Device for generating gas-nanoparticle two-phase uniform fluid

A technology of nano-particles and generating devices, applied in the direction of gas/steam and solid mixing, fluid mixer, dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

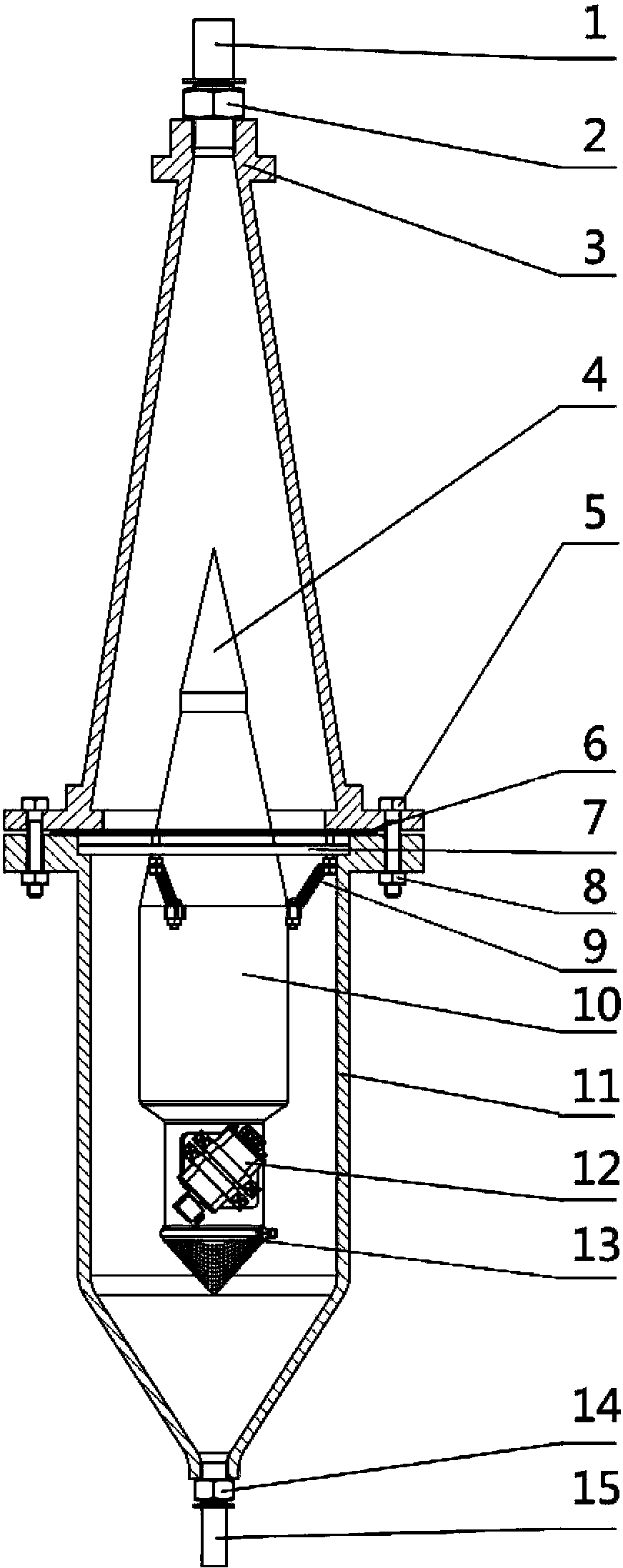

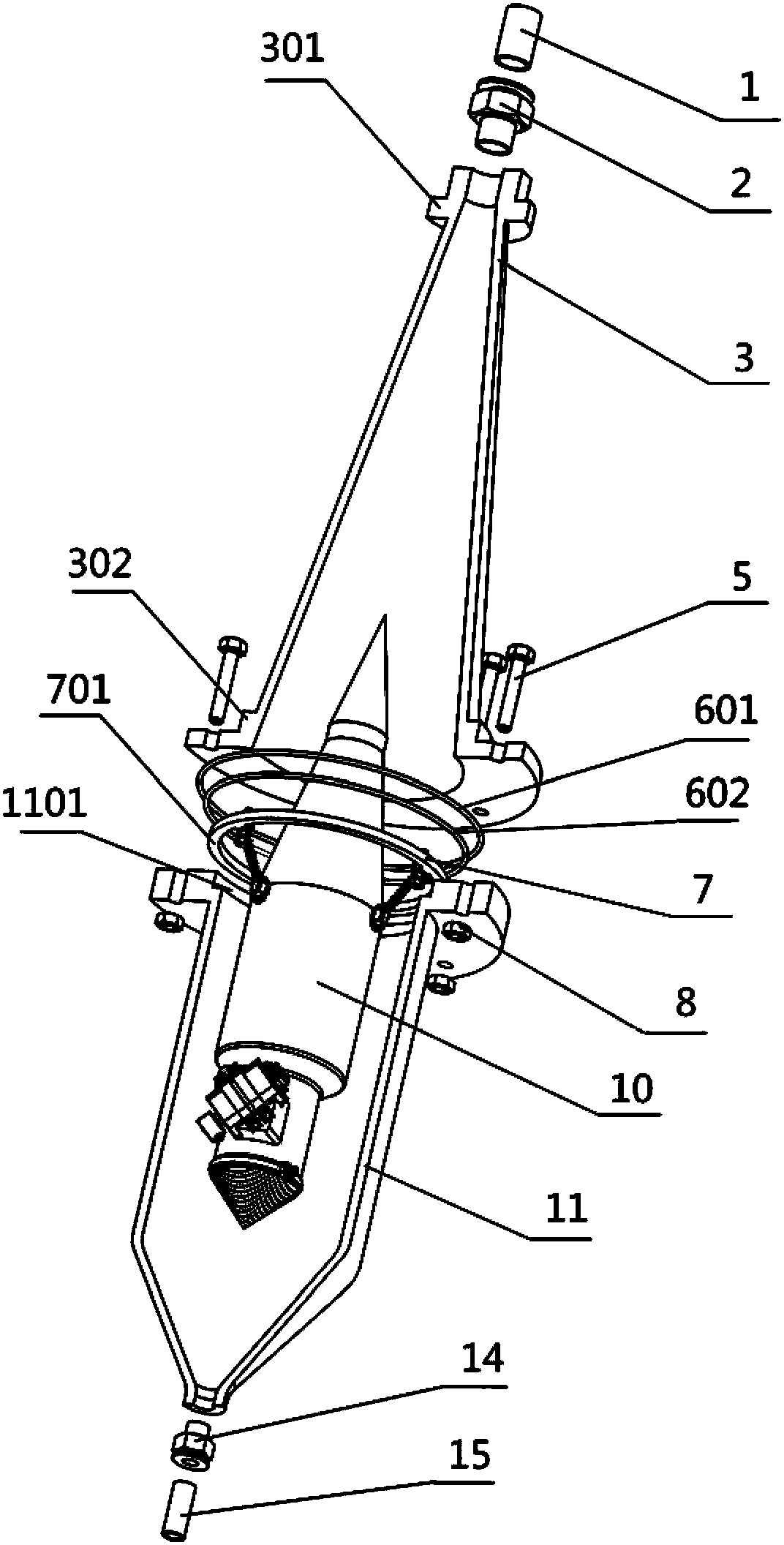

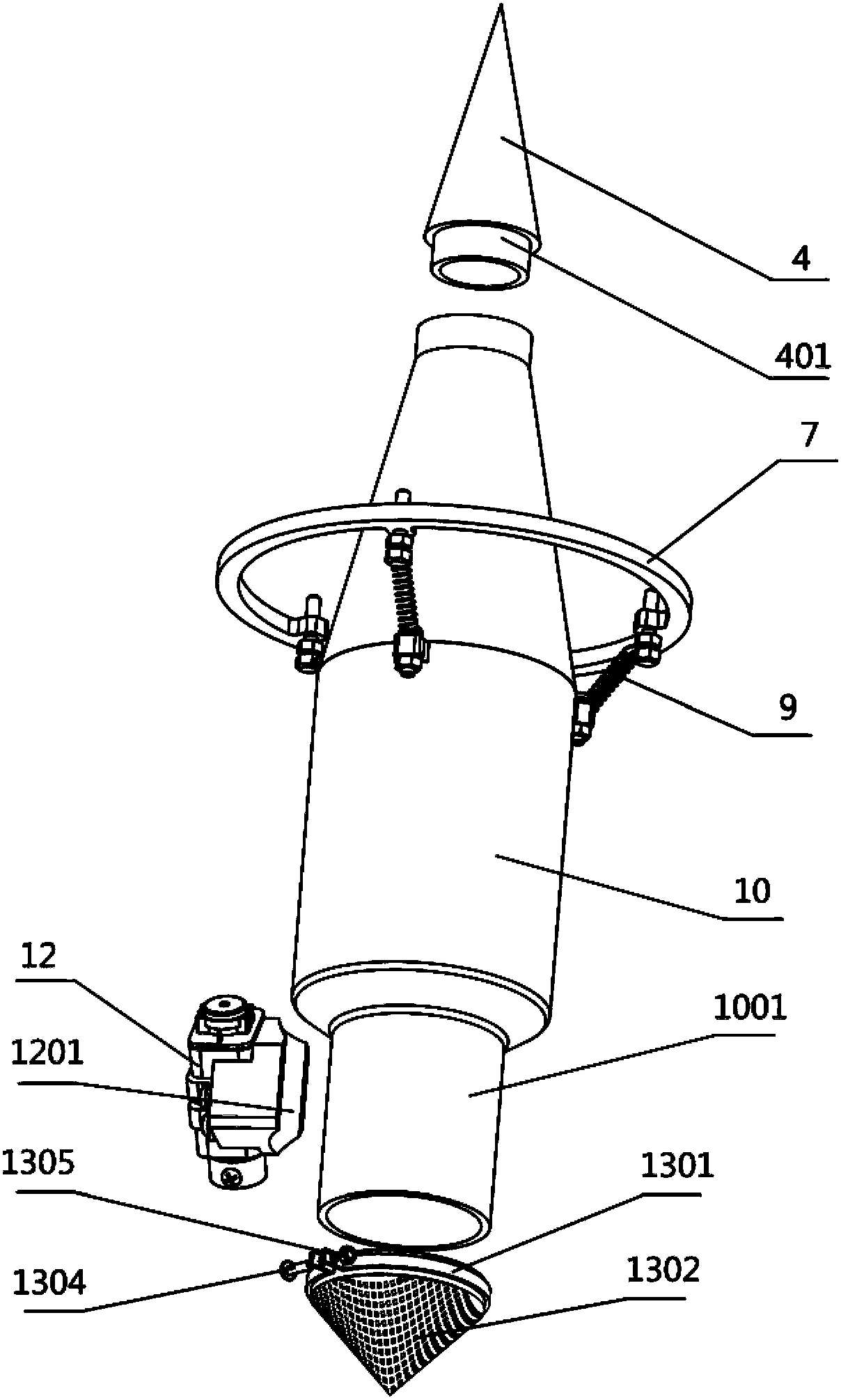

[0048] The gas-nano particle two-phase uniform fluid generation device provided by the invention includes a compressed gas flow control chamber and a nano particle vibration dosing device, wherein the nano particle vibration dosing device is installed inside the compressed gas flow control chamber. The compressed gas is fed into the compressed gas flow control chamber, and the nanoparticles supplied by the nanoparticle vibrating dosing device will be taken away by the flowing airflow and uniformly mixed with the compressed gas to form a gas-nanoparticle two-phase uniform fluid. The compressed gas flow control chamber can make the compressed gas passed in uniformly diffuse and shrink without backflow, so as to ensure that all supplied nanoparticles are taken away by the compressed air flow. The nanoparticle vibrating quantitative feeding device can quantitatively control the feeding rate of nanoparticles, change the content of nanoparticles in the gas-solid two-phase flow, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com