Hydraulic coupler over-temperature protection device and repairing method thereof

A technology of hydraulic coupling and over-temperature protection, which is applied in transmission devices, fluid transmission devices, belts/chains/gears, etc. It can solve problems such as difficult cleaning, potential safety hazards, and pollution in the work area, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

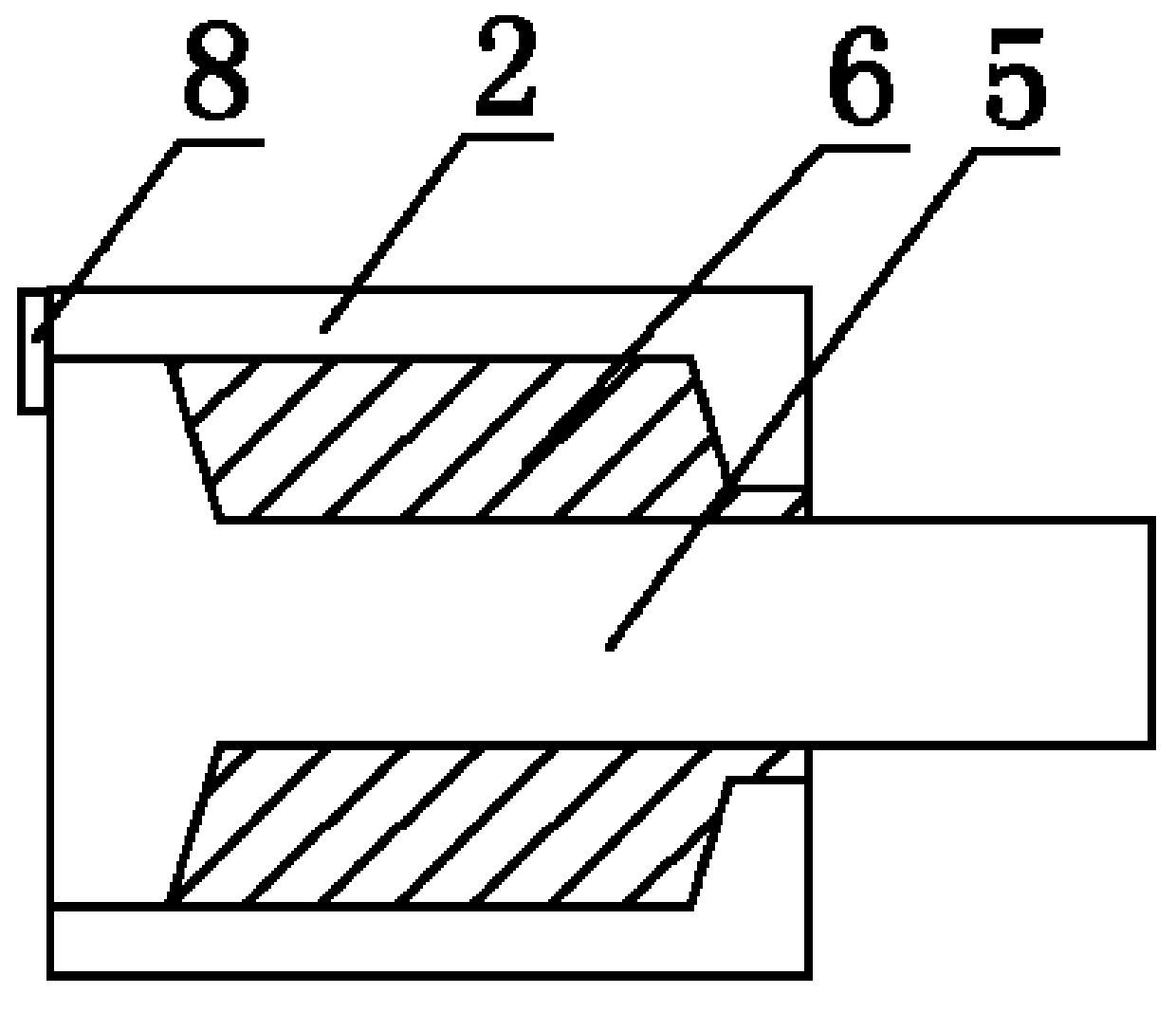

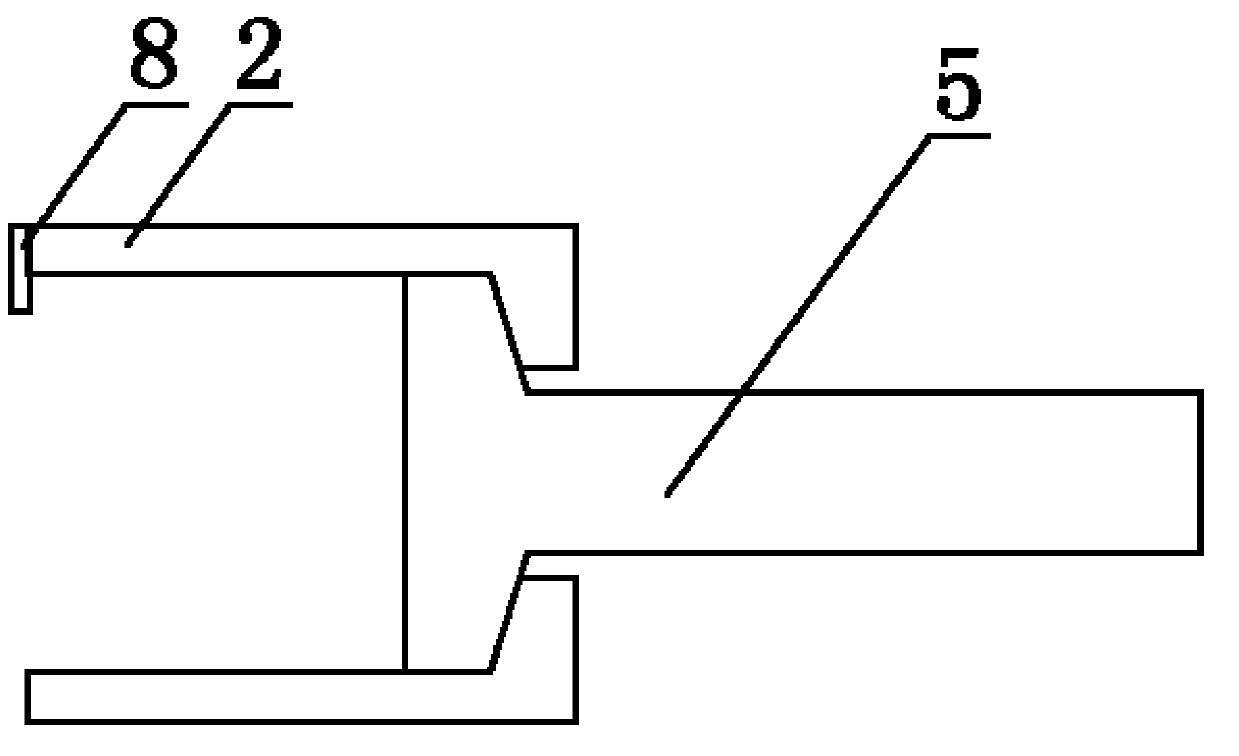

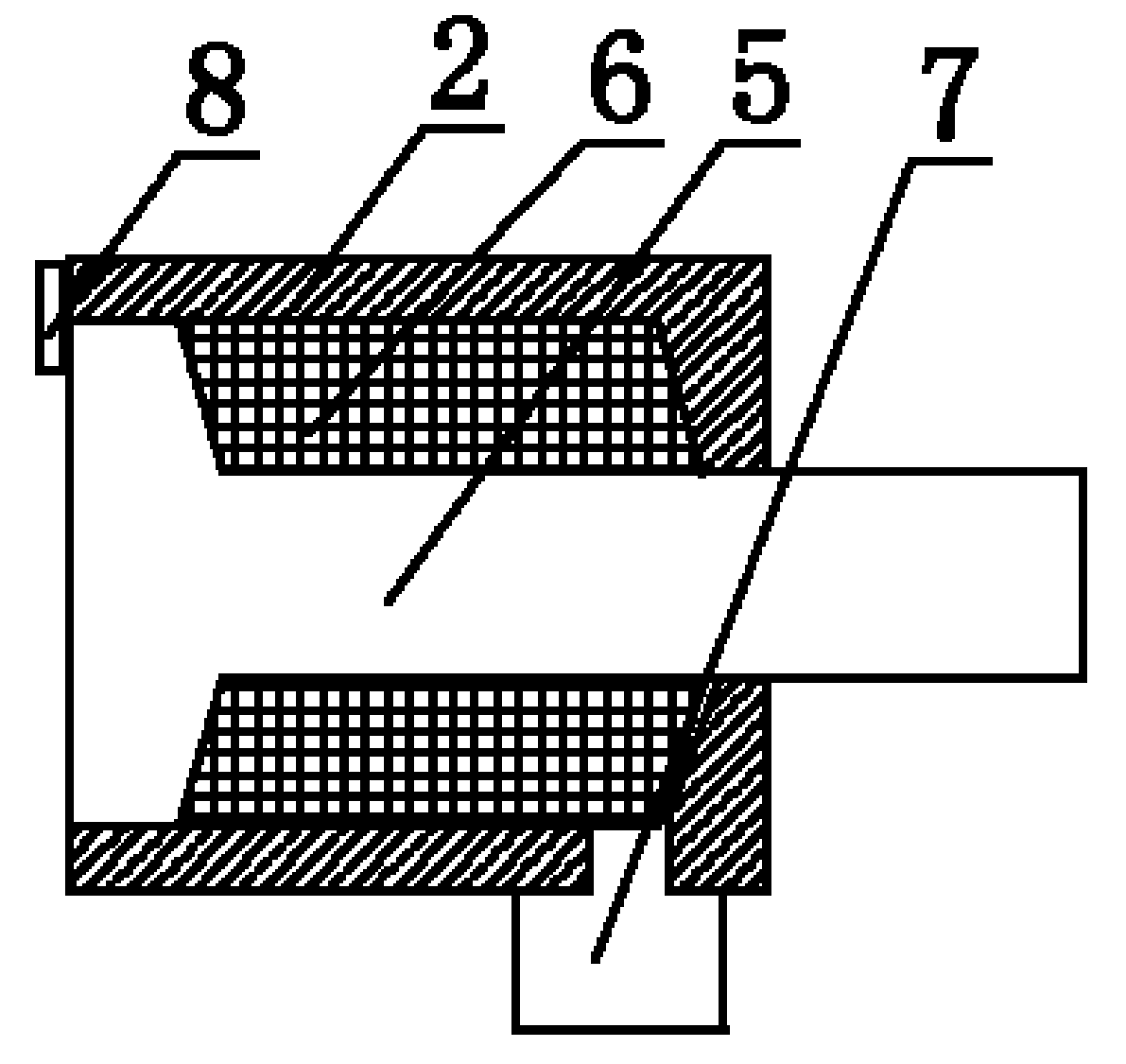

[0019] Embodiment 1: as Figure 1 to Figure 3 In the hydraulic coupler over-temperature protection device shown, the fusible plug 2 is detachably connected to the hydraulic coupler, its cylinder is connected with the hydraulic oil chamber 1, the proximity switch 3 is connected to the mounting bracket 4, and the mounting bracket 4 It can be arranged on the base of the driving device, and the connection between the proximity switch 3 and the bracket 4 and / or the connection between the bracket 4 and the base adopts a detachable connection method, so that the proximity switch 3 and / or the installation bracket 4 are connected to the fusible plug The distance between 2 is adjustable. The sensing head of the proximity switch 3 is located near the side of the fusible plug 2 , and the sensing head of the proximity switch 3 coincides with the central axis of the fusible plug 2 during initial installation. Such as Figure 4 and Figure 5 As shown, in this embodiment, the fusible plug ...

Embodiment 2

[0022] Embodiment 2: as Figure 1 to Figure 3 In the hydraulic coupler over-temperature protection device shown, the fusible plug 2 is fixedly connected to the hydraulic coupler, its cylinder is connected to the hydraulic oil chamber 1, and the proximity switch 3 is connected to the mounting bracket 4, which can be set On the base of the driving device, the connection between the proximity switch 3 and the bracket 4 and / or the connection between the bracket 4 and the base adopts a detachable connection mode, so that the proximity switch 3 and / or the installation bracket 4 and the fusible plug 2 The distance between them is adjustable. The sensing head of the proximity switch 3 is located near the side of the fusible plug 2 , and the sensing head of the proximity switch 3 coincides with the central axis of the fusible plug 2 during initial installation. Such as Figure 6 and Figure 7As shown, in this embodiment, the fusible plug 2 includes a cylinder fixed on the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com