Stop valve and concrete conveying system

A globe valve and conveying pipe technology, applied in the field of fluid material conveying system, globe valve and concrete conveying system, can solve the problems of high processing cost, high assembly cost, complicated structure of globe valve, increased assembly workload, etc. Low cost, stable and reliable work performance, reducing the effect of finishing surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

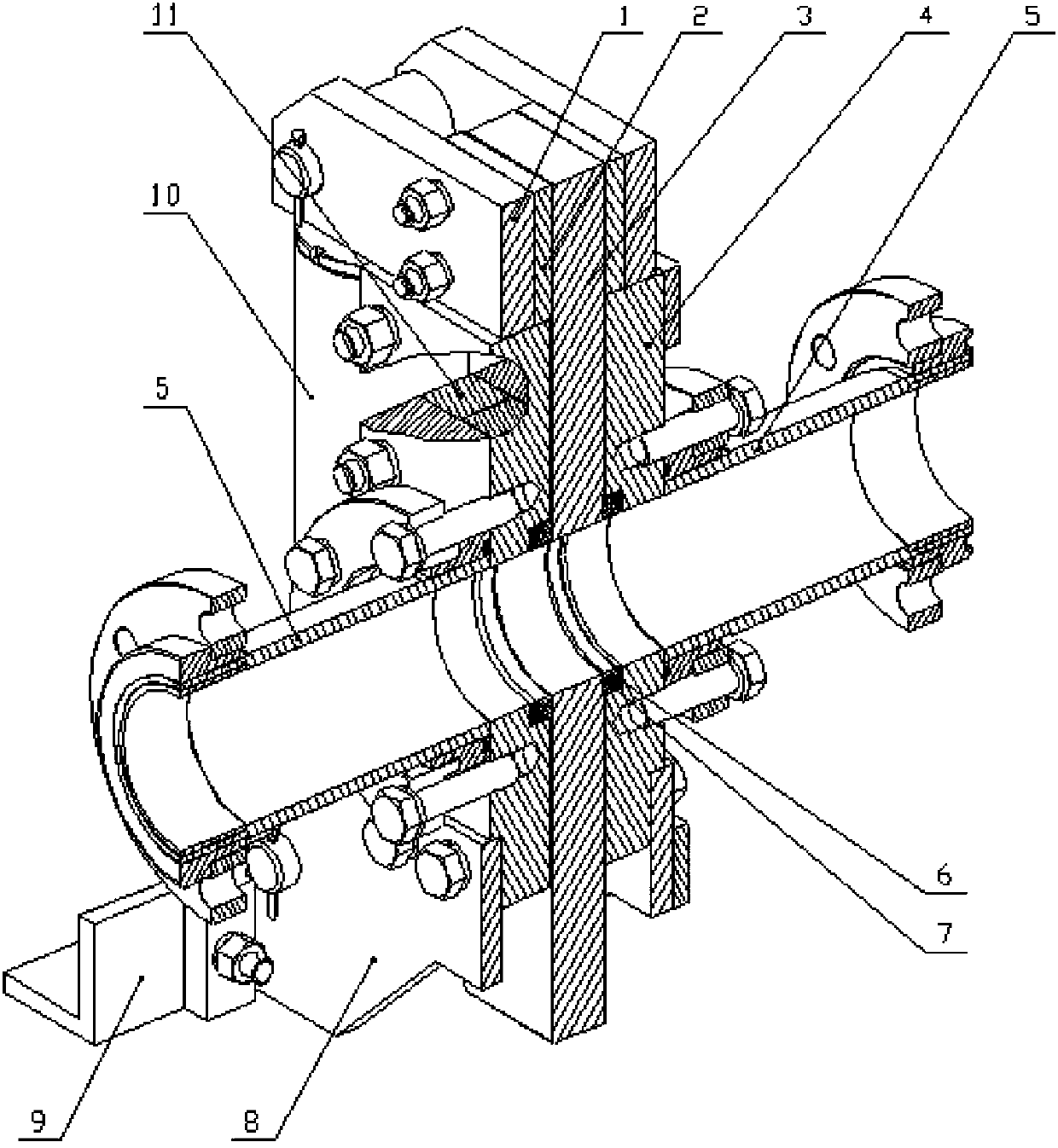

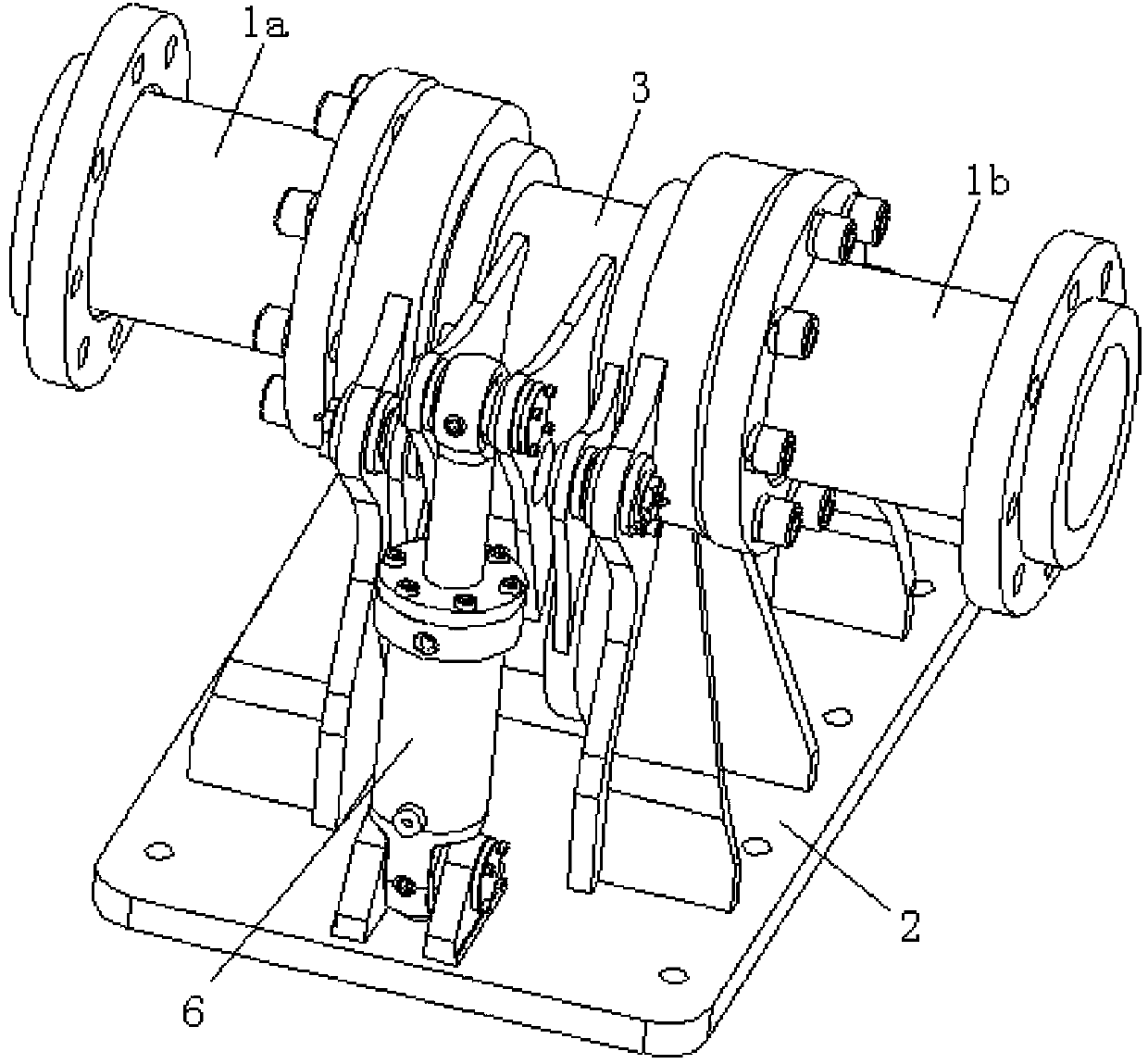

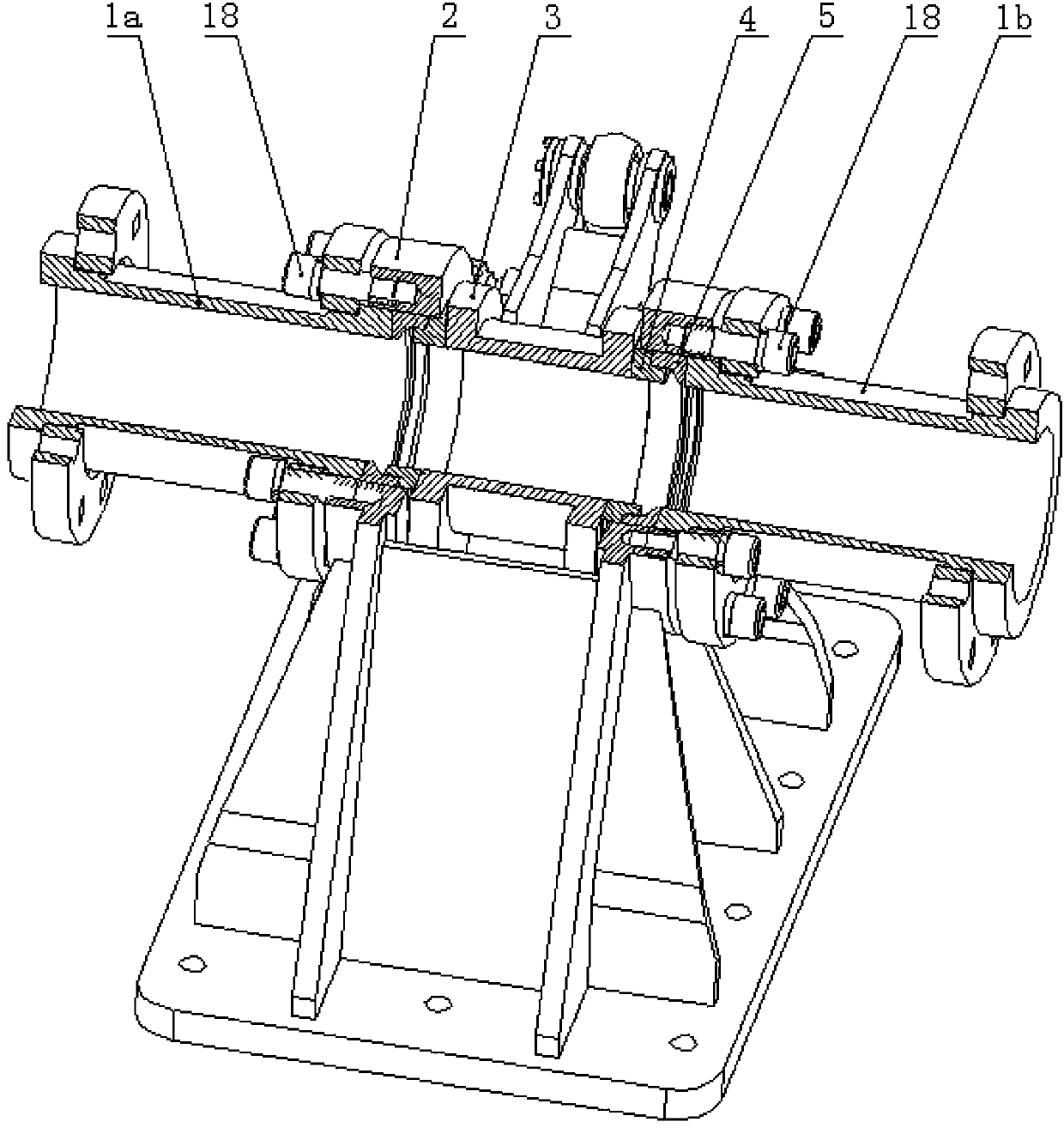

[0072] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

[0073] First of all, in the description of specific embodiments below, some orientation words used for ease of understanding, such as up, down, left, right, etc., are described according to the orientation shown in the drawings, but these orientation words are not Should constitute a limitation to the protection scope of the present invention, because the installation position of shut-off valve is various in practice, for example figure 1 The cut-off valve shown can be hoisted with the base facing up according to the requirements of the installation space during the actual installation process, so some ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com