Driving method for plasma display panel, and plasma display device

A technology for display panels and driving methods, applied to static indicators, color TV parts, TV system parts, etc., can solve problems such as wrong write discharge, image display quality deterioration, etc., to achieve suppression of abnormal discharge, The effect of improving image display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

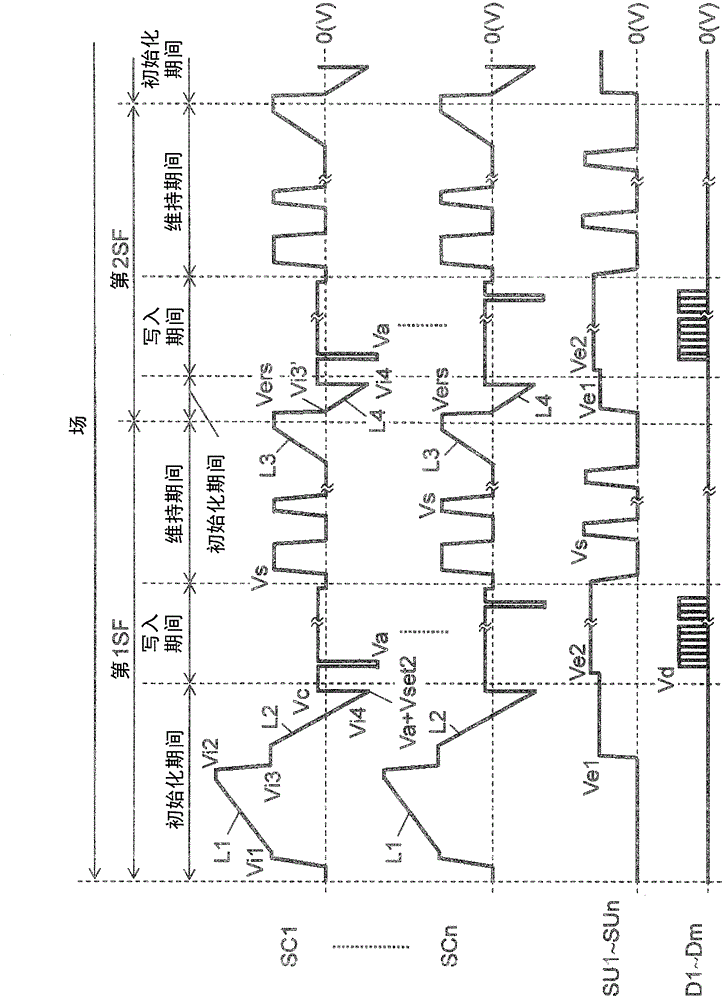

Embodiment approach 1

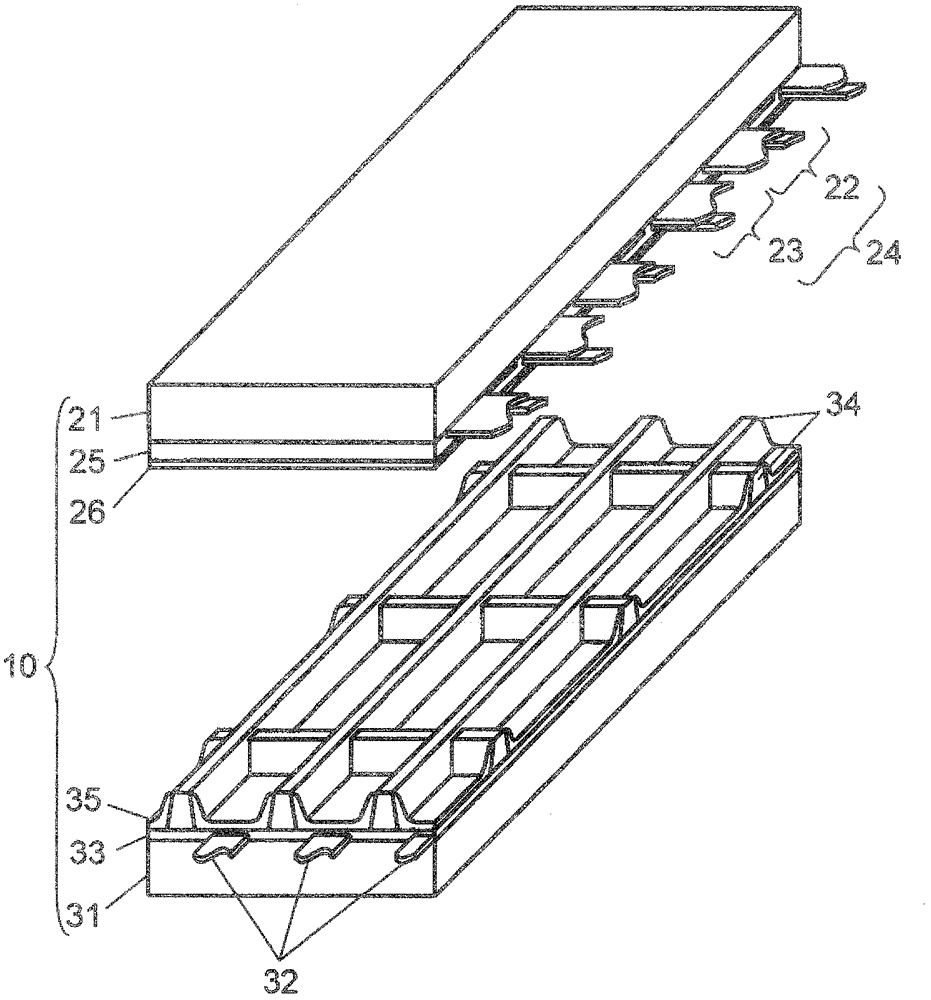

[0039] figure 1 It is an exploded perspective view showing the structure of the panel 10 in Embodiment 1 of this invention. On front panel 21 made of glass, a plurality of display electrode pairs 24 including scan electrodes 22 and sustain electrodes 23 are formed. Furthermore, dielectric layer 25 is formed to cover scan electrodes 22 and sustain electrodes 23 , and protective layer 26 is formed on dielectric layer 25 . The protective layer 26 is formed of a material mainly composed of magnesium oxide (MgO).

[0040] A plurality of data electrodes 32 are formed on rear plate 31 , dielectric layer 33 is formed to cover data electrodes 32 , and grid-shaped partition walls 34 are further formed thereon. Further, phosphor layers 35 that emit light of each color of red (R), green (G) and blue (B) are provided on the side surfaces of the barrier ribs 34 and the dielectric layer 33 .

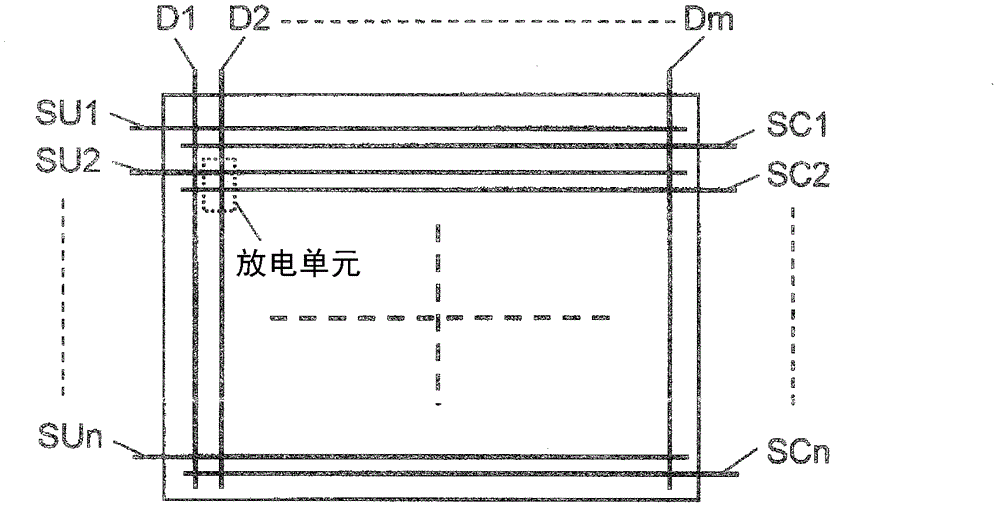

[0041] Front plate 21 and rear plate 31 are arranged to face each other so that display electrod...

Embodiment approach 2

[0119] In this embodiment, an example of operation when the gradation value of the other discharge cell is adaptively selected to be changed to one of the two gradation values based on a display image when the erroneous writing occurrence mode occurs will be described.

[0120] Figure 9 It is a circuit block diagram of plasma display device 2 in Embodiment 2 of the present invention. The plasma display device 2 has: a panel 10, an image signal processing circuit 41, a data electrode drive circuit 42, a scan electrode drive circuit 43, a sustain electrode drive circuit 44, a timing generation circuit 57, an APL detection circuit 49, and a circuit module that provides all A power circuit (not shown) that requires power. Among them, each circuit module except the APL detection circuit 49 and the timing generation circuit 57 is the same as that in Embodiment 1. Figure 4 The shown circuit blocks with the same name perform the same operation for the same structure.

[0121] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com