High-precision torque measurement device and method for petroleum pipeline dismounting frame

A technology of torque measurement and rack disassembly, which is applied in the field of petroleum machinery to achieve the effect of improving torque measurement accuracy, high reliability, and simple and reliable torque measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

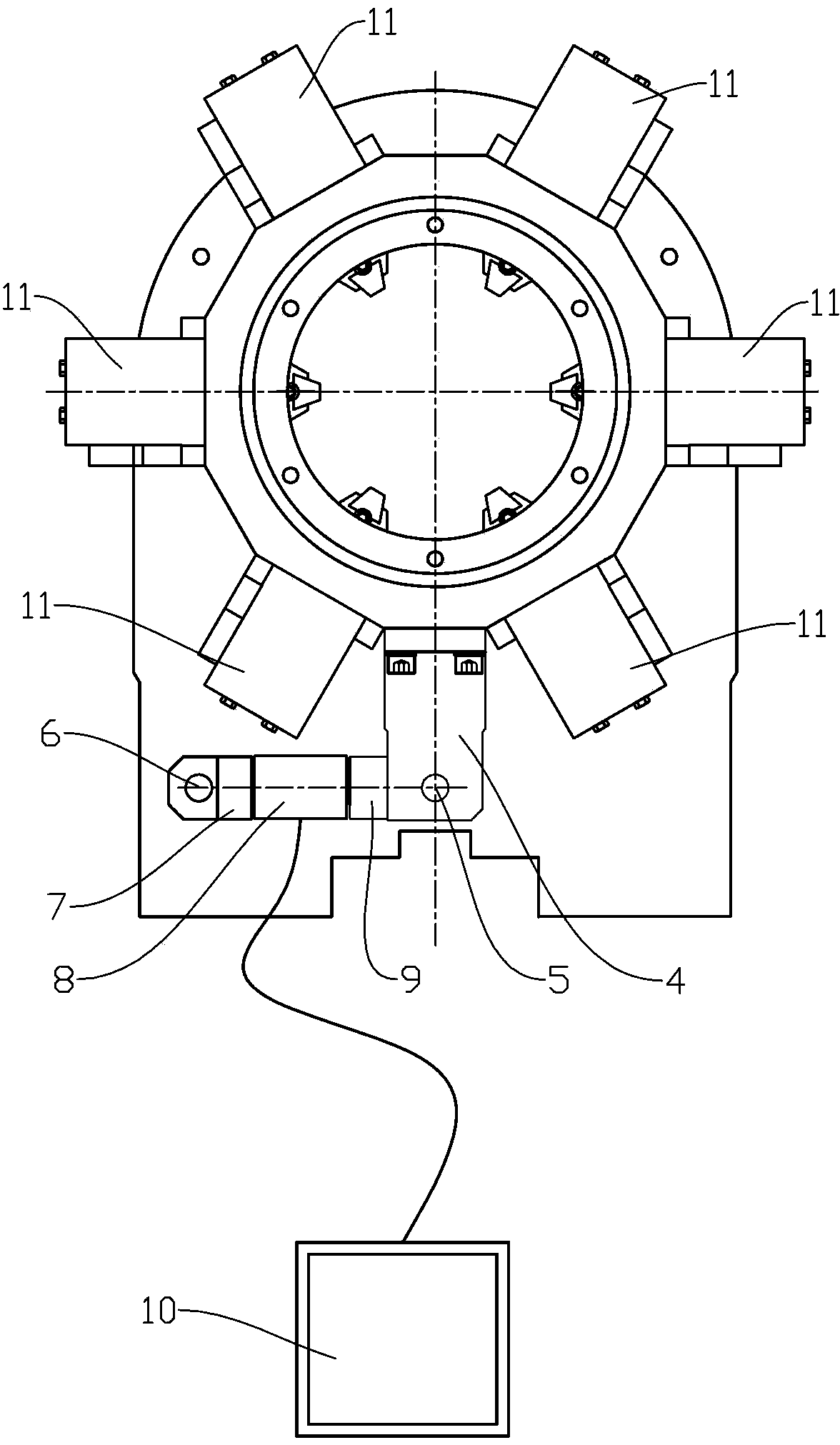

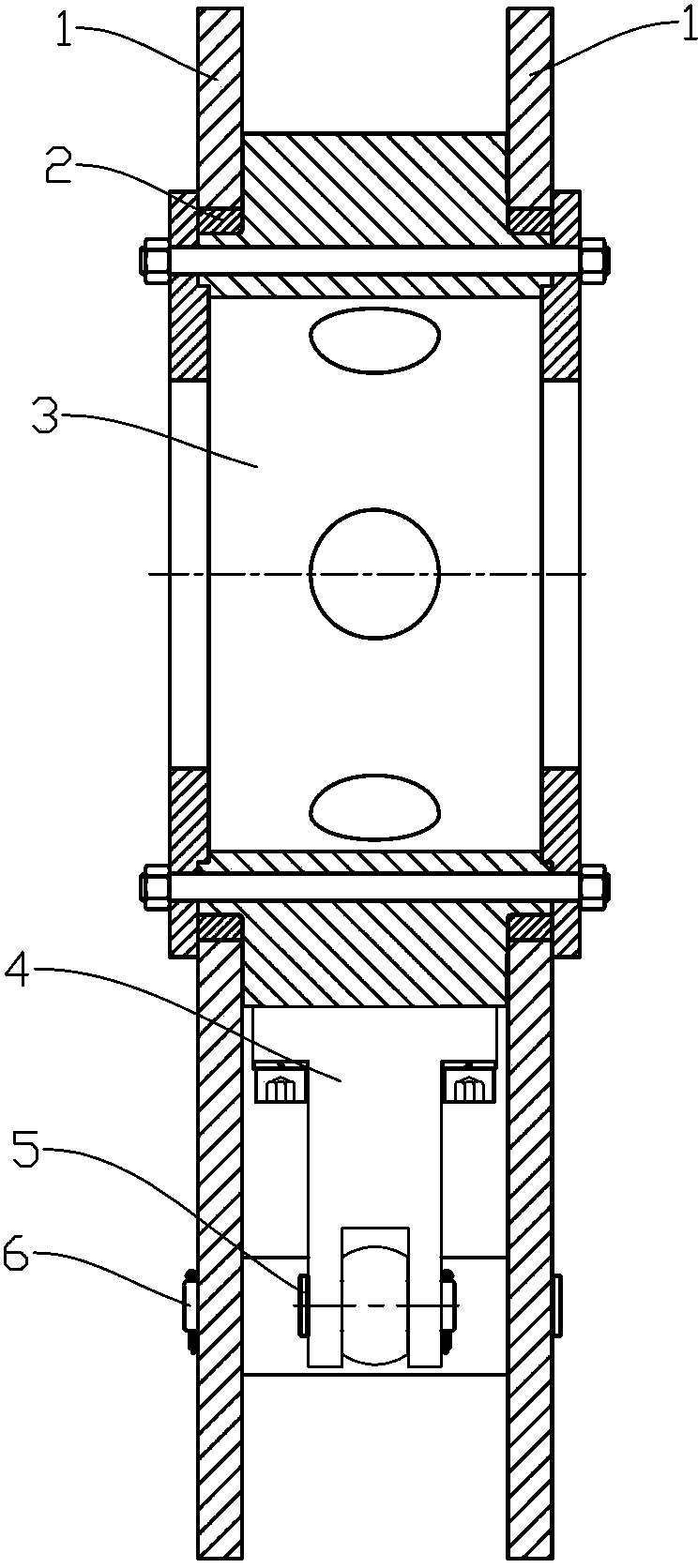

[0028] as attached figure 1 , figure 2 As shown, the first embodiment of the high-precision torque measuring device for oil pipe fitting disassembly rack includes a support plate 1 , a clamping body 3 , a tension pressure sensor 8 and a data acquisition and display system 10 .

[0029] The supporting plate 1 is a supporting part in the whole device, which plays a supporting and fixing role.

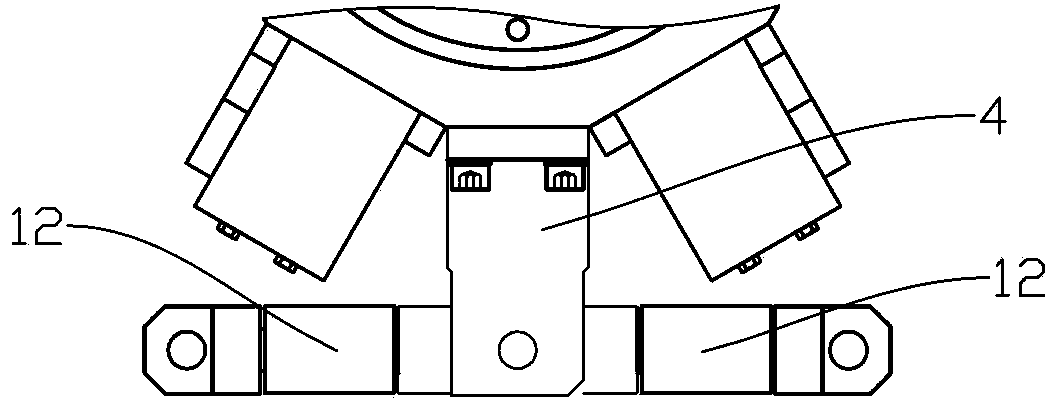

[0030] The clamping body 3 is an important part for clamping the workpiece and transmitting torque. The clamping body 3 is freely rotatably mounted on the support plate 1 through bearings. The clamping body 3 is provided with a clamping mechanism for clamping the workpiece. The clamping mechanism is composed of a plurality of hydraulic cylinders 11 arranged uniformly around the axis of the clamping body 3 and fixed on the clamping body 3 . A force-measuring rod 4 is provided along the radial direction of the rotation track of the clamping body 3 , and the force-measuring rod 4 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com