white light led lighting device

A technology for light-emitting devices and LED chips, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of decreased luminous intensity of phosphors, drift of luminous wavelengths of phosphors, and increased operating temperature of devices, so as to avoid the decrease of luminous efficiency of devices. , The effect of alleviating luminous wavelength drift and luminous intensity decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

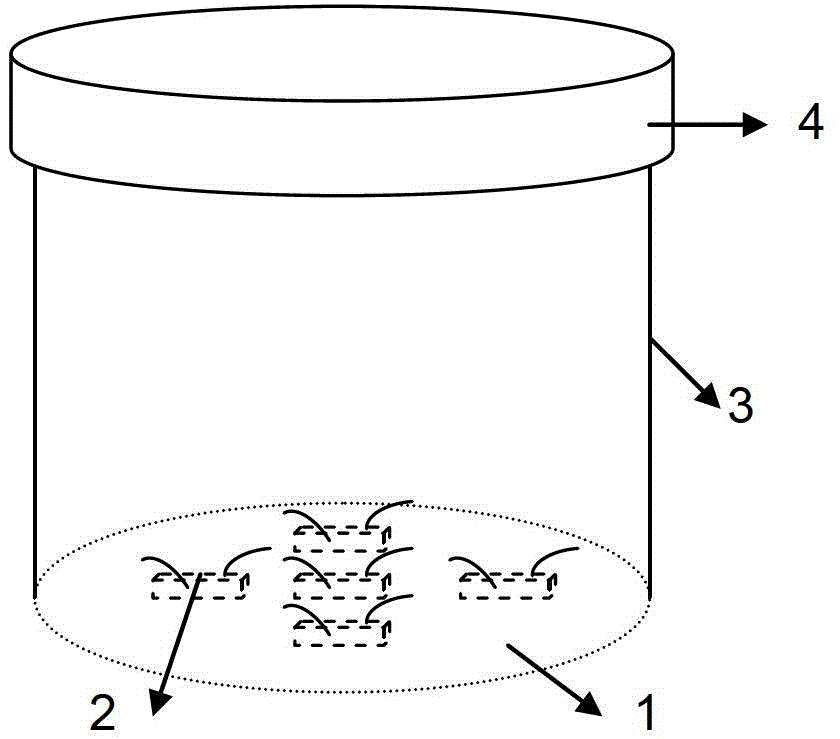

[0051] figure 1 It is a schematic diagram of a white LED lighting device according to Embodiment 1 of the present invention. The white LED lighting device includes: a base 1 , a blue LED chip 2 , a reflector 3 and a substrate 4 . Both ends of the reflector 3 are respectively connected to the base 1 and the substrate 4, the blue LED chip 2 is arranged on the side of the base 1 facing the substrate 4, and the electrode leads of the blue LED chip 2 pass through the base 1, and one surface of the substrate 4 is coated with Phosphor-containing organic coatings.

[0052] As one of the specific embodiments, in order to obtain white light, the phosphor may be LED yellow phosphor. In order to improve the color rendering index of white light, the phosphor can also be a mixture of LED green phosphor and LED red phosphor in any proportion, or a mixture of LED yellow phosphor and a small amount of LED red phosphor. The luminous color, or the color temperature, can be adjusted by adjusti...

Embodiment 2

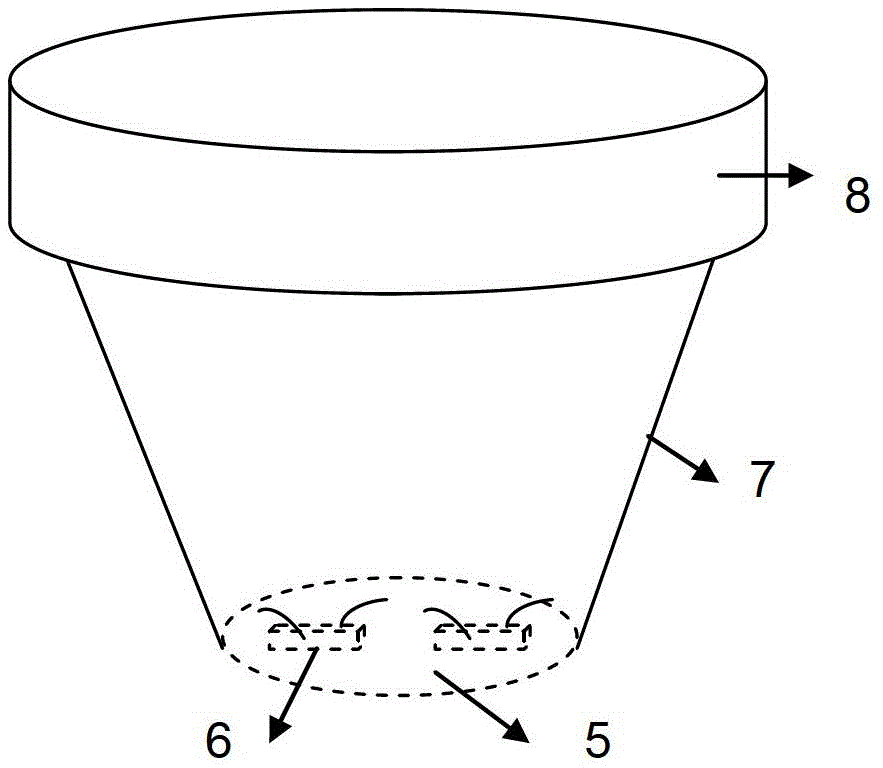

[0060] by figure 2 It is a schematic diagram of the white LED lighting device of Example 2.

[0061] The difference between this embodiment and Embodiment 1 is that the reflector 7 is in the shape of a rounded truncated cone, the base 5 is used as the lower bottom of the rounded truncated truncated shape, and the substrate 8 is used as the upper bottom of the rounded truncated truncated shape.

Embodiment 3

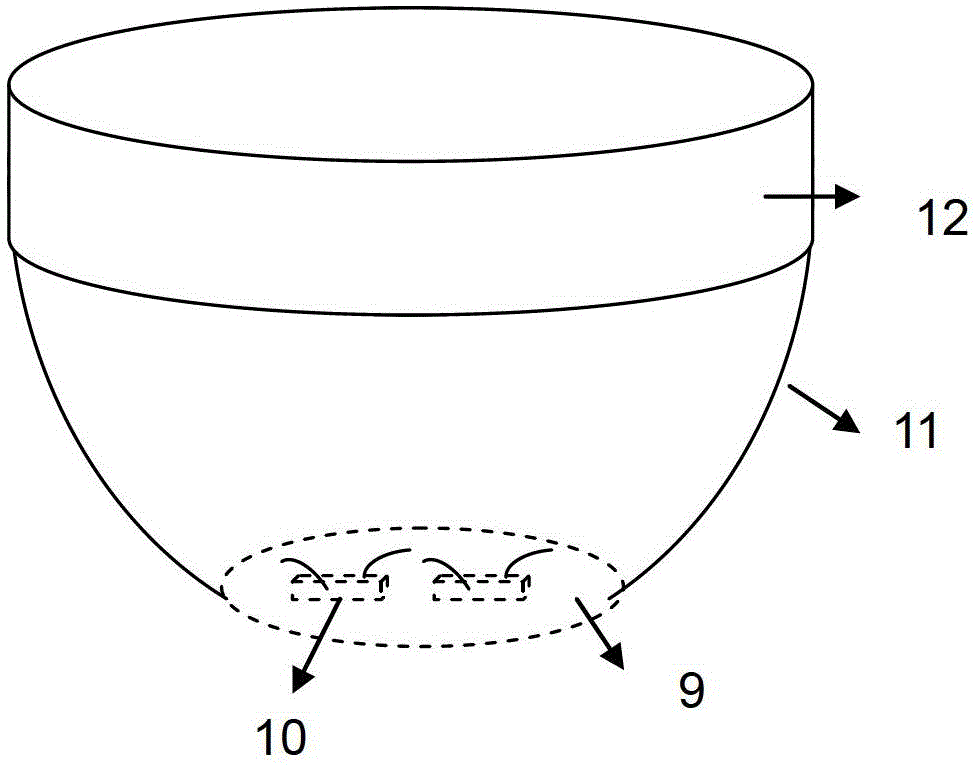

[0063] by image 3 It is a schematic diagram of a white LED lighting device according to Embodiment 3 of the present invention.

[0064] The difference between this embodiment and Embodiment 1 is that the reflector 11 is in the shape of a bowl, the base 9 serves as the bottom of the bowl, and the base plate 12 is located at the mouth of the bowl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com