Transmission device of top cross 45-degree continuous rolling machine unit

A transmission device and continuous rolling technology, which is applied to the driving device for metal rolling mills, metal rolling, metal rolling, etc., can solve the problems of inconvenient maintenance, and achieve the effect of convenient maintenance and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

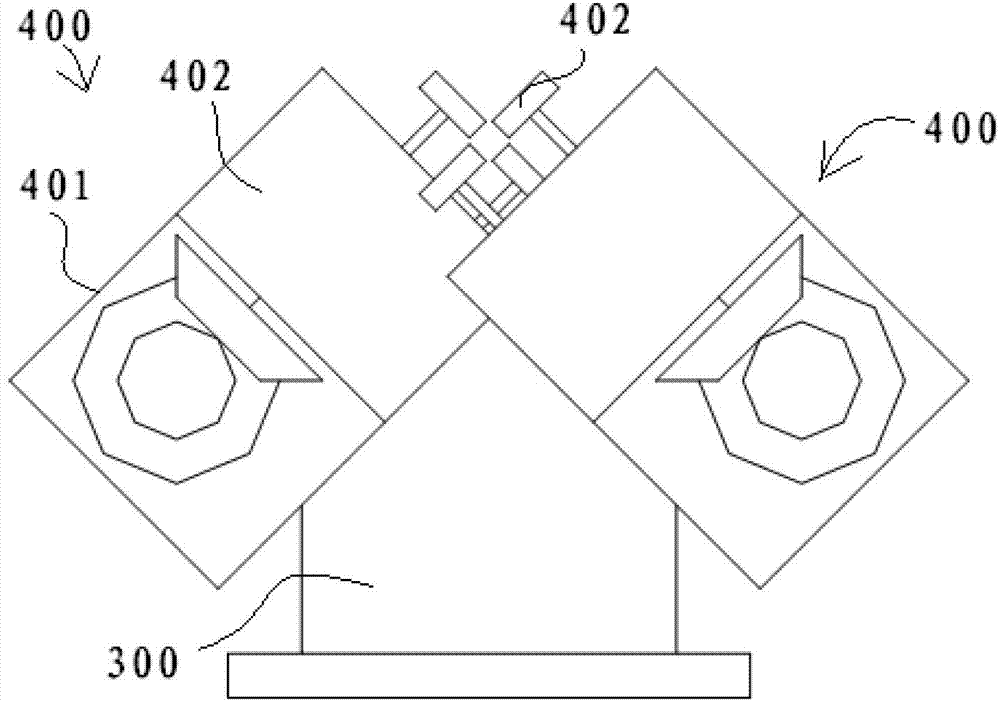

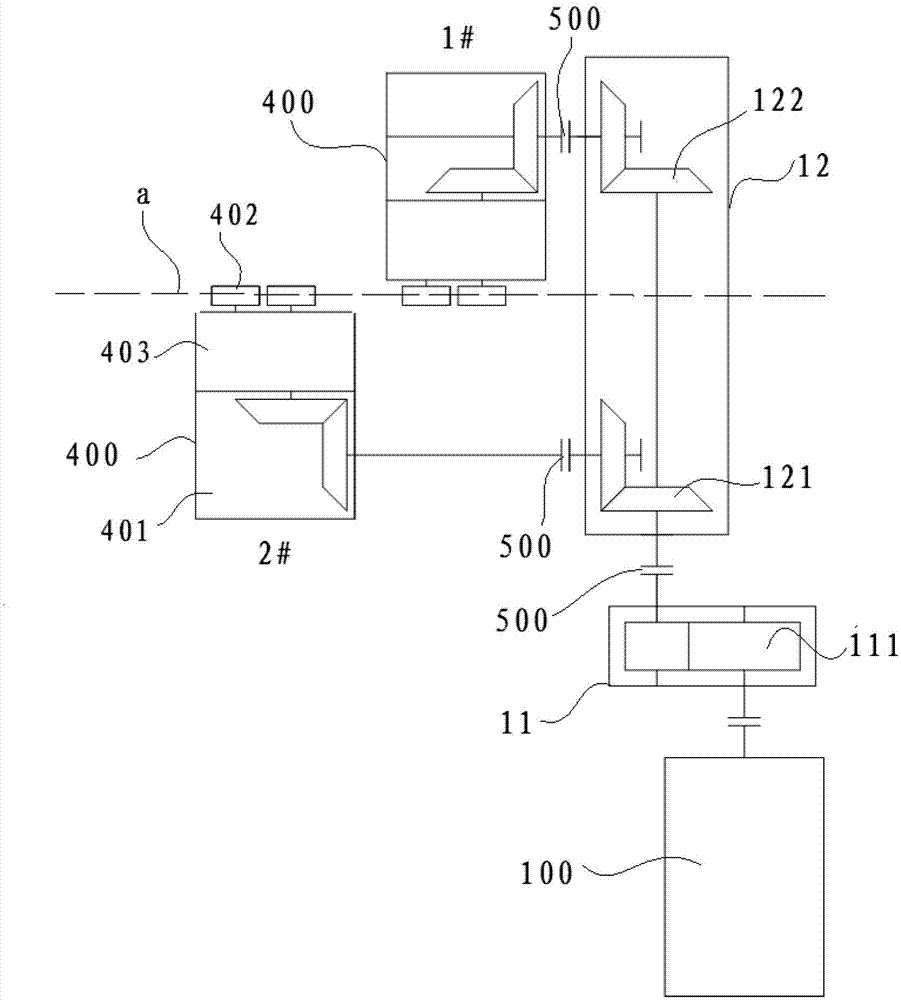

[0082] Such as image 3 As shown, in this embodiment, the transmission device of the top cross 45° continuous rolling mill unit of the present invention is used to provide power for the top cross 45° continuous rolling mill with two stands of 1# and 2# stands.

[0083] The 1# and 2# stands of the top cross 45° continuous rolling mill adopt the top cross 45° arrangement, and they are set at 90° to each other. The driving motor 100 is arranged on the side of the rolling centerline a of the top-crossing 45° continuous rolling mill, and the output shaft of the driving motor 100 is perpendicular to the rolling centerline a, and the input shaft of the speed increasing box 11 and the output of the driving motor 100 The shafts are coaxially connected by a coupling 500. The output shaft of the speed increaser and the input shaft of the bevel gear distribution box 12 are connected by a coupling 500. The two output shafts of the bevel gear distribution box 12 are respectively connected to th...

Embodiment 2

[0090] Such as Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is that the transmission of the top cross 45° continuous rolling mill in this embodiment eliminates the speed increasing box 11, and the output shaft of the driving motor 100 is directly connected to the bevel gear distribution box 12. The input shaft is connected by a coupling 500.

Embodiment 3

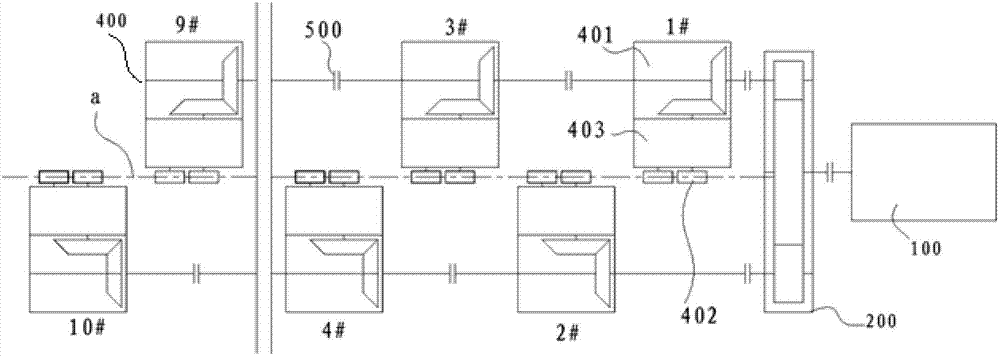

[0092] Such as Image 6 As shown, the top cross 45° continuous rolling mill in this embodiment includes a rolling mill with a total of four stands of 1# stand, 2# stand, 3# stand and 4# stand and two sets of the present invention The transmission device of the top cross 45° continuous rolling mill. In order to ensure that the four racks have the smallest and the same spacing, of the two sets of transmission devices of the top cross 45° continuous rolling mill, one set of the transmission device is set at the entrance side of the top cross 45° continuous rolling mill to drive 1# machine Frame and 3# frame, another set of the transmission device is set on the exit side of the top cross 45° continuous rolling mill, and drive 2# frame and 4# frame.

[0093] In this embodiment, the gear ratio configuration scheme of each gear pair is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com