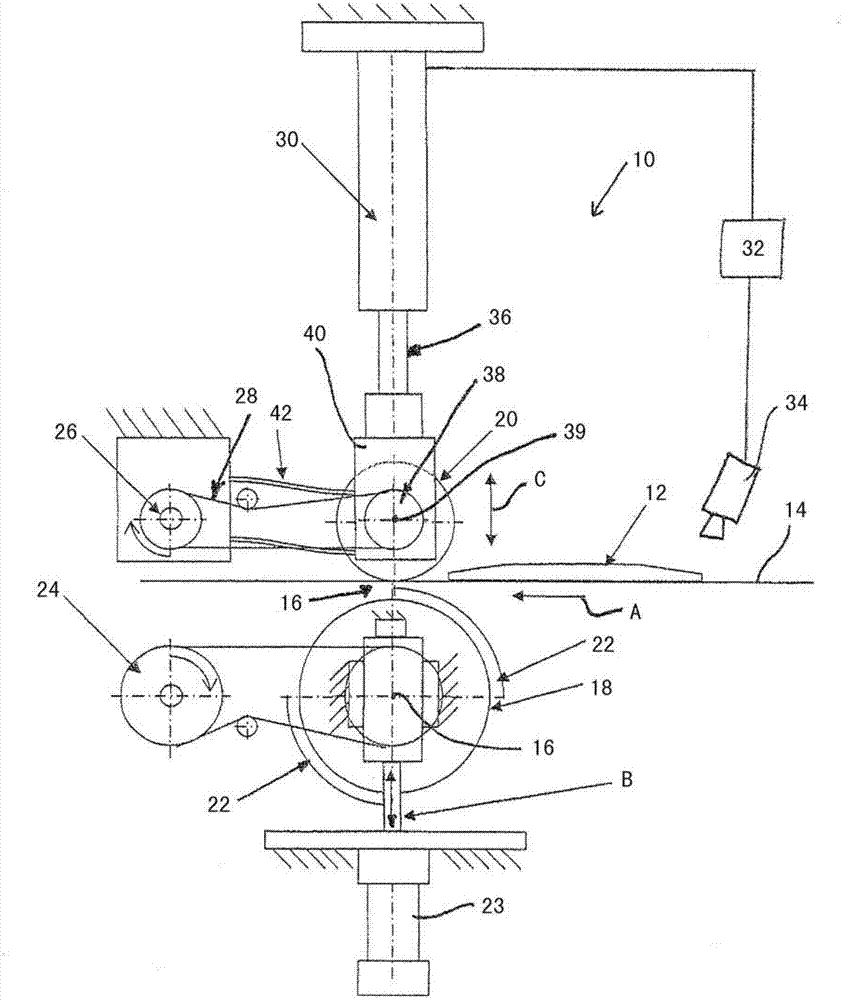

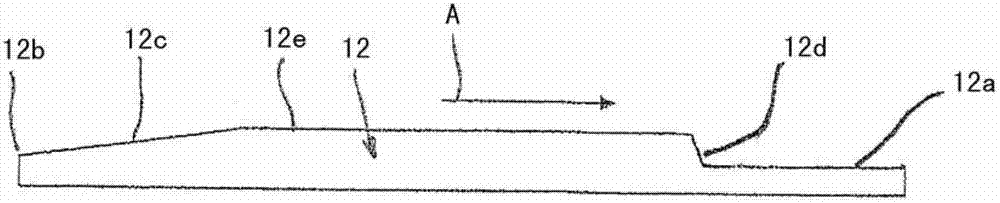

[0034] figure 1 The apparatus of the invention is shown schematically for the treatment of products which are continuously supplied to the apparatus 10 . The individual products 12 are placed on conveyor means 14 which may be of any conventional type and which conveys and feeds the products 12 through the apparatus.

[0035] The product is processed in the gap 16 formed between the processing roll 18 and the backup roll 20 . The processing roll 18 is an embossing roll in the particular example shown and schematically shows patterned ridges 22 on the outer peripheral surface of the roll 18 . The embossing roll rotates about an axis of rotation 19 and is driven by a suitable conventional drive 24 .

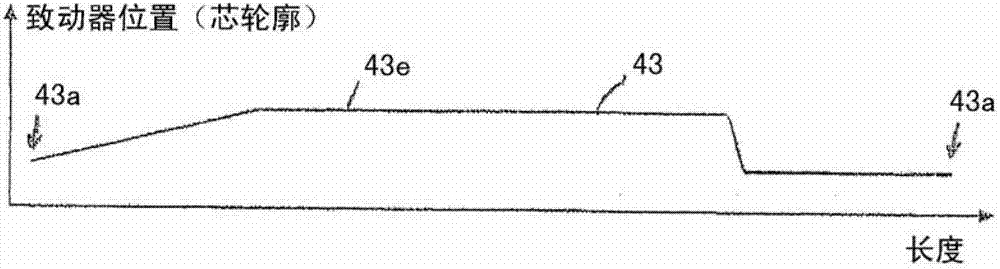

[0036] The vertical position of the processing roller 18 can be roughly adjusted in the direction indicated by arrow B. This coarse adjustment can be achieved through the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com