Horizontal lathe device with chuck capable of being clamped and released automatically

A horizontal lathe and automatic clamping technology, applied in auxiliary devices, accessories of tool holders, turning equipment, etc., can solve the problems of low production efficiency, prone to failure, complex structure, etc., and achieve simple structure, high production efficiency, Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

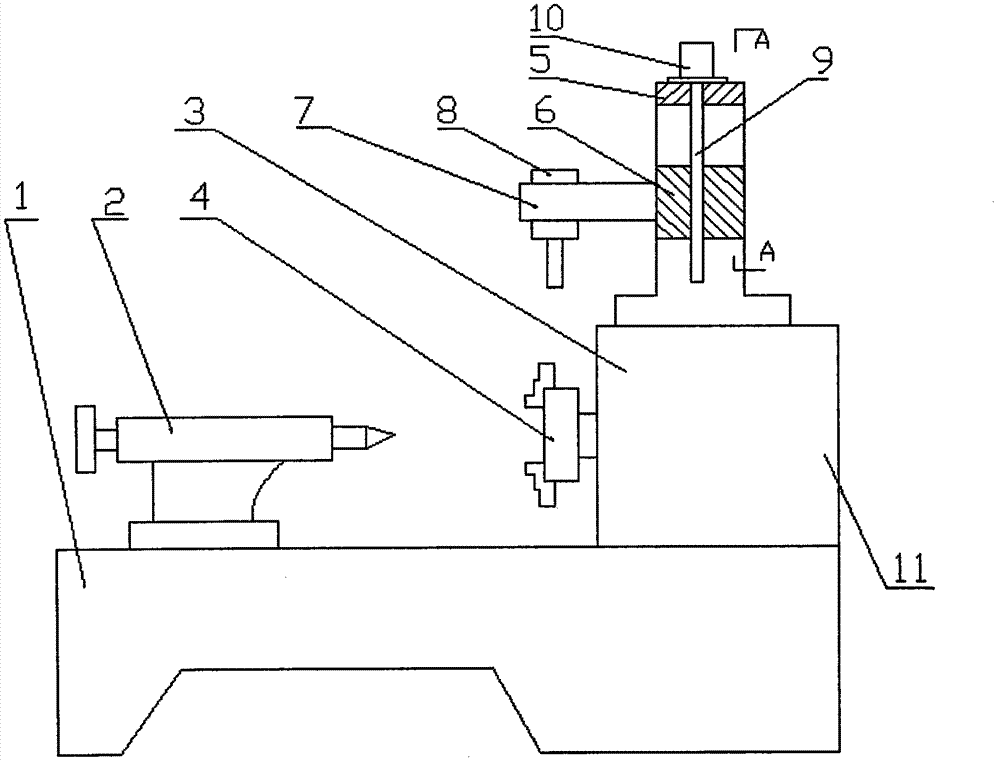

[0009] The lathe seat 1, the tailstock 2, the headstock 3 and the chuck 4 are combined to form a horizontal lathe, the portal column 5 is fixed and installed on the headstock 3 with bolts, and the slider 6 is installed on the opening of the portal column 5. In the middle, the cantilever 7 is fixedly connected with the slider 6, the air wrench 8 is installed and fixed on the cantilever 7, the air motor 10 is installed and fixed on the top of the portal column 5, and the upper end of the lead screw 9 is fixedly connected with the output shaft of the air motor 10, The other end is connected with the slide block 6 through threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com