Device and method used for cleaning chamber before etching process

A cleaning and process technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as poor products, increase cleaning costs, and reduce fault tolerance of production lines, so as to increase process time, extend maintenance cycles, and reduce products. bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

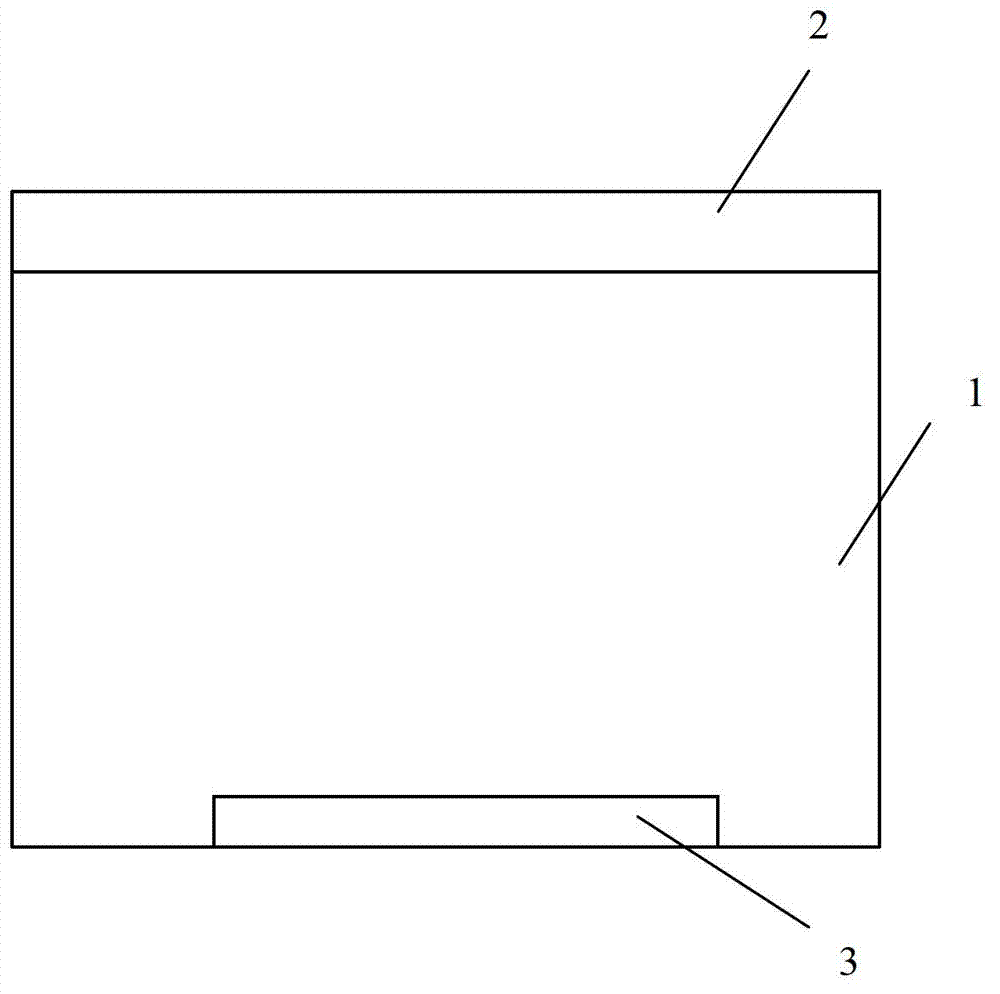

[0030] Embodiment 1 of the present invention provides a device for cleaning the substrate before the etching process, which is used to optimize the environment in the chamber to be dry-etched and reduce particle pollution in the chamber. The device is a cuboid vacuum The chamber includes a chamber body 1 for placing and transferring an array substrate 3 . The vacuum chamber also includes a chamber cover 2 arranged on the chamber body 1, the chamber cover 2 is an insulating material, and the device also includes liftable pillars (not shown) located in the chamber body 1 shown), a reaction table (not shown) located in the chamber body 1 for absorbing the substrate. The chamber has a length of 2700mm-2800mm and a width of 2400mm-2500mm. Preferably, the chamber has a length of 2700mm and a width of 2400mm.

[0031] The structure of the device in this embodiment is simple, and it can be used to clean the internal environment of the chamber itself before dry etching without adding ...

Embodiment 2

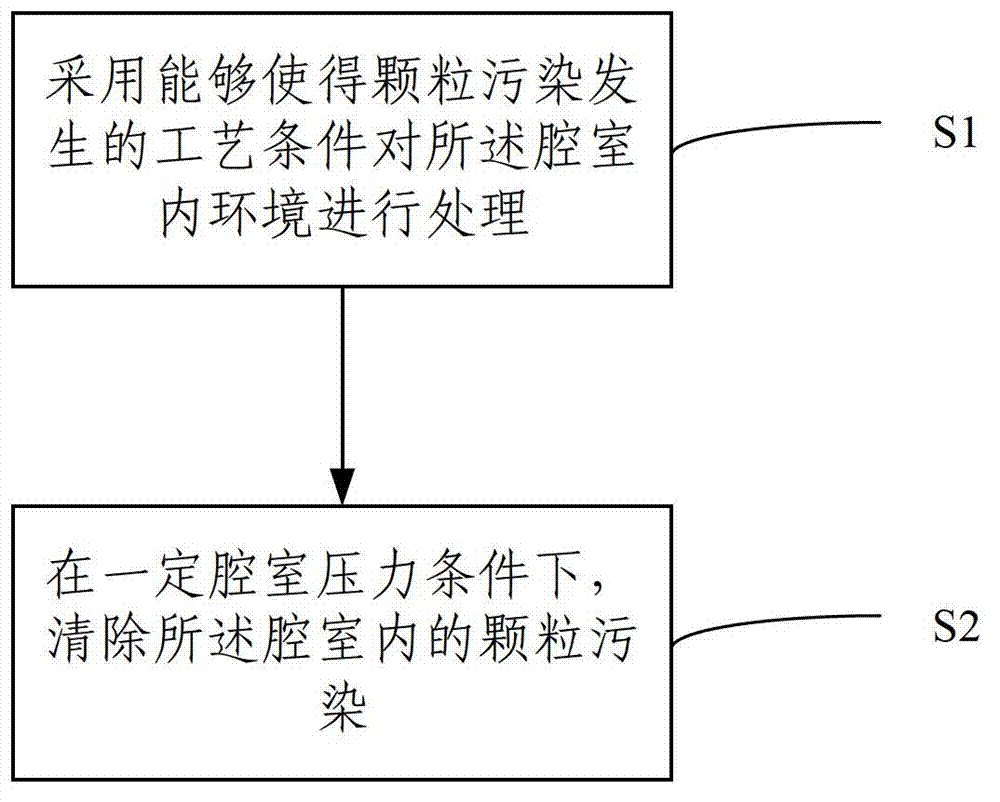

[0033] Embodiment 2 of the present invention also provides a method for cleaning a chamber using the device described in Embodiment 1, including two steps:

[0034] S1. The environment inside the chamber is treated by adopting process conditions where particle pollution is likely to occur. Specifically, by setting the pressure of the chamber, before the array substrate enters the chamber, an aggravated condition of particle pollution that easily induces the reaction product on the inner wall of the chamber to fall off is formed.

[0035] The process conditions of step S1 are: chamber pressure 5-200mt, electrode power 5000-18000W, reaction gas selected from O 2 、CL 2 , SF 6 , He or a combination of several, the total gas flow is 5000-20000 sccm.

[0036] In a further solution, the process conditions of step S1 are: chamber pressure 5-100mt, electrode power 7000-16000W, total gas flow rate 8000-15000sccm.

[0037] S2, removing particle pollution. Specifically, ultra-low cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com