Wind direction stable spraying pelleting device

A technology of stabilizing device and granulating device, which is applied in the direction of liquid separation into bead droplets and granulation, which can solve problems such as sticking to the tower wall, and achieve the effect of ensuring the direction of movement, uniform granulation, and avoiding direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

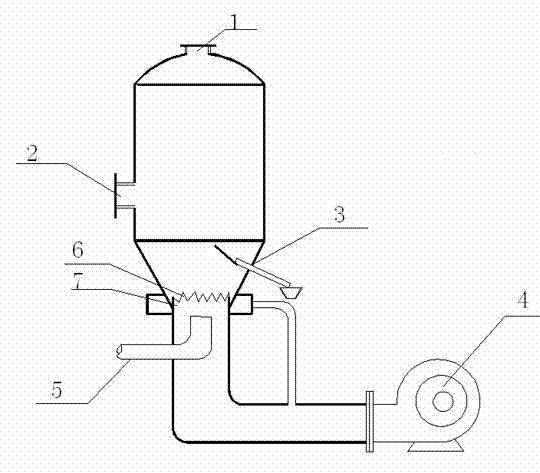

[0007] A wind-direction-stabilized spray granulation device of the present invention has a granulation tower, the upper end of the granulation tower is provided with an air inlet 1 and an induced draft fan, the lower part of the granulation tower is provided with a conical bottom, and the lower end of the conical bottom is provided with a blower port. The blowing port has a conduit 5 for introducing liquid raw materials. The conduit communicates with the liquid raw material container, and the side wall has a secondary air inlet 2. It is characterized in that: the side wall of the cone bottom has a discharge port 3, and the lower end of the cone bottom has a granulation blower. The air outlet of tube 7. The air outlet at the upper end of the blower is connected with a serrated circle 6 with corrugated teeth on the surface. The zigzag circle 6 is connected with the original air outlet 7, so that the blown wind does not fluctuate and the wind direction is stable. Cooling and gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com