Cutting system for shaping stage light beams and stage lamp

A technology of beam shaping and stage lighting, which is applied in the direction of light source fixing, lighting device parts, lighting devices, etc., can solve the problems of limited operating freedom of cutting components, slow cutting speed, inaccurate positioning, etc., and achieve convenient transportation and storage Placement, precise positioning of the cutting piece, and the effect of preventing motion movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

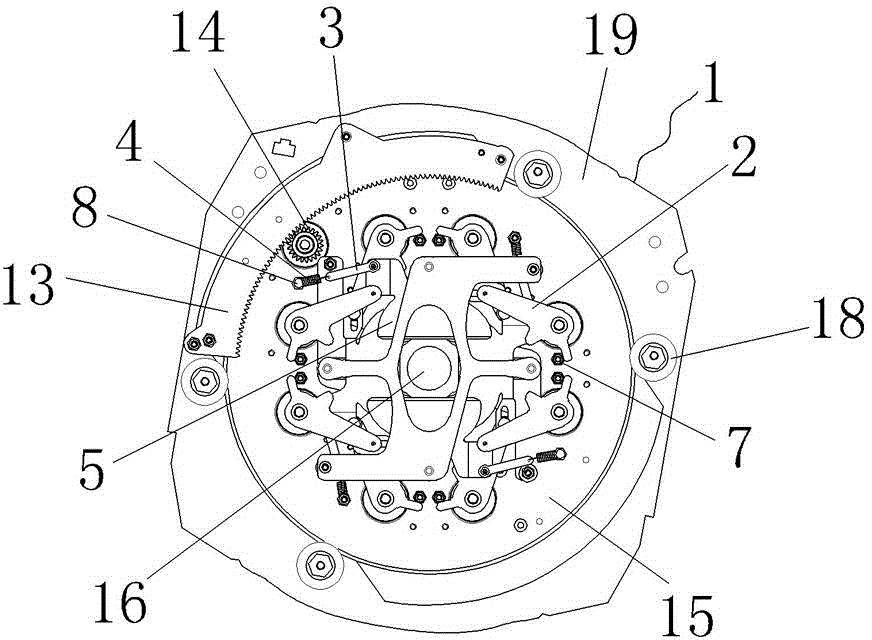

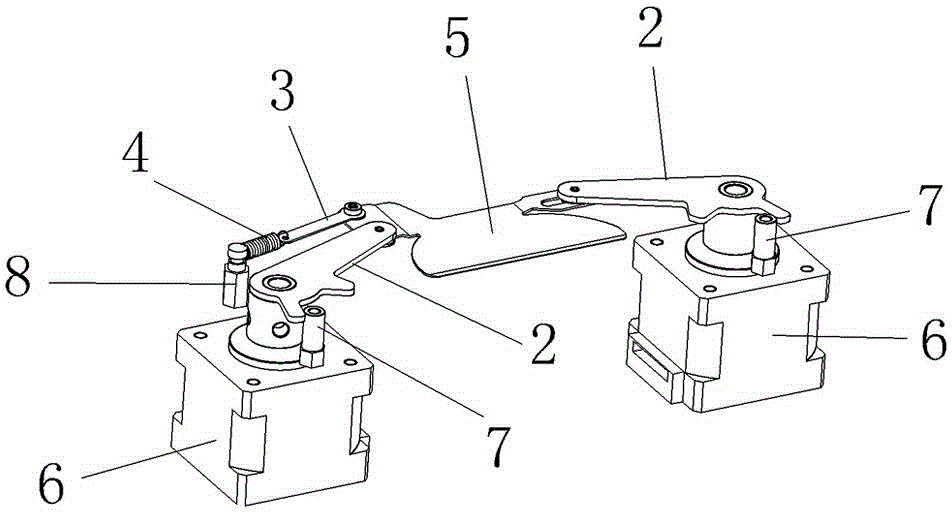

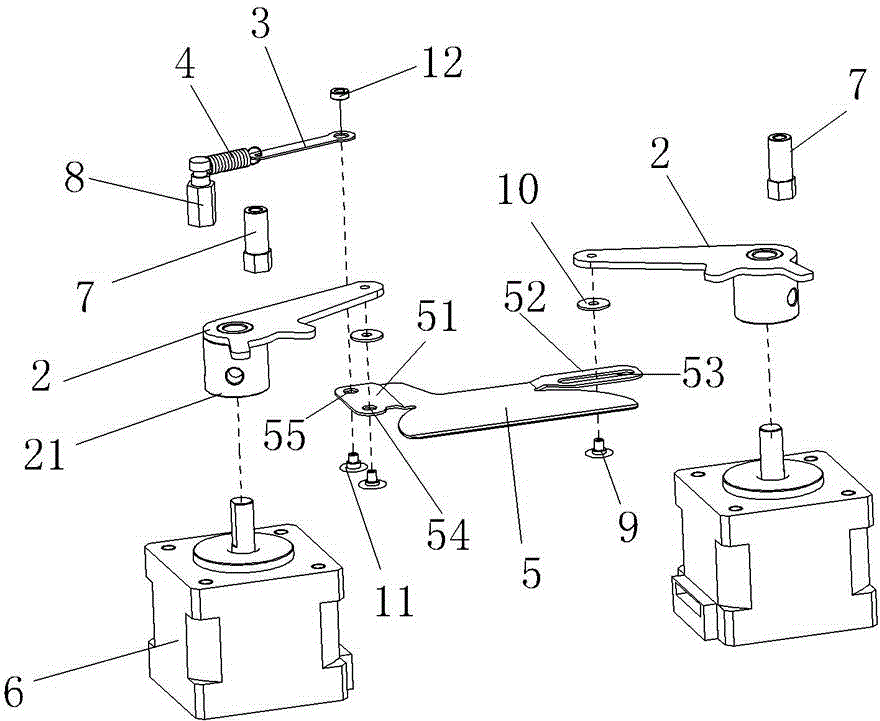

[0036] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] refer to Figure 1-Figure 6 , the cutting system used for stage lighting beam shaping includes:

[0038] Bracket 1, the bracket 1 includes a fixed frame 19 and a rotating disk 15, the fixed frame 19 is fixed on the support frame inside the lamp, the rotating disk 15 is connected to the fixed frame 19 through a rotating drive mechanism and can rotate relative to the fixed frame 19;

[0039] A cutting device consisting of four groups of cutting blades 5, each group of cutting blades 5 is arranged in a different plane perpendicular to the light beam, and each group of cutting blades 5 can move along the plane where it is located;

[0040] Four pairs of actuators, each pair of actuators are connected to a group of cutting blades 5; each actuator includes a drive motor 6 and a transmission mechanism, and the drive motor 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com