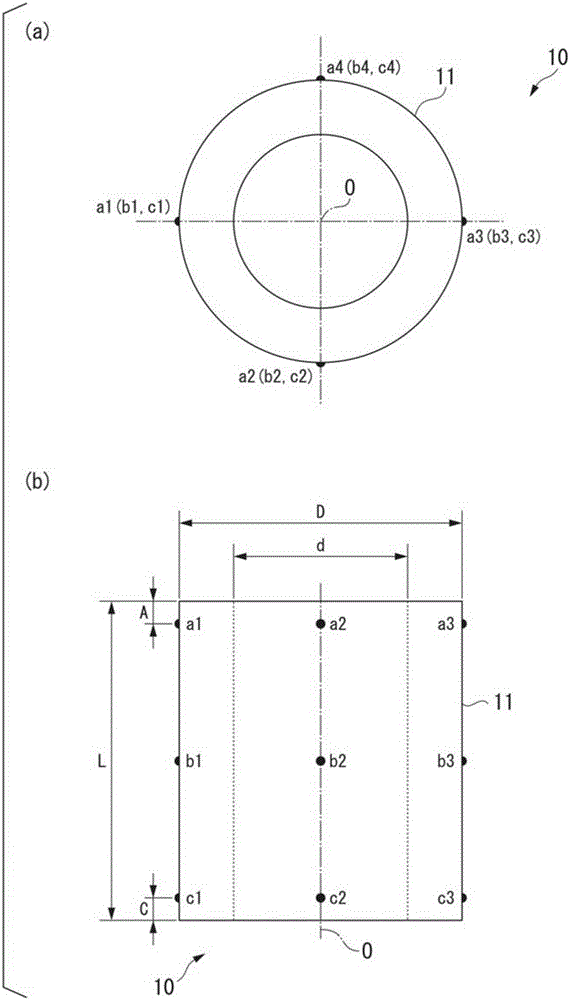

Material for cylindrical sputtering target

A sputtering target and cylindrical technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of uneven wiring film thickness and inability to form wiring film, etc. To achieve the effect of suppressing the generation of abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

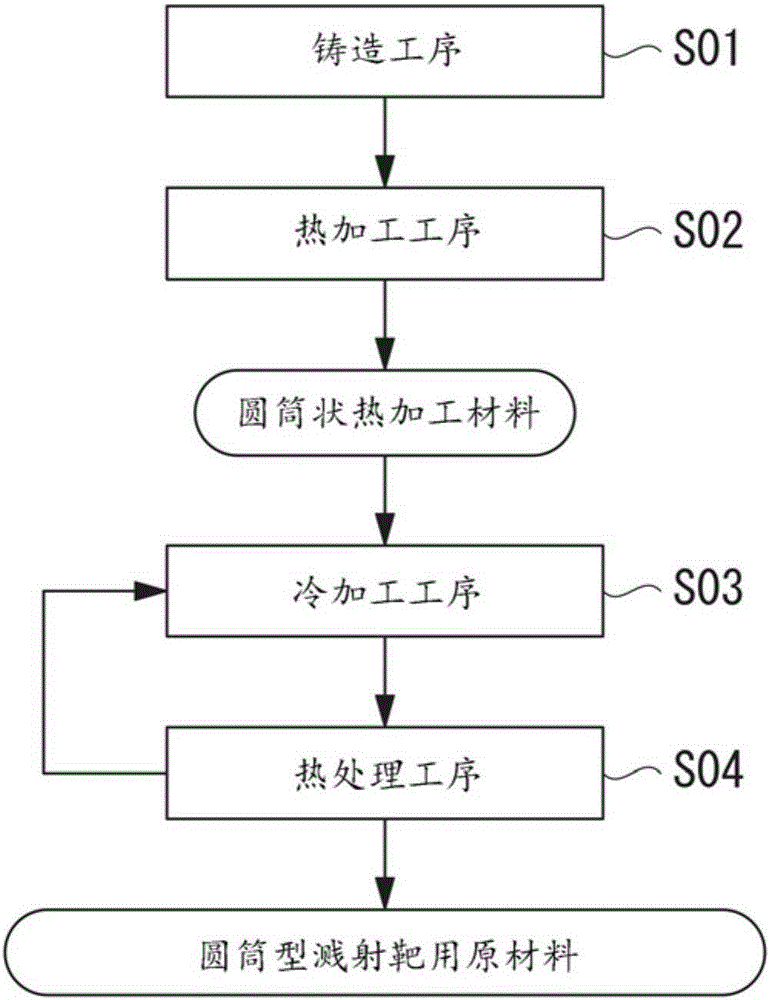

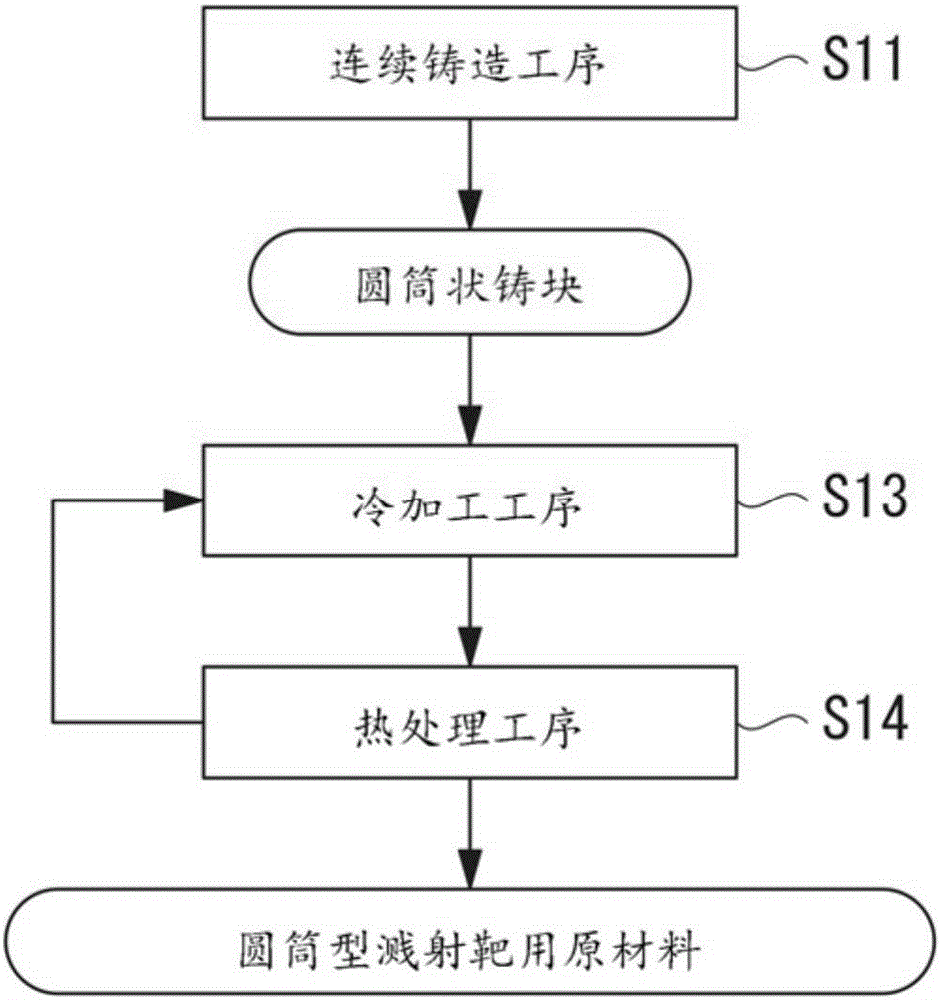

Method used

Image

Examples

Embodiment

[0062] Hereinafter, the results of confirmation experiments conducted to confirm the effectiveness of the present invention will be described.

[0063] First, a cylindrical ingot made of copper or a copper alloy having the composition shown in Table 1 was produced by a vertical continuous casting machine. At this time, the amounts of C, Si, and O as impurities in the copper melt were adjusted. In addition, electrolytic copper having a Si content of less than 10 mass ppm and a C content of less than 5 mass ppm was used as a raw material. In addition, in order to suppress the incorporation of Si during melting casting, the temperature during melting casting is set to 1200° C. or lower, which is a temperature at which Si does not melt out of the furnace material, etc., and the parts that become high temperature parts are made of alumina-based refractories. In addition, in order to suppress the increase of C content, the atmosphere in the furnace during preheating, melting, and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com