Wind power dual hydraulic control pitch system

A pitch control system and hydraulic control technology, which is applied in the control of wind turbines, wind power generation, wind turbines, etc., can solve the problems of high control energy consumption, high consumption, and low control accuracy, and achieve stable pitch control, Reduce the effect of controlling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

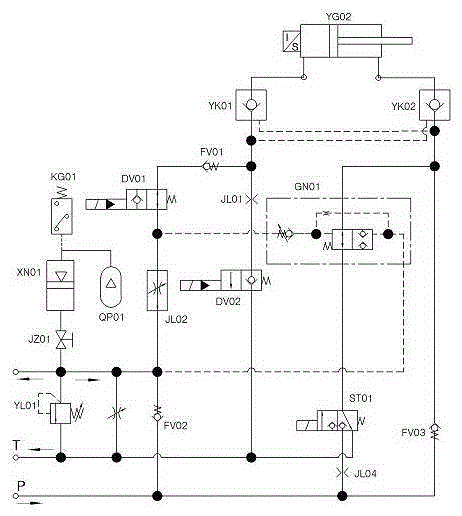

[0021] Such as figure 1 As shown, a dual-hydraulic pitch control system for wind power generation provided by the embodiment of the present invention is characterized in that it includes a basic pitch cylinder YG02, an oil supply check valve FV02, an oil supply accumulator XN01, and an oil inlet into chamber A Throttle valve JL02, B cavity control valve ST01, speed control valve GN01, A cavity hydraulic control check valve YK01, B cavity hydraulic control check valve YK02;

[0022] The pitch-changing basic cylinder YG02 is a single piston rod hydraulic cylinder;

[0023] The oil inlet of the oil supply check valve FV02 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com