Damping rubber gasket

A vibration-damping rubber and grooving technology, which is applied in the field of vibration-damping rubber pads, can solve problems such as uncertain contact area, unsatisfactory vibration-damping effect, and small contact area, so as to increase flexibility, increase the vibration isolation frequency range, and improve Effect of Vibration Isolation Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

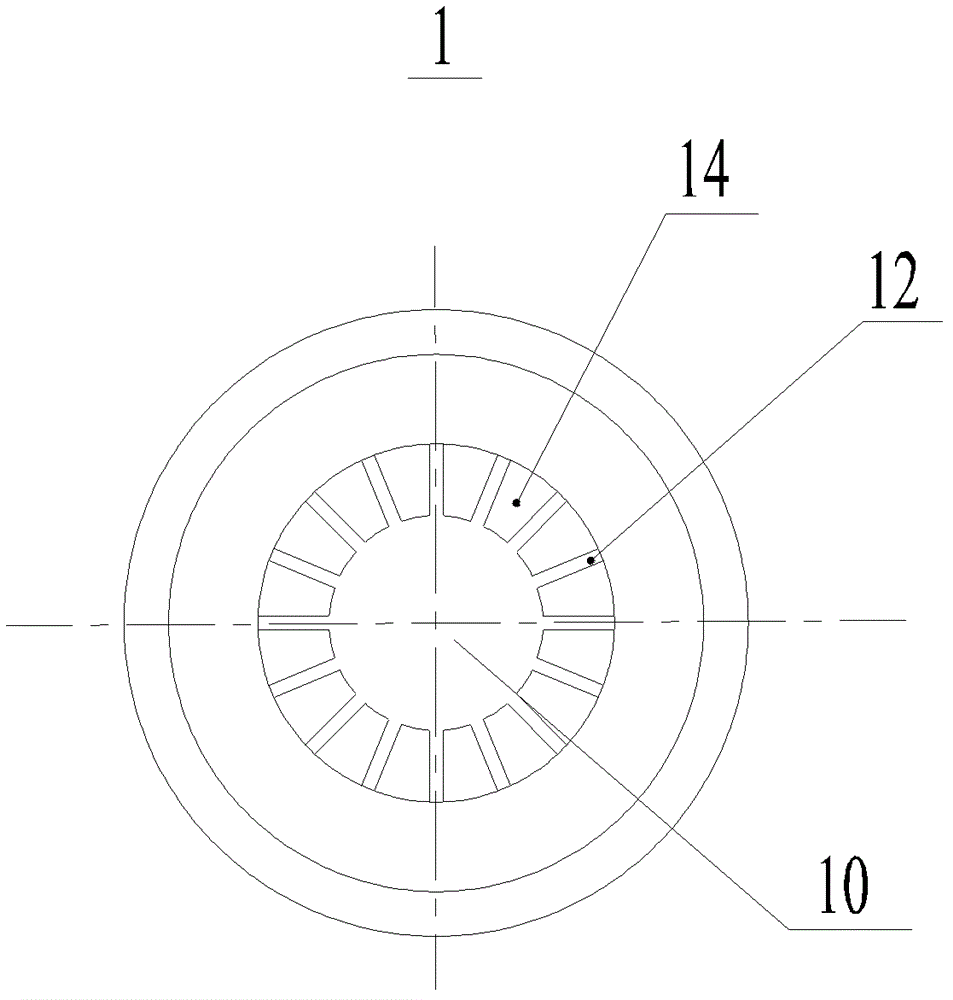

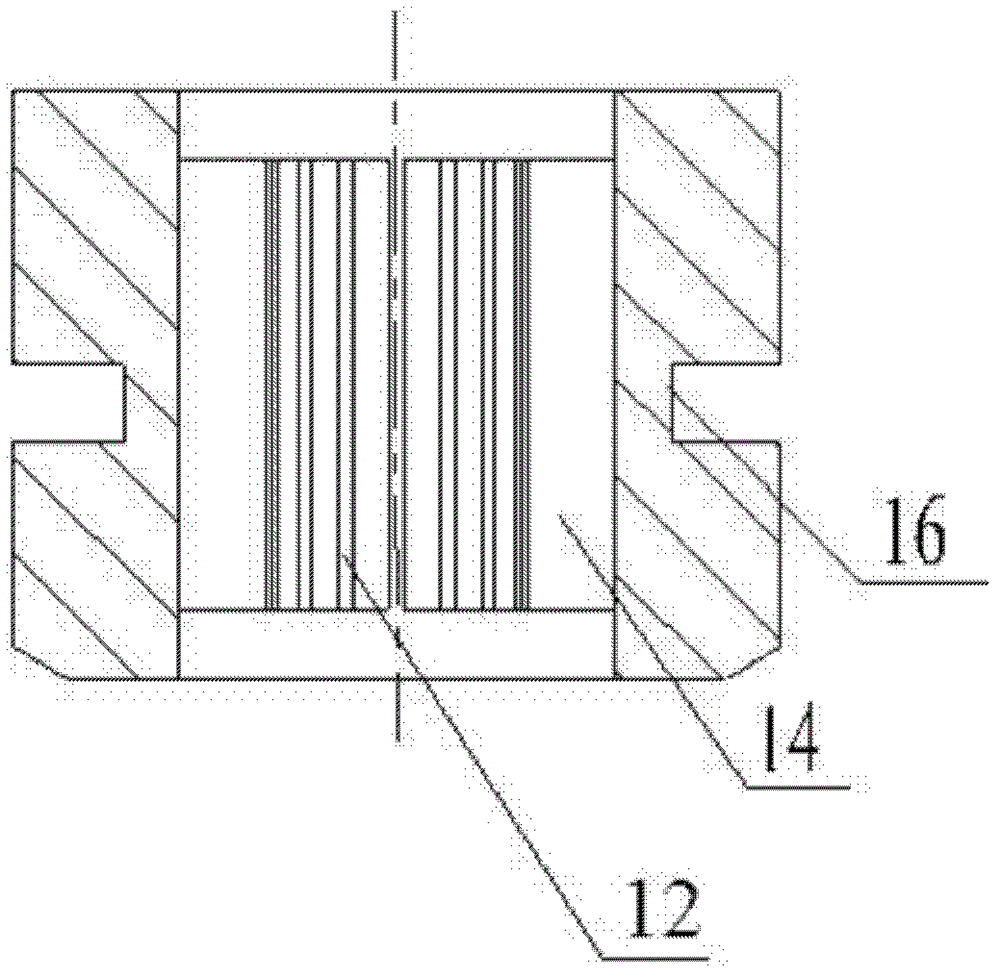

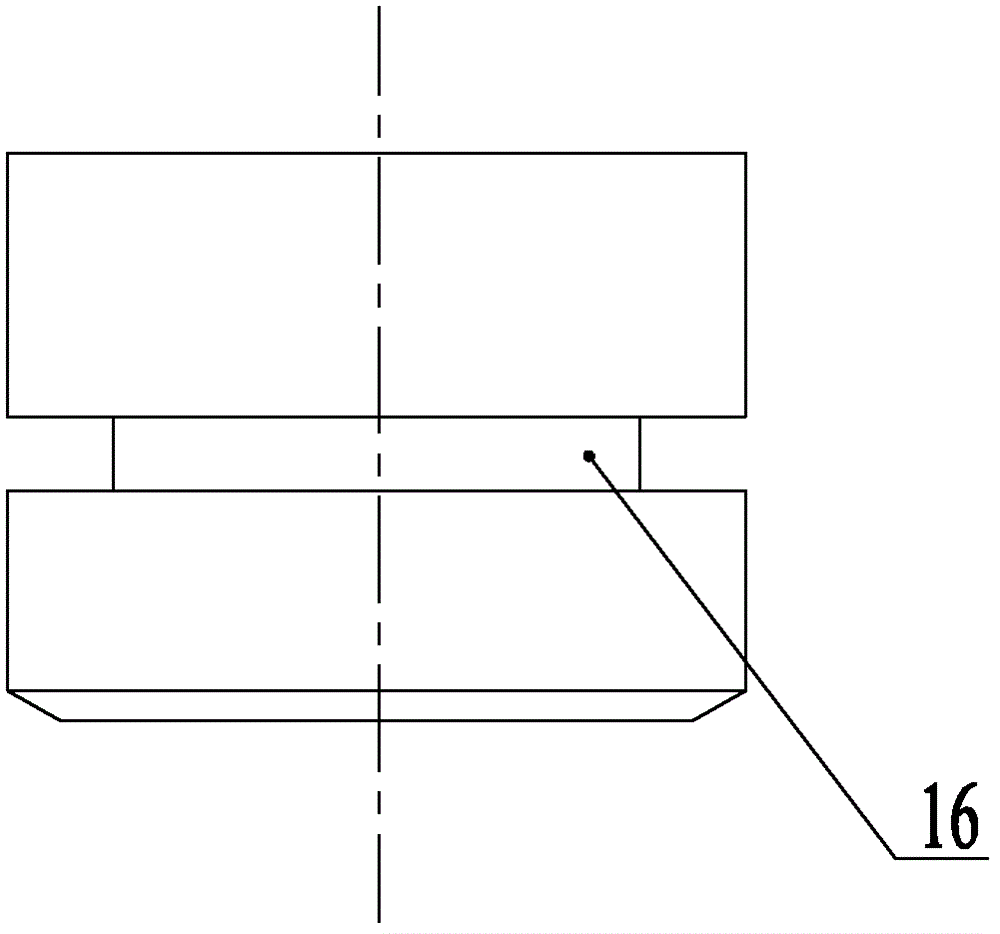

[0022] combine figure 1 As shown, the figure shows a top view of a vibration-damping rubber pad 1 of the present invention. At the central axis of the vibration-damping rubber pad 1 , an inner hole 10 is provided. The shape of the inner hole 10 is a circular hole. The inner hole 10 extends axially along the vibration-damping rubber pad 1 and runs through the vibration-damping rubber pad 1 . The inner hole 10 is provided to fit with the motor mounting bolts during installation. The vibration-damping rubber pad 1 also includes a plurality of slots 12, which are defined on the sidewall of the inner hole 10 in the axial direction and arranged at intervals in the circumferential direction. A conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com