Sealing body for electrolytic capacitor and electrolytic capacitor

A technology for electrolytic capacitors and sealing bodies, which is applied to liquid electrolytic capacitors, capacitor casings/packages, capacitor parts, etc., can solve the problems of large waste of materials and troublesome lamination processes, and achieve the effect of excellent heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

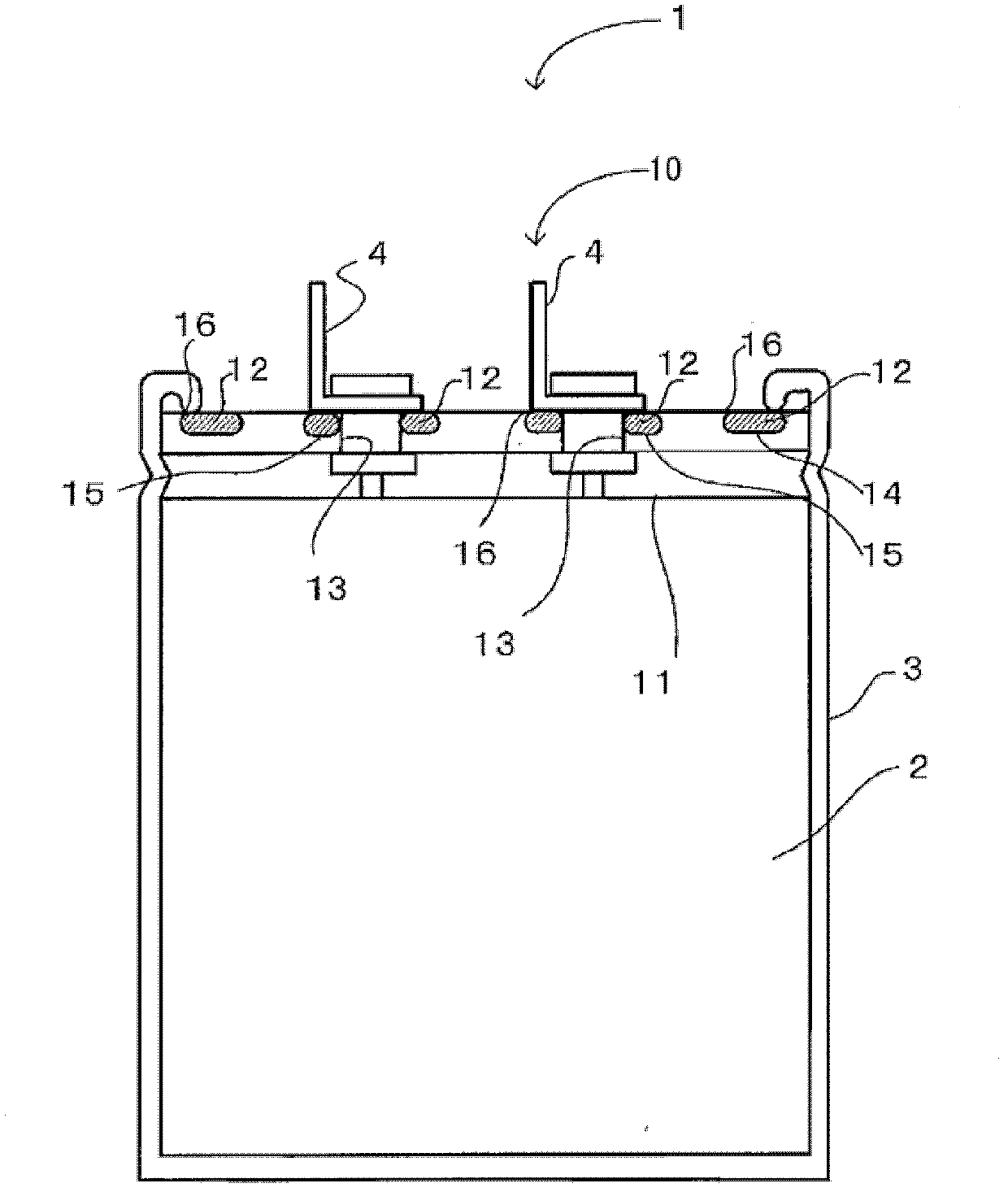

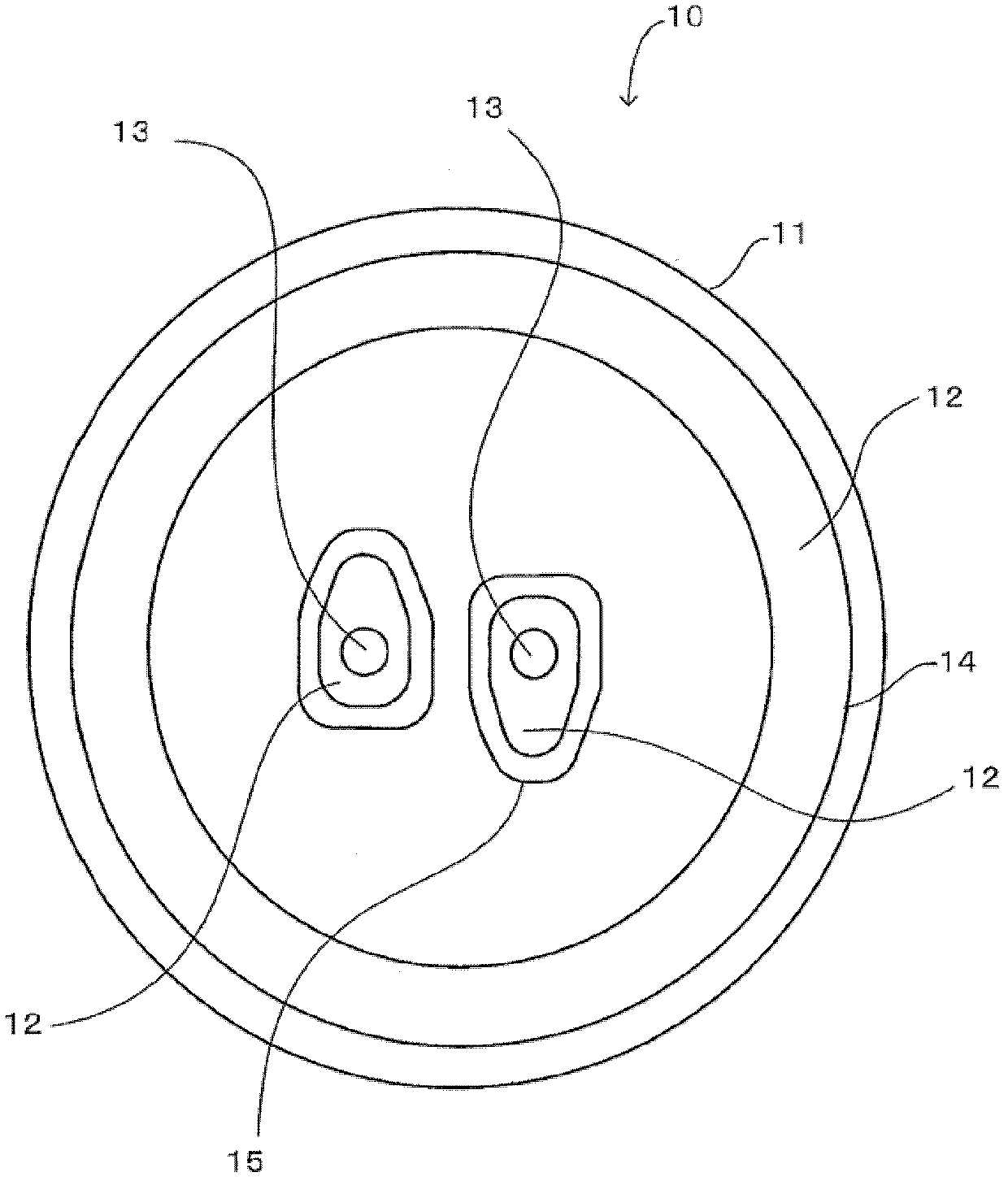

[0027] use Figure 1 ~ Figure 3 The first embodiment will be described.

[0028] (constitute)

[0029] Such as figure 1 As shown, the electrolytic capacitor 1 of the present embodiment includes a capacitor element 2 , a case 3 , electrodes 4 provided with connection terminals for connection to external devices, and a disc-shaped sealing body 10 . The sealing body 10 has a sealing plate 11 and an elastic body 12 . The sealing plate 11 is produced by injection molding a thermoplastic resin as an example. The elastic body 12 is formed by integrally molding a thermoplastic resin on the sealing plate 11 by bimaterial molding. Bi-material forming is integrally produced by combining different materials using the same mold.

[0030] That is, the above-mentioned sealing plate 11 is as figure 2 It has a disc shape as shown. Syndiotactic polystyrene resin (SPS) is mentioned as a thermoplastic resin used as the sealing plate 11. As shown in FIG. The syndiotactic polystyrene resi...

no. 2 Embodiment approach

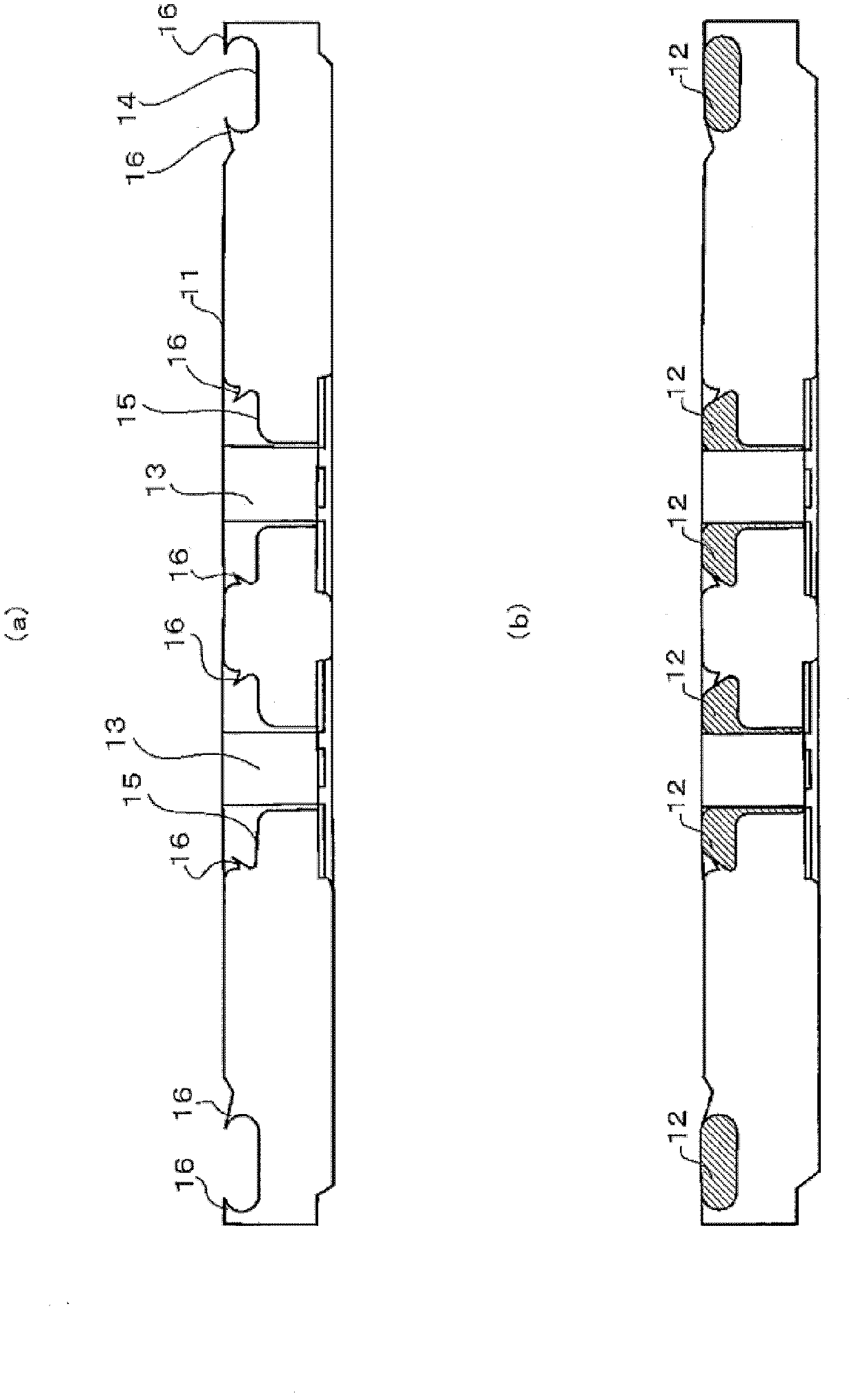

[0047] Use below Figure 4 The second embodiment will be described. and, figure 1 , figure 2 The configuration shown is the same as that of the first embodiment, and description thereof will be omitted.

[0048] (constitute)

[0049] The sealing plate 11 of the present embodiment is as Figure 4 As shown in (a), protruding portions 17 that become protrusions 16 after deformation are provided at the edge portions of the respective grooves. The protruding portion 17 is formed along a direction parallel to the inner surface of the groove portion at an edge portion of the annular groove portion 14 and the electrode groove portion 15 . That is, the protruding portion 17 stands substantially upward from the openings of the groove portions 14 and 15 so as to stand up from the sealing plate 11 . Therefore, in the state where the sealing plate 11 is molded, the opening of each groove 14, 15 is equal to the width of each groove 14, 15, unlike the case where the opening is narrow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com