Copper material for high-purity copper sputtering target, and high-purity copper sputtering target

A sputtering target and high-purity technology, applied in the field of copper raw materials for high-purity copper sputtering targets and high-purity copper sputtering targets, can solve the problem of rising manufacturing costs and the inability to stably form miniaturized and thinned wiring films , abnormal discharge and other problems, to achieve the effect of low cost, suppression of abnormal discharge, and stable film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

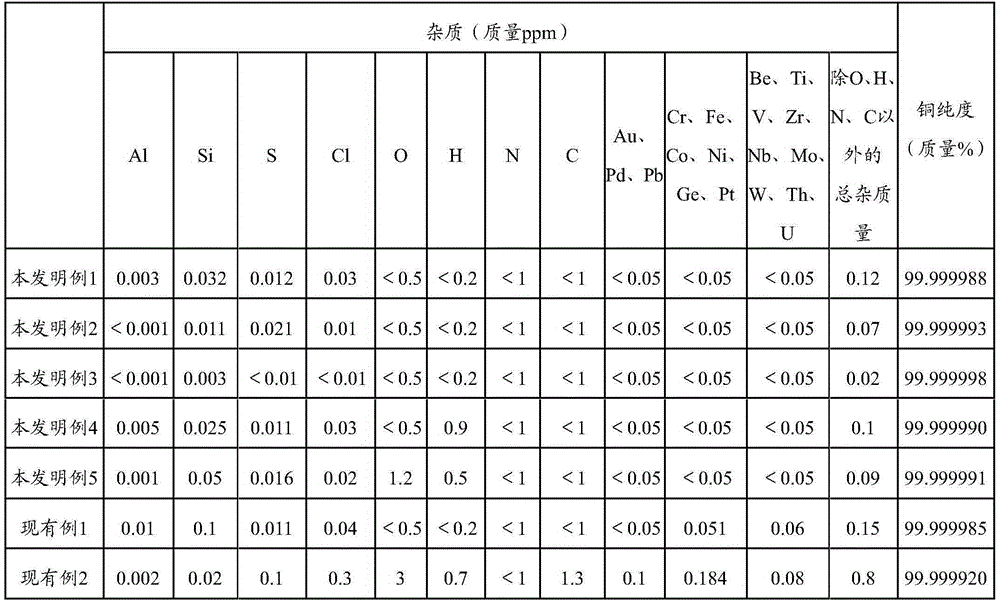

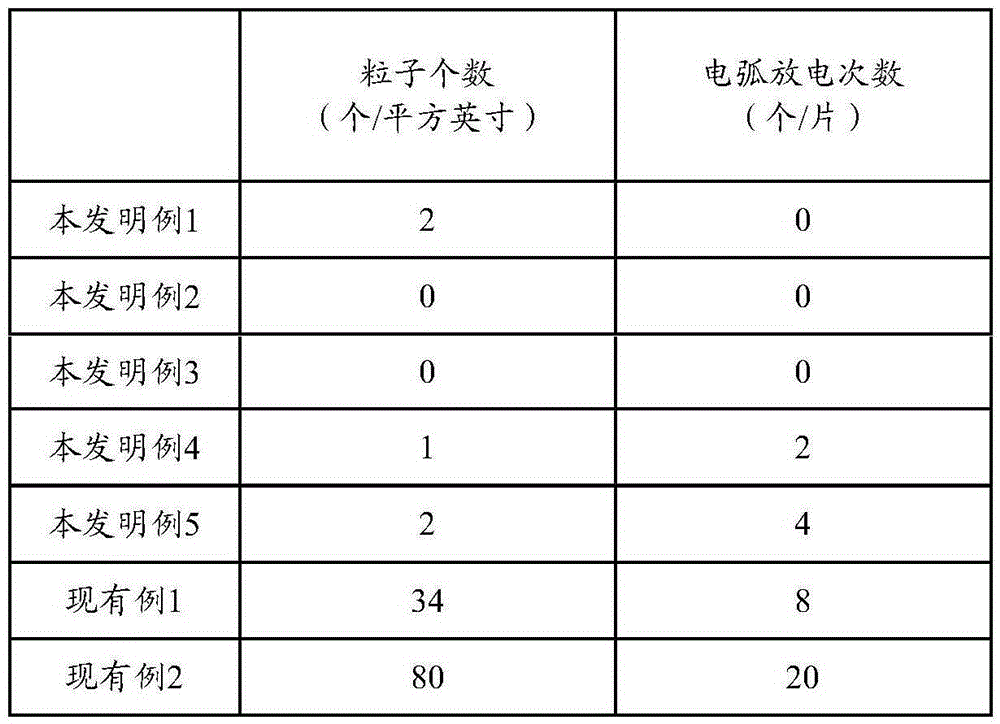

[0077] Hereinafter, the result of the evaluation test which evaluated the copper raw material for high-purity copper sputtering targets of embodiment mentioned above, and a high-purity copper sputtering target is demonstrated.

[0078] (Example 1-5 of the present invention)

[0079] Using electrolytic copper whose Al content is 1 mass ppm or less, Si content is 1 mass ppm or less, and other impurities (other than O, H, N, and C) are 20 mass ppm or less as a raw material, under the electrolytic purification conditions exemplified in the embodiment Electrolytic purification was repeated twice to produce a copper raw material (copper raw material).

[0080] The raw material produced by the above-mentioned production method was charged into a crucible made of high-purity carbon (carbon crucible), and vacuum melting was carried out at 1130° C. (pressure 10 -5 Pa). In addition, after melting under vacuum, it was held at a temperature of 1150° C. for 30 minutes. Thereafter, in a v...

example 1

[0083] Using electrolytic copper with Al content of 2 mass ppm or less, Si content of 3 mass ppm or less, and other impurities (other than O, H, N, and C) of 20 mass ppm or less as the raw material, repeated electrolysis using copper nitrate electrolyte Purification was performed twice to obtain a copper raw material having an Al content of 0.005 mass ppm and a Si content of 0.06 mass ppm.

[0084] The raw material produced by the above-mentioned production method was put into a carbon crucible, melted at 1130°C in an Ar atmosphere, and held at a temperature of 1150°C for 30 minutes. Thereafter, the melted raw material was poured into a carbon mold in an Ar atmosphere to produce a high-purity copper ingot with a diameter of 200 mm×a height of 800 mm. Table 1 shows the composition of the obtained ingot.

[0085] The manufactured high-purity copper ingot is forged at 500°C, the obtained high-purity forged block is cut into a diameter of 300mm×height of 15mm, and the cut out for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com