Injection mold for making helical fan

A technology for injection molds and fans, which is applied in the field of injection molds for making spiral fans, can solve the problems of high production cost, complex structure, and difficult quality assurance, and achieve the effect of simple demoulding, simple structure, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

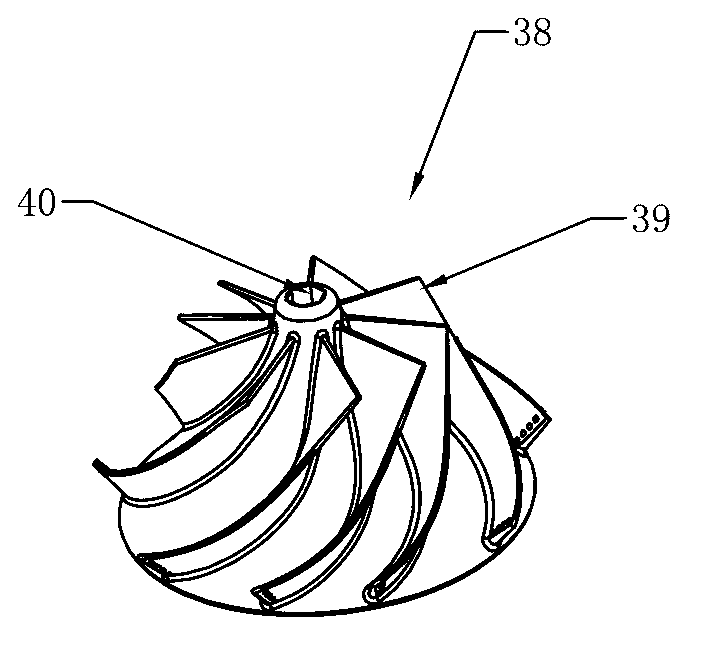

[0023] The spiral fan plastic part product of the present invention is as figure 1 As shown, the spiral fan 38 plastic product is a part with helical curved blades 39 and a stepped hole 40 in the middle. The material is ABS and the shrinkage rate is 0.5%. The structure of the part is more complicated, and it is not easy to demould.

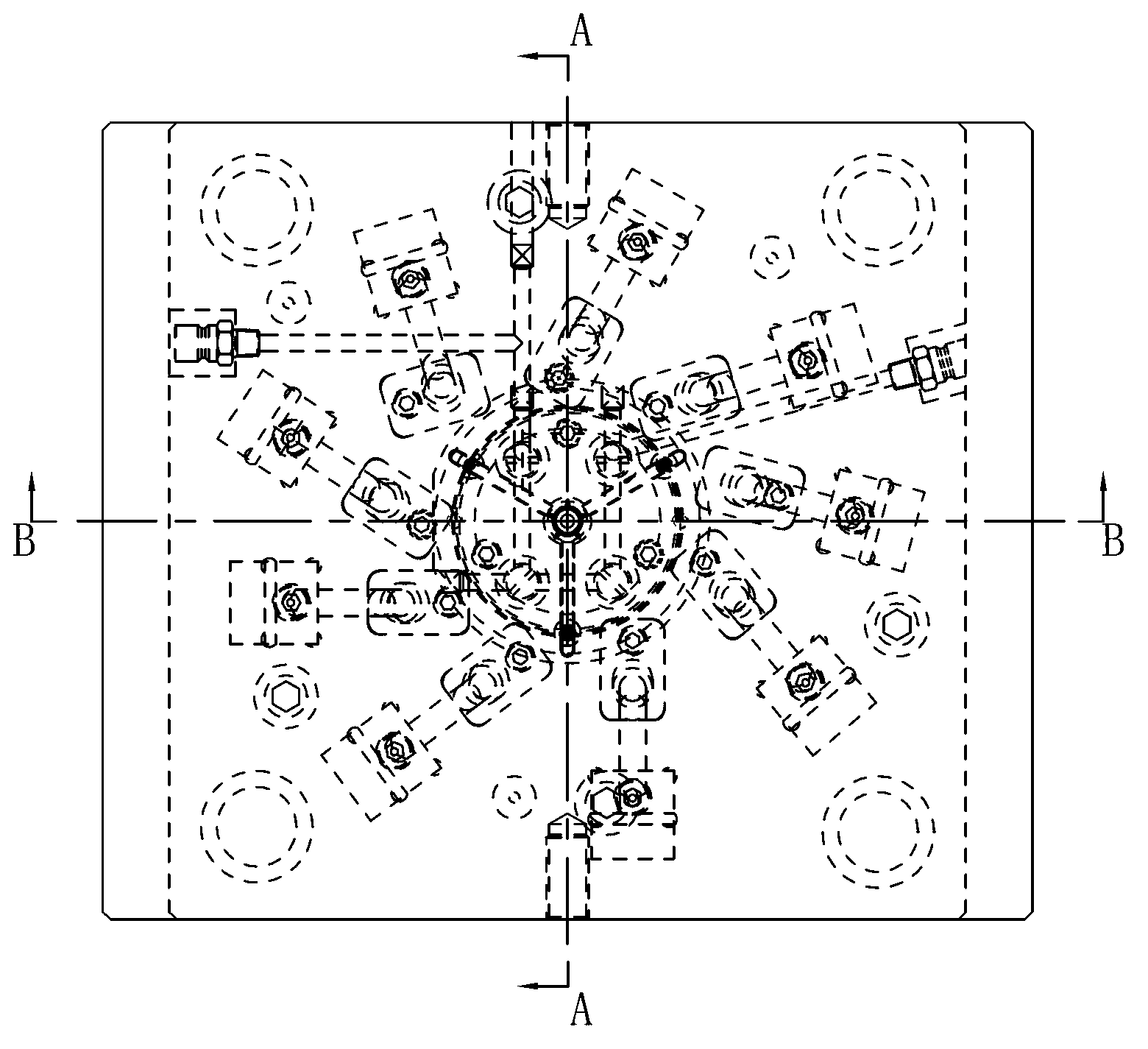

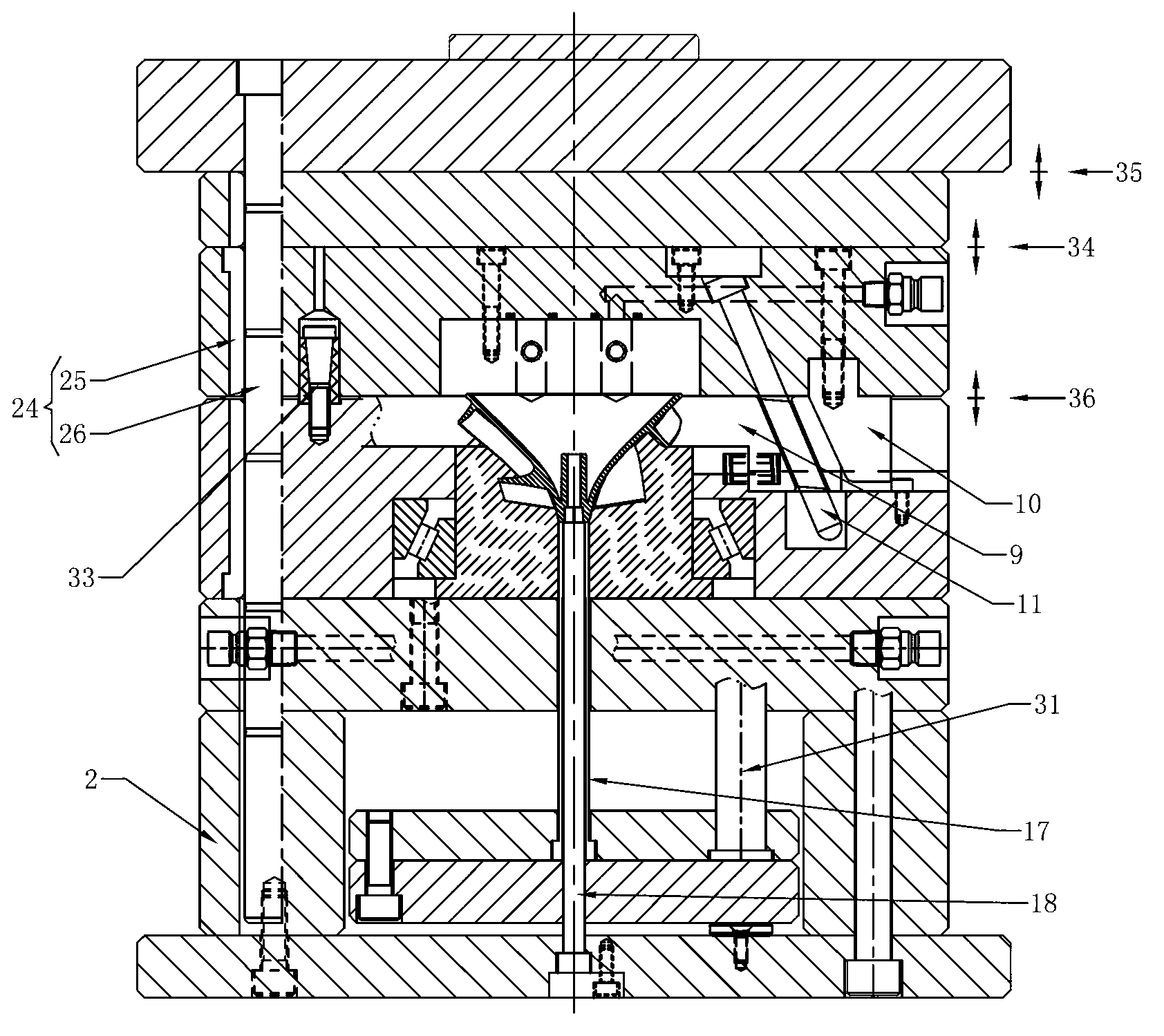

[0024] The injection mold for making spiral fan of the present invention is as figure 2 , 3 , 4, the injection mold includes a movable mold seat plate 1, a square iron 2, a supporting plate 3, a movable template 4, a fixed template 5, a front inner mold 6, a spiral core 7, a split type oblique bearing 8, a slide block 9. Shovel 10, inclin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com