Multi-gap pseudospark electron beam source capable of suppressing flashover

An electron beam source and multi-gap technology, applied in the direction of solid cathode components, etc., can solve the problems of damage to the discharge chamber, breakdown of the isolation insulating sheet, and limitation of the performance of the electron beam, so as to achieve the improvement of the breakdown voltage of the beam source and the suppression of abnormal discharge , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

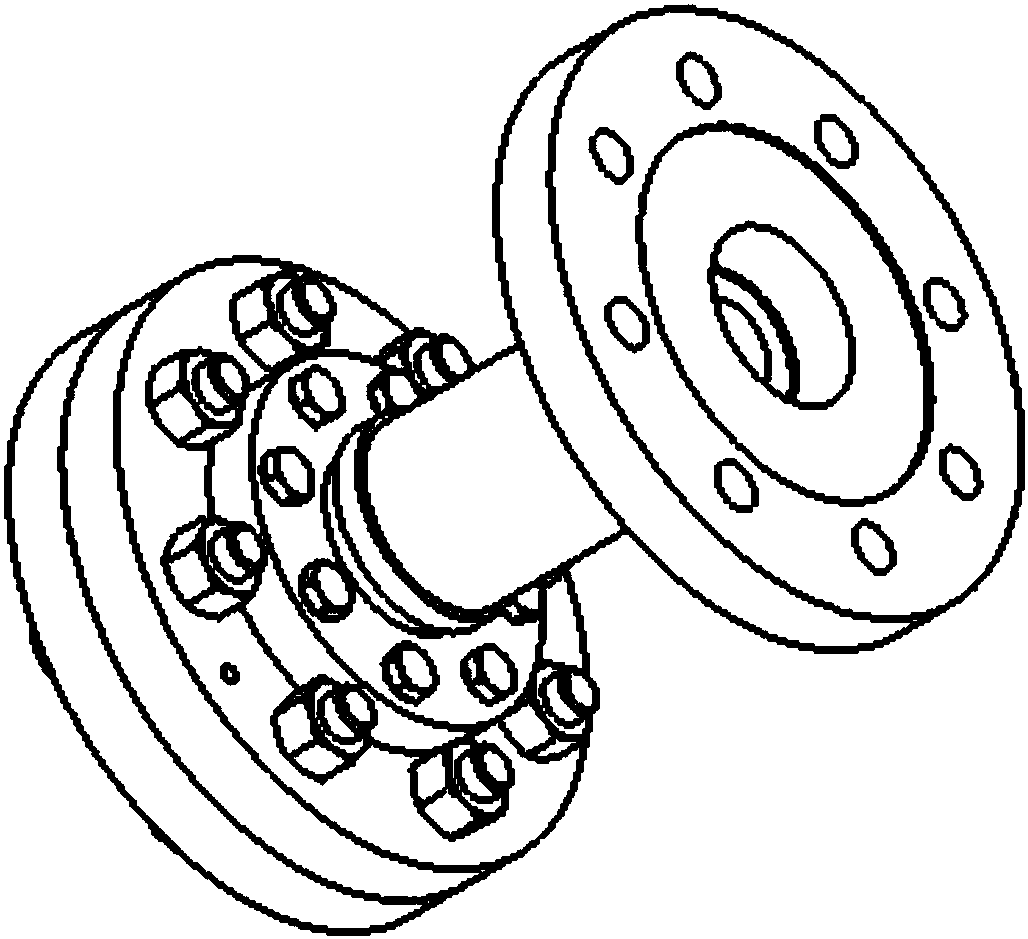

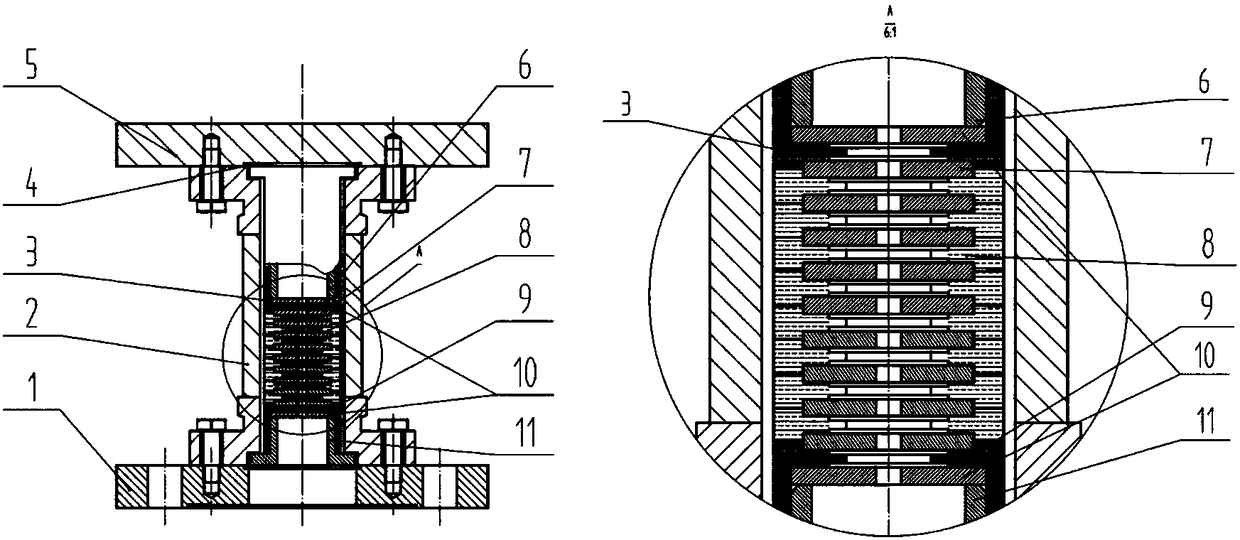

[0025] Such as figure 2 As shown, this embodiment includes: sequentially screwing the blind flange 5, the ceramic spacer 2 and the through-hole flange 1 to form an external support; the hollow electrodes 6, 11 and their insulating sleeves 3, 9 symmetrically placed at both ends of the ceramic spacer 2 , the intermediate electrodes 7 and intermediate insulating sheets 8 arranged alternately in the ceramic spacer 2 form a discharge cavity. The discharge chamber is axially positioned in the external support by the metal seal ring 4 .

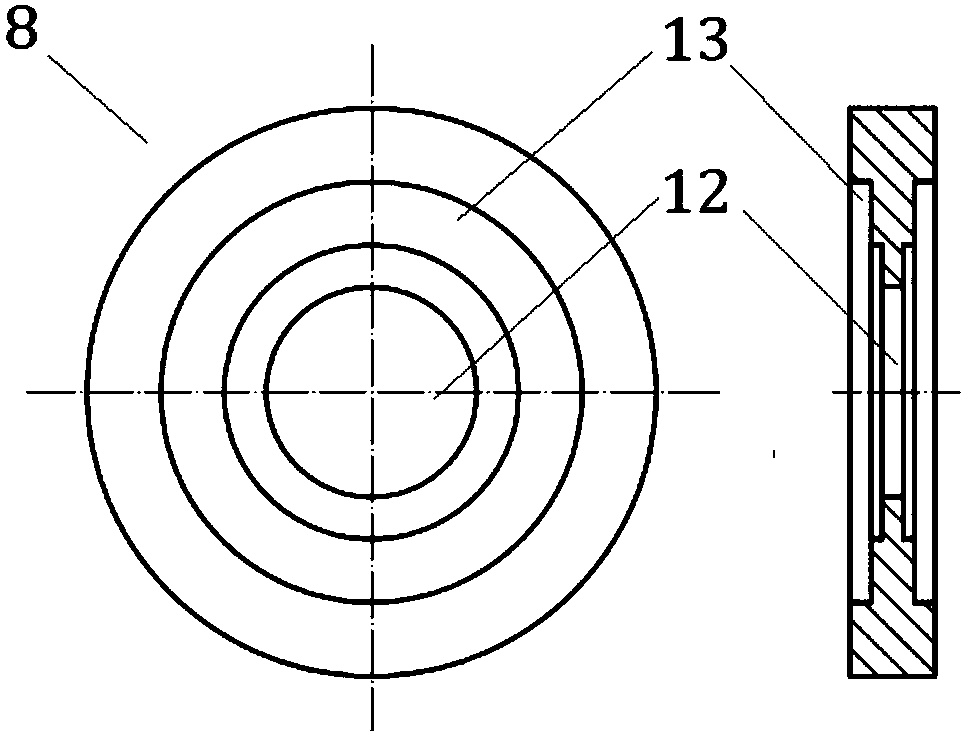

[0026] Such as Figure 4 The shown cathode insulating sleeve 3 surrounds the hollow cathode 6, and as figure 2 The way shown is installed in the ceramic sleeve 2 . The central through hole 12 at the bottom of the cathode insulating sleeve 3 provides a discharge gap. Such as Figure 4 The cathode insulating sleeve 3 shown has a counterbore 13 coaxial with the middle through hole 12, and the depth of the counterbore is half the thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com