Method for jointing and caulking construction of concrete face rockfill dam face

A technology for concrete slabs and rockfill dams, applied in water conservancy projects, marine engineering, construction, etc., can solve problems such as low compaction efficiency, poor quality, and difficult compaction, so as to avoid filler pollution, improve construction efficiency, and reduce The effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

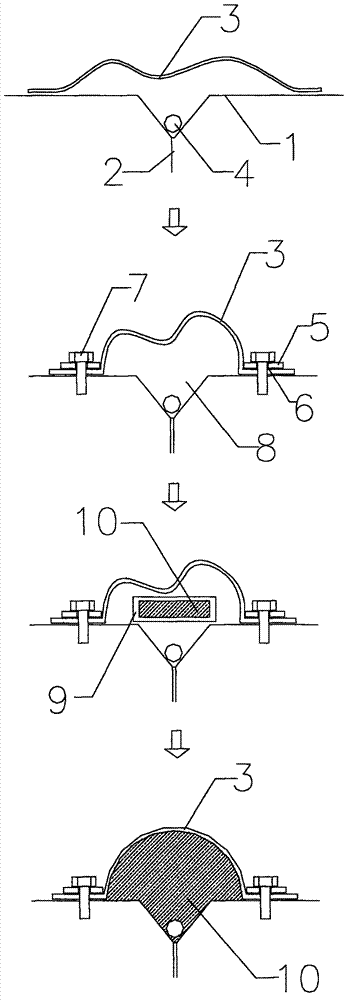

[0019] Such as figure 1 As shown in the schematic diagram of the construction process, the protective cover 3 is located just above the joint surface 2 of the concrete face rockfill dam panel 1, and the protective cover 3 is connected with the metal bead 5 and the bolts 7 passing through the reserved hole 6 of the metal bead. Fixed on the concrete panels 1 on both sides of the joint surface, so that the protective cover 3 and the concrete panel form a cavity 8 along the joint surface. Before the protective cover 3 is in place, the glue stick 4 should usually be fixed first. When the protective cover 3 is fixed, the fixed position of the metal bead 5 and the bolt 7 and the width of the convex part of the reserved protective cover 3 are determined according to the outer contour shape of the section of the flexible filler 10 to be embedded in the fourth process. Manually and / or mechanically press the flexible filler 10 for caulking into the cavity 8 through the glue injection por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap